Everyone loves a hero. Or at least it seems that way. Marvel superhero films have grossed more than $29.8 billion worldwide, making the franchise the most popular of any ever created.

Professor Ricardo H.R. Castro has a theory about why the world can’t get enough of characters who can fly or shape-shift, have superhuman strength or telepathy, or can regenerate lost limbs or even manipulate reality itself.

“We love that connection with the impossible,” says Castro, who is chair of the Department of Materials Science and Engineering and a lifelong Marvel superfan. “I think we can use that connection to inspire remarkable creativity in our engineering students.”

He believes it so strongly, he created an undergraduate class, Engineering Superheroes, to do just that. The class is an extension of one he created while a professor at University of California, Davis, and it made its debut at Lehigh this spring. It combines lectures with demonstrations and labs to shed light on how materials give superheroes—like Thor, Captain America, and Ironman—their powers. The students then try to create their own (albeit less potent) versions of those hammers, shields, and battery packs.

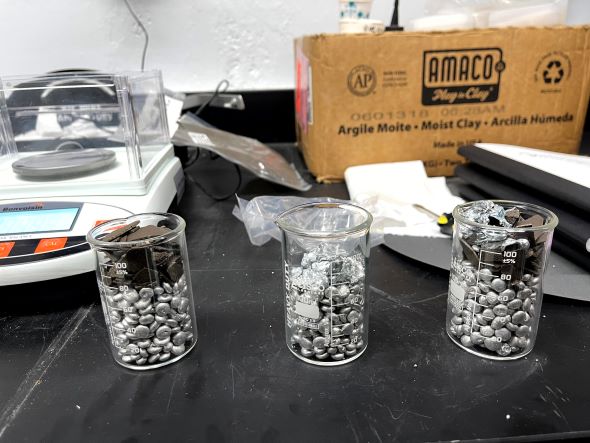

“For example, Thor’s hammer is made of a fantastic metal called uru that was forged in the heart of a dying star,” says Castro. “The metal doesn’t exist, of course, but we can talk about the concept behind it. Why does it have such a high melting point? How is that related to its strength? And then we talk about alloy design: What metals would you mix to increase the melting point to create material that would make for the ultimate hammer?”

In the lab, the students design their own alloys, cast their own hammers, and use an engineering tool called a Charpy test to assess the amount of energy required to break their creations.

“It’s fun, but it’s also a real engineering experience,” says Castro. “They learn valuable concepts and how to apply them, and then they get to leave class with something they built themselves.”

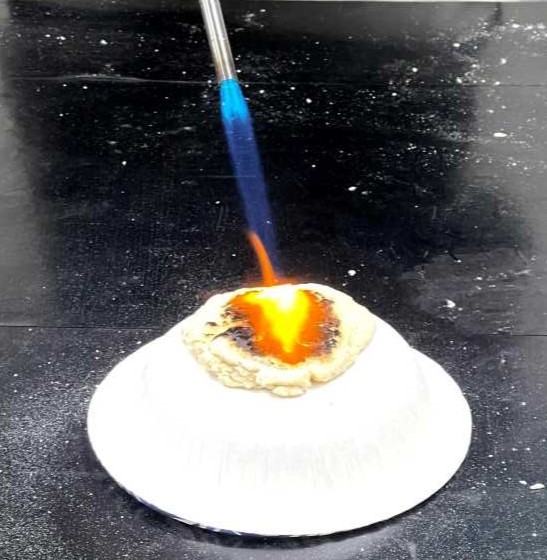

The class has also examined what makes Captain America’s only weapon—his Vibranium-metal alloy (note: not real) shield—so effective. Whatever form of evil it takes on (lasers, for example), the shield remains impenetrable. As a class, the students talk about what materials could make the shield such a good thermal insulator, and then together, they design a small one with a thin protective organic layer on the surface.

“Then we’ll go outside and hit the shield with a flame,” he says. “I’m always the one behind the shield, of course, but that’s another thing we talk a lot about—the safety concerns that are a big part of engineering.”

They also talk about scalability. Everything works on paper, says Castro, and while the thermal layer they design can protect the shield, he challenges the students to think of how that same design could be scaled up to protect buildings or aircraft.

“It becomes a very comprehensive education story,” he says.

It also gives students the opportunity to connect engineering concepts with exciting, if improbable, uses, and then create their own tangible versions of those materials. All of which helps prepare them for the harder, more math-intensive classes down the line, says Castro.

“This class gives them a visual foundation of applications, and the hands-on experience of doing things like developing an alloy,” he says. “And it builds their confidence for those harder courses.”

Engineering Superheroes culminates in a virtual group project where Castro asks the students to come up with a “superpower” material and an application for it. No idea is too strange, silly, or far-fetched. In fact, he encourages his students to return to the wonder and imagination they had as kids, when there were no limits to what they thought they could do.

He points to a project a previous group of students came up with: a cell phone for the blind, where the screen morphed into textures and images—in addition to braille characters—that represented what was being shown on the screen. All to enrich the mobile experience for the blind.

“The purpose of the project is to identify a problem and, as a group, explore their creativity and ask themselves, How can we solve this in the most fantastical way? And I think being in this universe of superheroes gives them the freedom to think in really far-out ways.”

And that’s because Thor and all the rest allow their fans to accept the impossible. Is it ridiculous that his hammer can resist blasts that can destroy planets? Sure. Does it make any sense that it can control the weather? Not at all. But the possibility of the impossible is a magical thing.

“The world of superheroes is ultimately a world of creativity, and it’s the same in engineering,” says Castro. “Inspiring our students to be their most creative selves could transform the entire industry.”

—Story by Christine Fennessy