This article is part of the

SPRING 2023 R&D NEWSLETTER

In This Issue

A robotic arm imitates the wind. A soil box mimics the sea floor. And a grid simulator emulates weather and electrical events.

All three of these impersonators at Lehigh University, Clemson University, and Oregon State University represent new hybrid testing capabilities for offshore wind energy systems made possible with funding from the U.S. Department of Energy’s (DOE) Wind Energy Technologies Office (WETO). Full-scale, on-site physical testing of offshore wind energy technologies is logistically difficult, expensive, and time-consuming for early evaluation of design concepts. To simulate real-life situations, WETO funded facilities at three universities to test offshore wind energy components in a laboratory setting.

“Our hope is that these facilities can support a nationwide capability for testing offshore wind energy technologies,” said Monica Maher, WETO offshore wind energy specialist. “This will help the United States reach its national goal of achieving 30 gigawatts of offshore wind energy by 2030 and further inspire industry trust in offshore wind energy systems.”

These facilities enable hybrid testing, which combines the benefits of both physical field tests and computerized simulations, to capture the broadest, most reliable information about offshore wind energy systems.

“A wide range of scenarios can be tested in a relatively short hybrid testing campaign. In addition, setting wind and wave settings enables testing for extreme storms and other abnormal conditions, which may not occur during long field-testing campaigns,” Maher said. “With WETO-funded upgrades, these hybrid test facilities will help address unique U.S. offshore challenges and improve the reliability of offshore wind systems.”

Awarded through a 2019 funding opportunity announcement, the three hybrid offshore wind energy testing facilities will help improve the reliability of offshore wind energy systems by enabling researchers to test their physical component designs under a variety of wind and wave conditions. Unique wind speeds could be simulated based on a specific event of interest or to reflect a certain offshore location.

Principal investigator Muhannad T. Suleiman (front) stands with the Lehigh University research team responsible for developing a hybrid research capability that enables them to measure how a wind turbine support structure interacts with surrounding soil. The group stands above a 12-foot-deep soil box they developed with WETO funding.

Lehigh University Takes a Ground-Up Approach

With WETO funding, Lehigh University in Bethlehem, Pennsylvania, built a hybrid research facility within its Advanced Technology for Large Structural Systems Engineering Research Center that tests interactions between offshore wind turbine foundations and their surrounding soil. The facility combines the computer model OpenFAST—an engineering tool that mimics the dynamic responses of air, water, control and electrical systems, and structural forces on offshore wind turbines—with physical testing to model the impacts of these forces on offshore wind turbine structures.

“The physical part of this research takes place in our soil-foundation interaction laboratory while the computer part uses OpenFAST to model the wind and waves,” said Muhannad T. Suleiman, a Lehigh University civil and environmental engineering professor and the project’s principal investigator. “With both the physical and computer parts running at the same time, this is a real-time hybrid simulation that gives us the behavior of the whole wind turbine system.”

The testing setup for soil-foundation interaction is a steel-framed box about the size of a bedroom in a house—12 feet deep, 12 feet wide, and 15 feet long—set inside the existing research center. Sandy soil fills the box, representing the seabed. A small-scale structure, such as a foundation or anchor, is set in the sand, and actuator devices push on the test structure.

Suleiman’s multidisciplinary research team also developed a model that virtually applies specific wind, water, and mechanical conditions, calculated using OpenFAST, to the model turbine. Researchers then measure how the turbine support structure interacts with the surrounding soil using sensors that are placed on the structure and in the sand.

“DOE funding gave us an opportunity to expand on our expertise and upgrade our testing facilities to study the interactions between fluid, soil, foundation, and structures of offshore support structures,” Suleiman said. “Our holistic approach is unique because we are looking at the behavior of the whole wind turbine structure—including its foundation support system—from the ground up.”

One of the main goals of this work, he said, is to establish the Advanced Technology for Large Structural Systems Engineering Research Center as a place where researchers and scientists can better understand offshore wind energy structures under different conditions and ultimately help advance the industry.

