It’s often the first thing we notice about a vehicle, and it reveals a lot: how new (or not) the vehicle is, how it’s been cared for, where it’s been driven.

“Consumers are extremely picky regarding the quality of the paint job on any car they purchase, new or old, and the 10- to 20-year appearance of a car depends on 10 to 20 critical minutes of application and drying,” says James Gilchrist, a professor of chemical and biomolecular engineering at Lehigh University’s P.C. Rossin College of Engineering and Applied Science.

Paint, however, is more complicated than you might think. If its formulation isn’t right, instabilities can form unsightly pockmarks. It’s also highly energy intensive to apply, accounting for 60 percent of the energy consumed by a single automotive plant, says Gilchrist. Manufacturers use robots to spray the paint, and that spraying takes place in rooms designed to contain and safely emit volatile organic compounds. When an application isn’t done correctly, the vehicle must be recoated and touched up—a process that can cost a single plant more than $10 million per year.

In November 2019, Gilchrist and his collaborators received a grant for a project that will essentially help industry get it right the first time.

The National Science Foundation’s Fluid Dynamics program awarded Gilchrist—who is working with collaborators at Case Western Reserve University (CWRU) and PPG—more than half a million dollars ($304,000 of which funds Gilchrist’s lab) in support of his Grant Opportunities for Academic Liaison with Industry (GOALI) proposal to better understand paint through kinematics and rheology (the study of how substances flow).

GOALI proposals address shared interests of academic researchers and industrial partners, seeking to advance scientific and engineering knowledge that could lead to technological breakthroughs relevant to industry needs. PPG is one of the largest global coating companies, with more than 47,000 employees and operations in over 70 countries.

“We’re trying to understand the fundamental drying process, and how these paints chemically and physically evolve while they’re drying,” Gilchrist says.

Gilchrist joined the project through CWRU assistant professor Chris Wirth and Reza Rock, PhD, principal investigator for PPG. Wirth conceived the idea in 2012 while working as a research chemist at PPG, but didn’t begin intense work on the idea until joining the faculty at CWRU.

“PPG provided financial support to my lab for two and a half years leading up to the NSF GOALI project,” says Wirth. “This early support from them was critical in showing our techniques were feasible in such complex systems and in helping this team identify the fundamental issues that needed to be solved for the full potential of our strategy to be realized.”

Rock leads the Coatings Insight Team at PPG’s Coatings Innovation Center, and his group will provide guidance and feedback to Gilchrist and Wirth. Specifically, how findings and results from their research can be connected to industrial impact and application. “We anticipate that this project will significantly advance our understanding of the complexities of coating application, drying, and curing behavior, through development and implementation of new characterization approaches,” says Rock.

Typically, vehicles are sprayed twice. A base coat bonds with the material of the car part, and while that layer is still wet, a top coat is added to give the car its finish. Together, the two layers provide the chemical and physical properties that both protect the car and make it look good.

“But you can imagine that when you do this, the second layer could displace the first, or mix with it, and you want two distinct layers,” Gilchrist says. “So what companies like PPG do is add rheological modifiers that allow the paint to act like a liquid while you’re spraying it, but once it hits the car and makes a thin film, it temporarily acts like a solid before the next layer is sprayed on.”

