Faculty within the MSE department have specialized laboratories and facilities geared towards specific research areas and accessible to all trained graduate students needing access to equipment for their research. Beyond the individual faculty member's specialized laboratories, extensive shared/core facilities exist. Some important larger scale facilities used for this research include:

Synthesis/Processing

-

Integrated Nanofabrication and Cleanroom Facilities (INCF): This facilities provides equipment necessary for processing of III-N, III-V, and silicon-based materials to go from etching, deposition to packaging and preliminary testing. It provides electron-beam and photo-lithography, intermixing/contact annealing, III-V and dielectric etchers, SiO2 and Si3N4 deposition, metalization and AR/HR, holography system, wet etching, wafer thinning, laser scribing, and basic laser packaging.

-

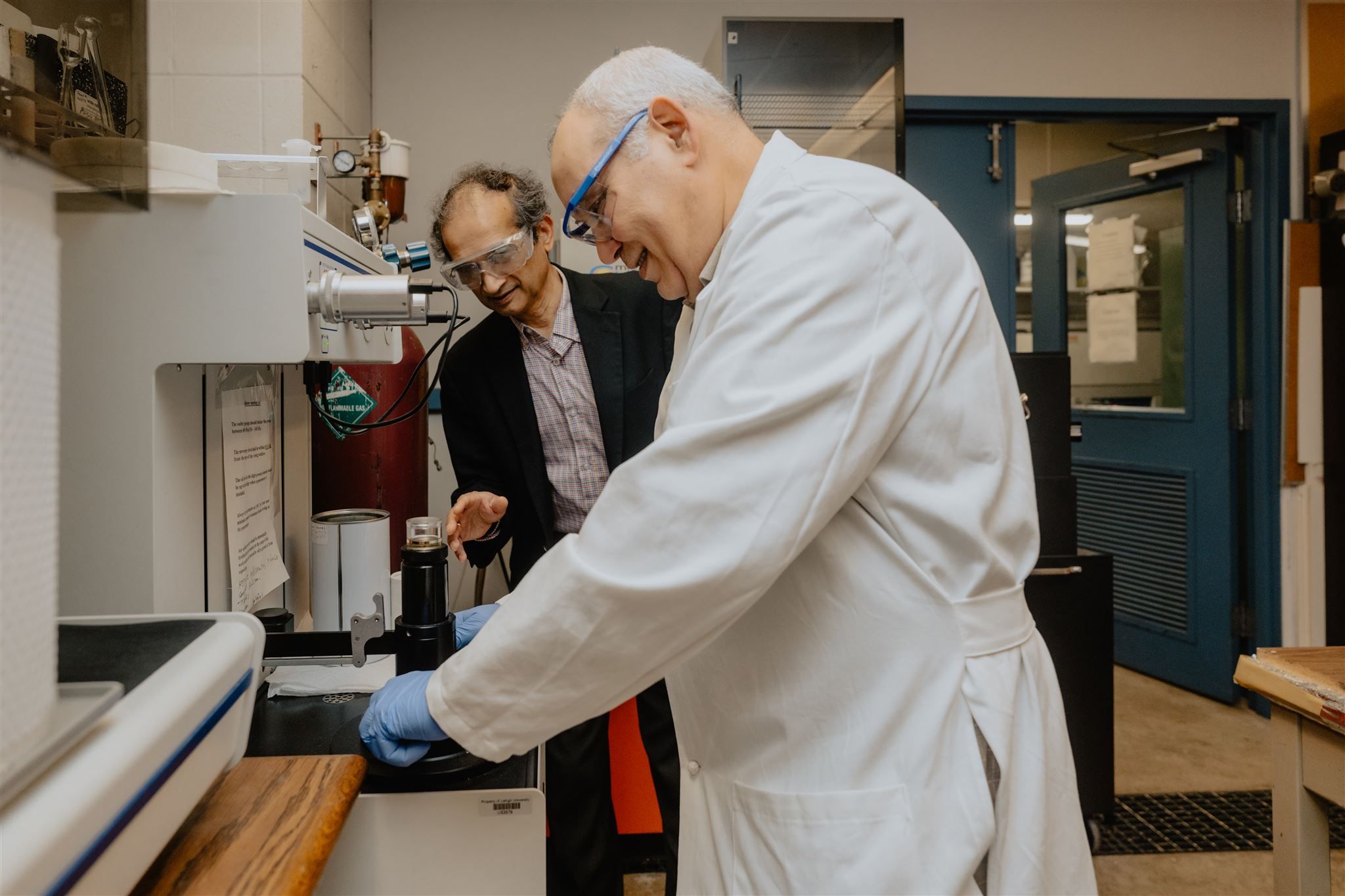

MOCVD Epitaxy and Synthesis Lab: Two MOCVD reactors support research on III-Nitride and III-V semiconductor material systems. Additional facilities exist to fabricate organic photonics, phosphors and nanoparticles for fundamental studies and device fabrication and prototyping.

