The addition of renewable energy into the electrical grid is forcing conventional power plants to adapt to new power generation realities.

“Fossil power plants used to generate power at maximum capacity all day long,” says Carlos Romero, director of Lehigh University’s Energy Research Center (ERC). “They were what we call base-loaded, and that’s the best operating point for the plant in terms of thermal efficiency. But now, with renewables like solar and wind on the grid, these conventional plants are required to operate on load-following mode and at extremely minimum loads. Because of the deviation of actual efficiency from the design value, fuel consumption increases, and there is a corresponding monetary loss during the operation of the power plant.”

An interdisciplinary team, promoted by Lehigh’s Institute for Cyber Physical Infrastructure and Energy (I-CPIE), is starting a project on thermal energy storage (TES) for applications in fossil-fired power plants.

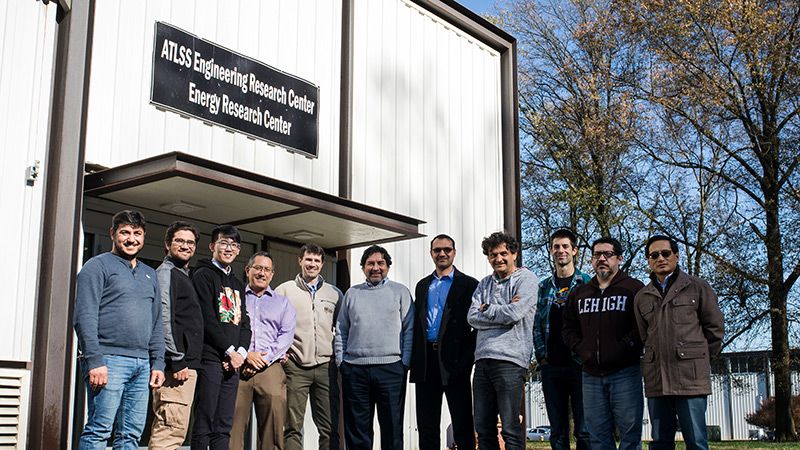

The team matches the ERC’s expertise in power generation and energy with appropriate expertise in civil engineering within Lehigh’s Advanced Technology for Large Structural Systems (ATLSS) Engineering Research Center. Both the ERC and ATLSS are affiliated with I-CPIE, which focuses on interdisciplinary team science around the demands and impacts of society’s reliance upon energy, communications, structural, and transportation systems. I-CPIE is one of three Interdisciplinary Research Institutes launched by the university in 2018.

The project includes partners from Advanced Cooling Technologies Inc., Dominion Energy (of Virginia), Slaw Precast (a concrete prefabrication company), Nycon (a steel fiber company) and Hanson Cement, and marks the start of a potentially productive collaboration between ERC and ATLSS. ATLSS and the ERC have also submitted proposals on novel concepts in zero energy building energy research.

The group recently received a three-year, $2 million grant from the Department of Energy (DOE) as part of its Transformative Power Generation Program. The program supports research that will improve advanced power technologies to enhance energy production and protect the environment. Lehigh’s group is one of 13 projects selected to receive a portion of $32 million in federal funding from the DOE’s Office of Fossil Energy and its National Energy Technology Laboratory (NETL).

Lehigh’s collaborative team, which also received a Collaborative Research Opportunity (CORE) Grant from the Office of the Vice President and Associate Provost for Research and Graduate Studies at Lehigh in this particular topic, includes Romero, Clay Naito (civil and environmental engineering), Sudhakar Neti (ERC, PI), Alp Oztekin (mechanical engineering and mechanics), Spencer Quiel (civil and environmental engineering), Muhannad Suleiman (civil and environmental engineering), Kemal Tuzla (chemical and biomolecular engineering), and Zheng Yao (ERC).