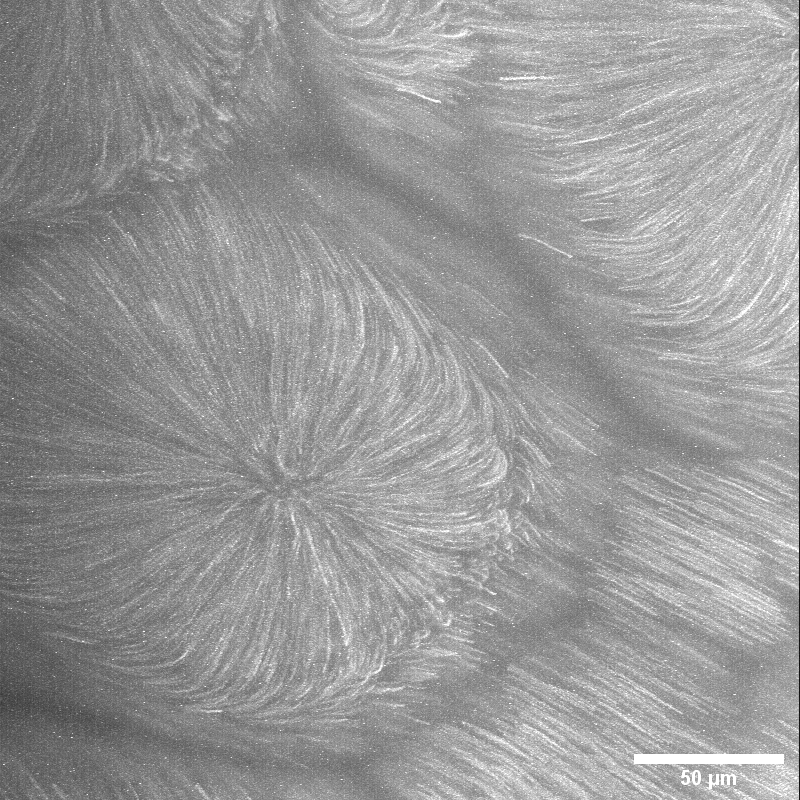

Gilchrist and his team are using microrheology to study the effect on the system of adding different rheological modifiers—particles with a range of geometric and surface properties. By putting fluorescent probes in the paint and tracking with a microscope how they move, the researchers can determine if a particular formulation is causing the paint to act like a solid or a liquid as it’s drying.

“It’s even more complex from the standpoint that the additives change the rheology of the materials, but then the rheology itself is evolving over time while it’s drying. It’s a very dynamic, complex process that needs more fundamental science.”

The goal, says Gilchrist, is to develop a testing method that can be used to both predict how a given formulation will behave, and quickly identify the problem if something goes wrong in the plant.

“If a company can predict a product’s performance ahead of time, they won’t have to paint a million cars before they find out something is wrong with it. They’ll know, ‘Okay, this formulation produces these properties and this type of paint job.’ The reverse of that is, if the paint does behave funny in the plant, they can take that batch and perform microrheology, and ask, ‘Did it behave the way it should based on the formulation? Was it formulated incorrectly? Did something else happen under the painting conditions?’ Developing a testing method will allow them to identify the problem quickly, and change the formulation appropriately.”

The idea of applying microrheology to automotive plants is new, and it has the potential to save millions of dollars in energy use and help companies get their products to market faster.

“These fundamental insights can be used to accelerate formulation efforts related to developing more energy-efficient coating systems that can cure at lower temperatures,” says Rock.

The project is also a perfect example of how partnerships are bridging the gap between needs and expertise.

“Industries just don’t have all the tools, capabilities, and bandwidth to be driving their technology 10 years from now, 20 years from now,” says Gilchrist. “And that’s where partnerships with universities are really important. They need a measurement to troubleshoot their process, and we’re going to develop a tool that will speed up their product development.”

—Christine Fennessy is staff writer for the P.C. Rossin College of Engineering and Applied Science.

About James Gilchrist

James Gilchrist is a professor of chemical and biomolecular engineering at Lehigh University’s P.C. Rossin College of Engineering and Applied Science. His research and scholarly activities are designed to impact both science and engineering through fundamental studies of particulate systems. From an engineering viewpoint, particle technology is ubiquitous, including pharmaceutical, chemical, agricultural, food, cosmetic, ceramic, electronic, and mining processes and in an uncountable number of natural processes including sediment transport in rivers, dune formation, and blood flow. An overarching objective of Gilchrist’s research is to develop a better understanding of these far-from-equilibrium particulate processes exhibiting complexity and self-organization.

Gilchrist manages the Laboratory for Particle Mixing and Self-Organization, where he and his team investigate phenomena ranging from the nano- to macro- scales, typically divided into colloidal and granular systems. Researchers in the lab identify prototypical complex systems for study and develop new experimental, computational, and analytical methods of investigation and analysis. Projects include suspension transport in chaotic flows, suspension rheology and microstructure, convective deposition, suspension dielectrophoresis, and granular dynamics in vibrated systems. Paired with this fundamental research is collaborative development of applications involving novel processes, materials, and devices such as microfluidic- and industrial-scale mixing and separation, light emitting diode and dye sensitized solar cell coating and internal structure fabrication, fabrication of BioMEMS sensor platforms, and dynamic powder density measurement for online process analysis. Much work has been performed in particle-laden coatings. The long-term goal of this work is to further fundamental understanding of suspensions and granular processes and to devise novel ways of controlling these systems.

Professor Gilchrist received his Bachelor of Science in chemical engineering from Washington University in St. Louis and his PhD from Northwestern University. Prior to joining Lehigh’s faculty in 2004, he was a postdoctoral research associate in the Department of Materials Science and Engineering at the University of Illinois. He held Lehigh’s P.C. Rossin Assistant Professorship from 2007-2010 and the Class of 1961 Associate Professorship from 2013-2015. He received the North American Mixing Forum Young Faculty Award in 2007. Gilchrist was a visiting professor in the Department of Chemical Engineering at the California Institute of Technology for the 2011-2012 academic year, and a Visiting Professorial Fellow at the University of New South Wales in 2016.