-

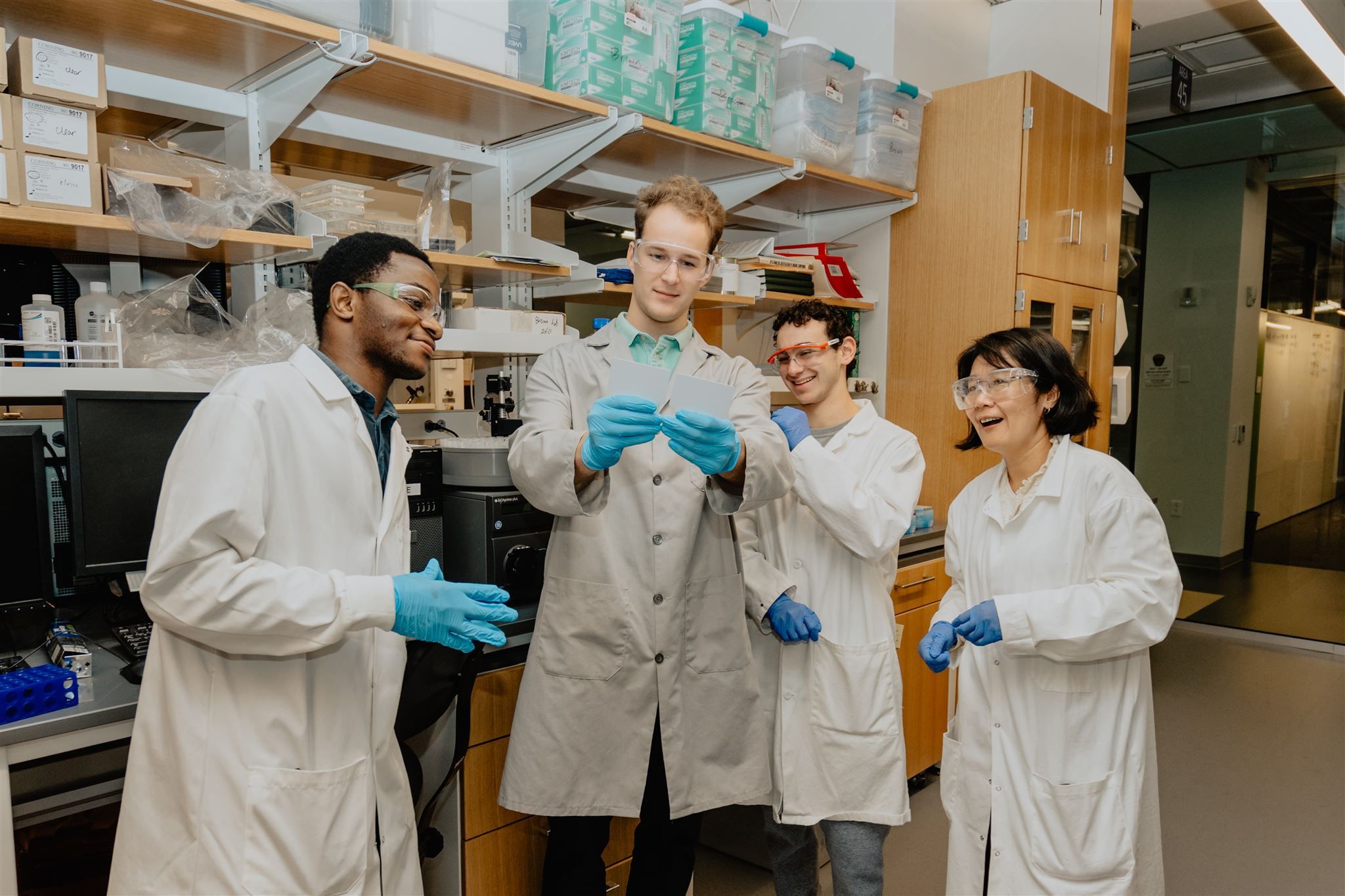

Cell Culture Lab: A one-of-the-kind on campus, fully loaded, access-controlled bio-safety level II laboratory dedicated to shared use for mammalian cell and bacteria culture.

-

Furnaces and Presses Lab: The process lab contains a variety of furnaces for heat treating purposes from simple box furnaces to a Solar Mentor vacuum furnace. In the process lab you can also find a table top casting unit and a rolling mill for materials processing needs.

-

Ceramics Processing Lab: The ceramics processing lab provides the means to chemically and mechanically prepare samples for further processing to using furnaces (controlled environment, tube and box furnaces), hot presses, spark plasma sintering machine, and uniaxial presses. Post-sintering tools (diamond saws, etc.) allow for sample preparation for further analysis.

-

Loewy Institute: Mechanical metallurgy/ deformation processing laboratory

-

Specimen Preparation Lab: The specimen prep labs at Lehigh contain everything you need to prepare your sample for characterization. Cutting, mounting, grinding, polishing, etching, and coating equipment and supplies are available for use.

-

Machine Shop: Multiple manual and CNC lathes, mills and other equipment needed to prototype parts. Student-user machine shops are also available providing more hands-on experiences.