The Lehigh University team is preparing for their first lab-scale test using the new soil box. Next, they plan to host a workshop for wind energy industry members interested in using the facility. Please email Mts210@lehigh.edu for additional information.

Clemson University Completes the Picture Using a Digital Twin

When manufacturers want to evaluate wind turbine gearbox or drivetrain designs for reliability, they come to drivetrain test facilities like Clemson University’s in North Charleston, South Carolina. This WETO-funded facility provides manufacturers with critical information to improve their designs and advantages over field tests by offering full-scale, highly accelerated mechanical and electrical testing of advanced wind turbine components in a controlled environment.

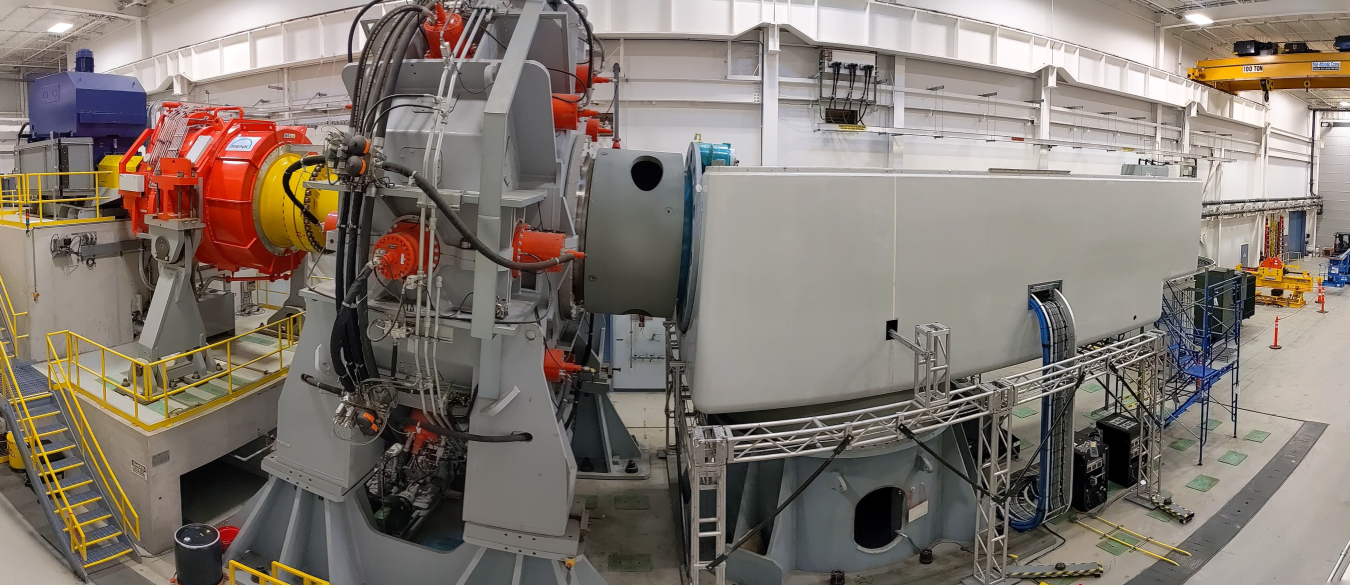

It had its disadvantages, too, because tests on mechanical and electrical systems could not be conducted at the same time. However, thanks to WETO funding, Clemson’s 7.5-megawatt and 15-megawatt dynamometers can conduct hardware-in-the-loop testing—meaning simultaneous mechanical, electrical, and controller validation of offshore-scale wind turbine systems.

WETO funding enabled Clemson University to upgrade its 7.5-megawatt and 15-megawatt dynamometers so they can conduct simultaneous mechanical, electrical, and controller validation of offshore-scale wind turbine systems.

“With offshore wind turbines, electromechanical interactions are very important,” said Amin Bibo, the Clemson University principal investigator for these facility improvements. “Hardware-in-the-loop testing provides a way to synchronize mechanical and electrical testing, which enables us to test turbine functionality of the whole turbine in a more realistic environment.”