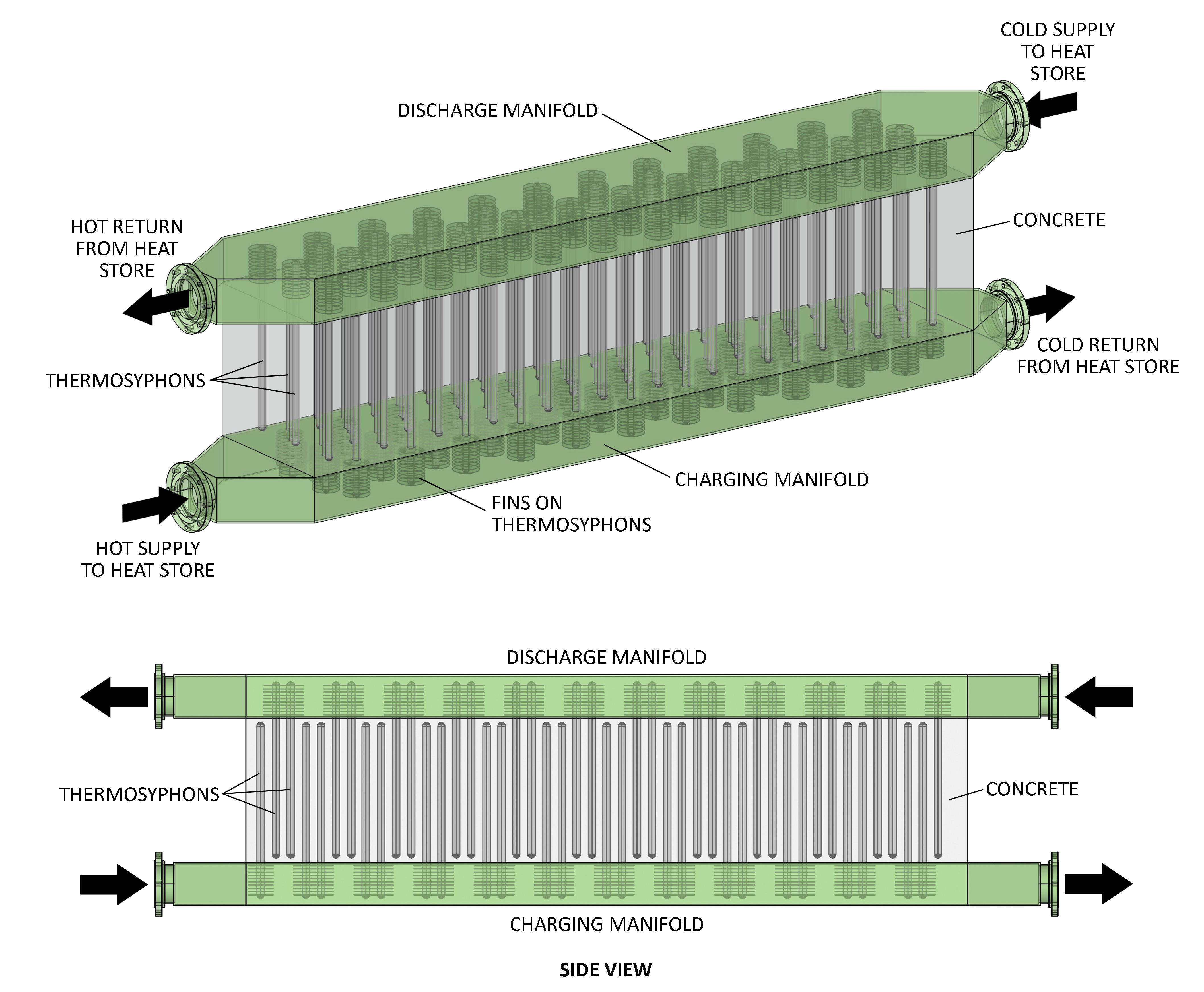

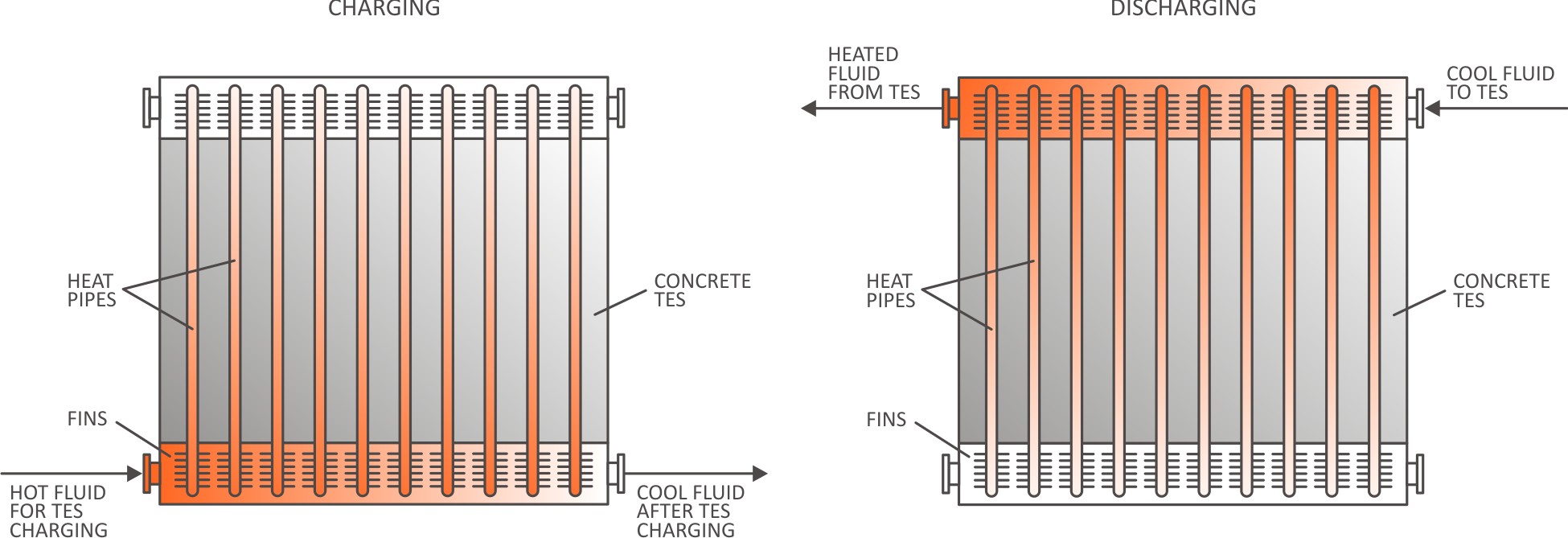

The Lehigh team will use the three-year grant to develop an optimized prototype of a novel TES concept, named Thermosiphon technology embedded into an optimized Cementitious Matrix for combined sensible/latent heat Thermal Energy Storage (TCM-TES). The concept utilizes engineered cementitious materials enhanced with thermosyphons, which would allow for combined sensible and latent heat storage.

The Lehigh team will use the three-year grant to develop an optimized prototype of a novel TES concept, named Thermosiphon technology embedded into an optimized Cementitious Matrix for combined sensible/latent heat Thermal Energy Storage (TCM-TES). The concept utilizes engineered cementitious materials enhanced with thermosyphons, which would allow for combined sensible and latent heat storage.

Sensible and latent heat are two ways to store energy. Another way is thermochemical energy storage (TCES). Available concepts for solid media storage include rocks and sand, steam accumulators, and two-tank sensible storage based on molten salts.

“Due to its dual use as a storage media and heat transfer fluid, the two-tank molten salt storage technology is the commercial standard for solar-based power plants with TES, working in the 300-500°C temperature range,” says Neti, who is an emeritus professor of mechanical engineering and mechanics in the P.C. Rossin College of Engineering and Applied Science and a senior research scientist with the Energy Research Center. “However, the thermal properties, energy density, and cost of molten salts systems warrant development of alternative, more cost-effective concepts to make TES more competitive for power plant applications, as well as industrial processes. The TCM-TES concept we are developing would also be applicable to concentrated solar power (CSP) plants.”

The TCM-TES project will involve design, engineering, optimization, and testing of the new concept at laboratory scale and prototype scale at a power plant.

“We’re going to put devices called thermosyphons into the concrete,” says Neti. “The fluid inside these devices very quickly changes phases and it is that ability to change phase that enables the heat to move so quickly into and out of the concrete block.”

Naito, a professor of civil and environmental engineering, adds: “Dissimilar thermal expansion between thermosyphons, which charge the media, and concrete can result in the formation of high tensile stress in the concrete near the interface, and the formation of global cracking of the system. We will be exploring compliant materials with high thermal conductivity, as well as steel reinforcement and proper distribution of fibers to minimize the size of cracking if incompatible expansions were to occur. This can be supplemented with pre-stressing methods in which the concrete is pre-compressed using embedded steel under tension. These approaches are regularly used to minimize crack sizes in concrete structures subjected to harsh environments.”

This project will ultimately aim to develop a TES prototype designed and built for up to 400°C operation, 100 kWhth, with 90 percent round-trip efficiency, and cost of at least $25/kWhth, while advancing the concept Technology Readiness Level (TRL) to a level of 5.