Characterization

-

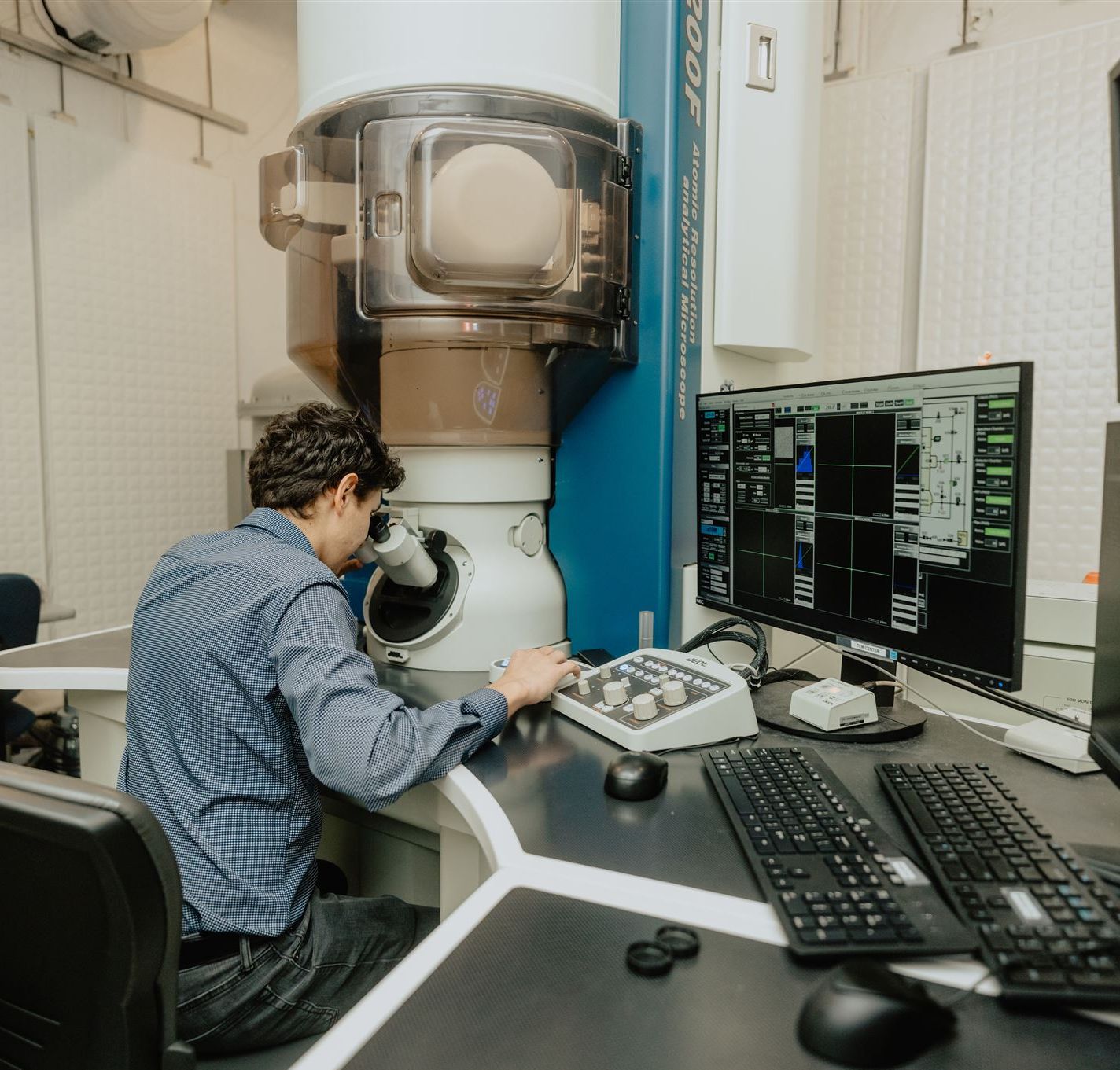

Electron Microscopy Lab: Lehigh maintains one of the most comprehensive electron microscopy facilities in the U.S., with a suite of 9 scanning, transmission and scanning/transmission (SEM, TEM & STEM) instruments. These are well suited for characterizing nanoscale structures and chemistry via an unparalleled range of imaging and analytical methods.

-

Optical Microscopy Lab: Lehigh's light optical microscopy suites offer a wide variety of imaging and characterization possibilities. Capabilities include stereoscopes and light microscopes with both reflected and transmitted modes, polarization, bright and dark field imaging, etc.

-

X-ray Diffration Lab: X-ray diffraction for powder, bulk, and thin film samples.

-

Surface Characterization Lab: Low energy ion scattering and x-ray photoelectron spectroscopy for composition and chemical analysis of surfaces.