Bibo explained that hardware attached to a dynamometer—which measures force, torque, or power— for testing can now be run in parallel with a computer model (called a digital twin) of the wind turbine. This model mimics—and compensates for—any turbine components missing from the physical test while enabling the wind turbine controller (which operates the turbine’s electrical and mechanical systems) to communicate with the simulation model.

“This real-time simulation accelerates design validation. We can simulate wave and wind conditions for offshore wind turbines, and if we want to model electrical conditions—such as a transmission failure—we just specify those conditions in the computer,” Bibo said. “This is a much more realistic test that forwards the progress of wind turbine design and control to increase the resiliency and reliability of future offshore wind turbines.”

Clemson University’s hardware-in-the-loop testing capability is ready for industry use. Wind turbine manufacturers interested in using the facility can contact vpr@clemson.edu.

Oregon State University graduate student Akiri Seki sits next to a robotic arm attached to the top of a small-scale floating offshore wind energy platform in the university’s wave research laboratory. The arm receives computer data to mimic the wind on the tower, enabling researchers to conduct real-time hybrid research of wind and waves. Seki paddled out to the ladder using the surfboard beneath him.

Oregon State University Arms Its Wave Tank with Wind

Oregon State University’s O.H. Hinsdale Wave Research Laboratory in Corvallis, Oregon, features the largest nonmilitary wave facility in North America, capable of making waves that reach almost 6 feet in height to depict what might happen in fierce ocean storms and even tsunamis. Here, researchers study how waves affect offshore and coastal structures, including offshore wind turbines.

Aerodynamic and hydrodynamic (or wind and wave) loads scale differently, making it challenging to design small-scale physical experiments that use a wave basin and fans. Simulating some loads in a computer model allows for better scaling. “Our wave tank replicates hydrodynamics with waves and floating wind platforms, but not physical wind effects,” said Bryson Robertson, Oregon State University professor of civil and construction engineering and director of the Pacific Marine Energy Center. “So, we’re bypassing this flaw by generating or applying waves in the real world, and wind in the numerical world.”

With funding from WETO, Robertson brought together a diverse team of researchers with expertise in hydrodynamics, robotics, hybrid simulators, machine learning, and offshore wind energy systems. They pooled their knowledge to create a hybrid testing system that couples physical waves and modeled wind effects.

These tests are performed on small-scale prototypes of wind turbines. Aerodynamic (wind) and hydrodynamic (wave) loads scale differently, making it challenging to design small-scale physical experiments that accurately portray ocean-sized conditions using a wave basin and fans. Simulating some loads in a computer model allows for better scaling.

Joining the physical and virtual worlds is a robotic arm purchased with WETO funding. Attached to a superstructure above the wave tank, the arm grabs the top of the floating offshore wind platform. The wave tank produces waves that cause the turbine tower to move. OpenFAST software computes wind impacts and speeds, which are communicated to the robotic arm.

“The arm attaches to the top of the wind turbine tower, follows the movement caused by waves, and additionally pushes the tower as though it were wind,” Robertson said. “This real-time hybrid capability will be revolutionary for the floating offshore wind sector because it can really drive down the cost of testing these structures.”

Another benefit, Robertson said, is providing more equitable industry access to testing.

“This research will provide a lower barrier to entry for smaller and new developers, offering them a cost-effective way to test the validity of their concepts. Previously, that option hadn’t existed. You’d need deep financial pockets for a large-scale test,” he said. By the end of 2023, Robertson hopes to have the hybrid testing capability ready for industry use.

“WETO funding allowed us to move the needle on this research capability, which will accelerate floating offshore wind system testing to rapidly identify which concepts have potential and which don’t,” Robertson said. “This ensures investments are made in the most promising concepts and that design iterations can happen rapidly.”

If you are interested in using the Oregon State University facility, contact hinsdale@oregonstate.edu.

Spring 2023 R&D Newsletter

Subscribe to the WETO e-newsletter to stay informed on the latest wind energy news, events, publications, and updates.