Overview

Lehigh University Composites Lab has an excellent suit of equipment for design, analysis, optimization, manufacturing and testing of composite structures. There are a large number of workstations with computer aided design (CAD), finite element (FE), and structural optimization software. However, the heart of the lab is the manufacturing and experimentation equipment:

Composite Manufacturing

- Very large 5-axis CNC router (located on Mountaintop Campus)

- CNC abrasive waterjet cutter

- Large precision leveled vacuum infusion table

- Three smaller infusion tables

- 12 vacuum pumps

- Prepreg curing oven,

- Hand lamination tables

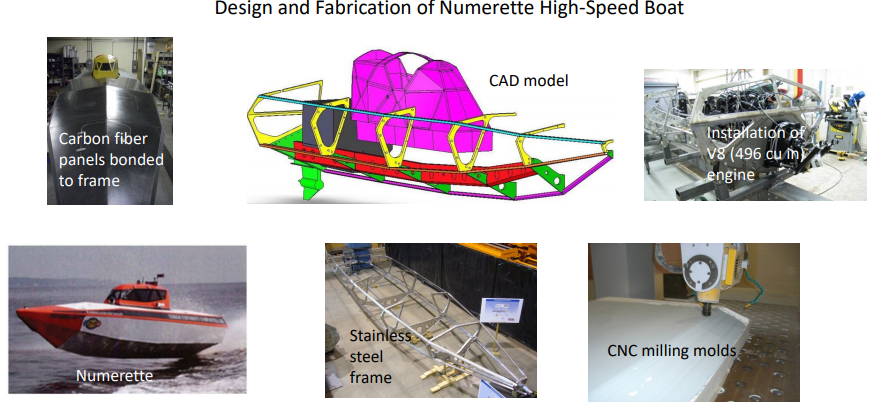

As well as all necessary tools. There is also a complete "boat lab" for manufacturing of manned experimental boats.

Experimental Testing

- Instron test frame

- Large drop weight impactor for impacting ship hull bottom panels

- Vibration identification system for measuring composite stiffnesses

- Environmental chamber

- Ultrasonic NDT equipment

- Signal conditioners for strain gages etc

- Large number of specialty fixtures for various structural tests

The lab is also equipped with most of the standard ASTM test fixtures for composites testing.

Larger Testing

- Manned fully aerobatic single seat aircraft for flight research

- Offshore two-seat catamaran raceboat for naval research

- Large number of remote control boats

Larger tests, such as the static sagging and hogging tests of a 6 meter steel/composite hybrid ship hull (designed and built inhouse), or the fatigue test of a 16 ton hybrid beam, are often coordinated with Lehigh's ATLSS center.

At present, a two-seat 9 meter high speed steel/composite hybrid boat is being built for slamming research

Rooms: Packard 165, 167 & 169

Faculty Contact: Joachim Grenestedt (jog5@lehigh.edu)

Staff Contact: Bill Maroun (wjm2@lehigh.edu)