-

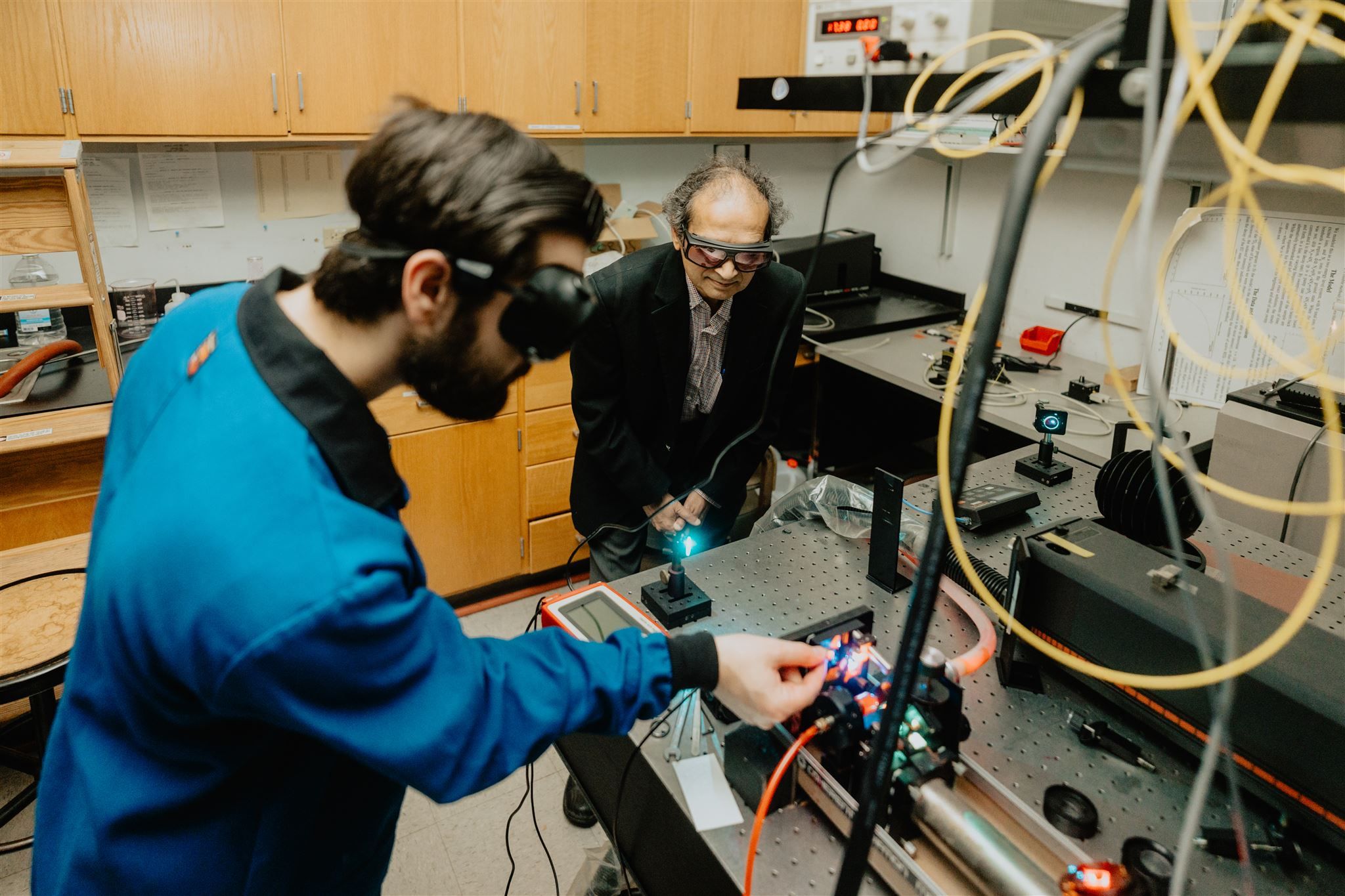

Device and Semiconductor Characterization: Beyond tools already available in the Surface Analysis Lab, more advanced spectroscopy and electronic measurements can be performed, including Hall measurements, photoluminescence mapping, etc. allowing for standard and advanced MEMS, high speed (bio)electronic and (bio)photonic device characterization.

-

Core facility at Biological Sciences: A wide array of state-of-the-art equipment to support ongoing research including centrifuges, flow cytometry, gel/blot imaging, spectroscopy (fluorescence, luminescence and UV-VIS), and tissue sectioning.

-

Health Research Hub: High-throughput SAXS and WAXS for analyzing isotropic, colloidal and biological samples (BioSAXS), optical coherence tomography.

-

Welding and Thermal Analysis: Full automated welding lab with GTAW, GMAW, SAW, and SMAW processes, thermal analysis lab with DTA/TGA, and Gleeble thermo-mechanical simulator

-

Mechanical Testing: An expansive array of mechanical testing equipment including tensile testers with controlled environments and high temperature capabilities, hardness indenters, thin film measurement systems, and Charpy tool.

-

Polymer Characterization: Extensive array of characterization tools needed when working with polymers including a rheometer, DSCs, TGA, DTAs, flow calorimetry, environmental chambers (thermal cycling, humidity, UV ozone), and scanning acoustic microscopes.

Computational/Digital Visualization

-

Visualization and Data Analysis Laboratory: A novel approach to enhancing human-computer interactions with associated algorithms (based on AI) and hardware to visualize scientific data using immersive methods, such as augmented reality, growing out of the Nano-Human Interfaces (NHI) Presidential Research Initiative. Provides remote access to cutting edge instruments for medical and materials imaging in the Center for Electron Microscopy and Analysis (CEMAS) at Ohio State, and in the adjacent electron microscopy laboratory at Lehigh.

-

Lehigh Computing Resources: Lehigh's HPC platform offers a variety of high-performance computing platforms and software for both research and teaching. Users may choose from a range of services depending upon their requirements and interests. Among these resources, Lehigh (LTS) manages a 55-node GPU-accelerated cluster that can be used by this program. The LTS Research Computing group also supports the use of national super-computing resources through the Extreme Science and Engineering Discovery Environment (XSEDE) Campus Champion program.