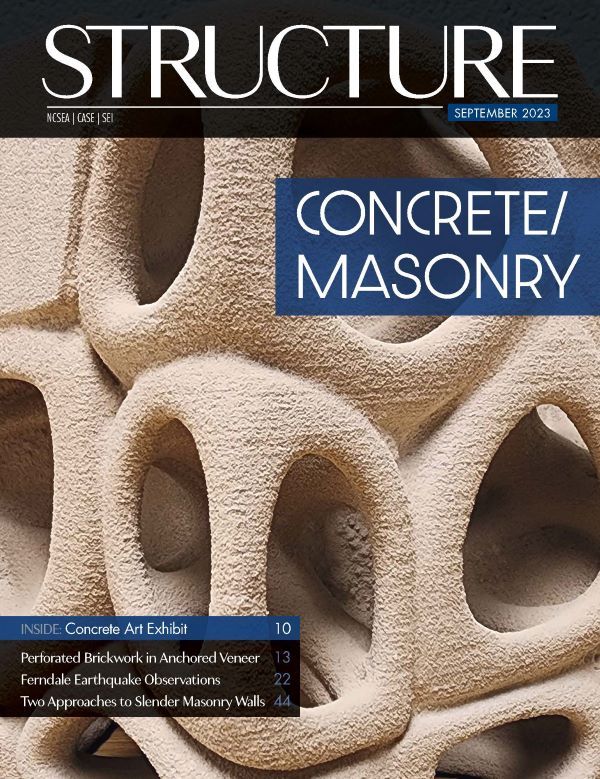

A closeup of an intricate concrete design made via an innovative 3D-printing method developed at Lehigh adorns the cover of the September 2023 issue of Structure magazine.

The magazine, which is a publication of the National Council of Structural Engineers Associations, includes a feature article describing the “particle bed 3D printing by selective binder activation” technique.

According to the article, in this additive manufacturing approach “a machine uses a roller to distribute uniformly onto a platform a thin layer of a specifically engineered dry powder, including cement, fine sand, and in some cases, additives. Then, an aqueous liquid is jetted onto the layer at selected locations to activate cement hydration. The process is repeated, layer after layer, until the structure is complete.”

Following a few finishing steps, the 3D-printed concrete object is cured in water for two to three weeks.

The technique can create more detailed concrete objects compared with existing 3D-printing methods, the researchers say, and it incorporates topology optimization, a computational approach to design that determines an optimal design for a structure, taking into account “desired objectives and constraints.”

The article was written by structural engineering PhD student Xingjian Wang on behalf of the project team, which includes Rossin College civil and environmental engineering faculty members Paolo Bocchini, John T. Fox, and Clay J. Naito; Nik Nikolov, an associate professor of architecture in Lehigh’s College of Arts and Sciences; and CEE doctoral student Urinrin Otite.

International cement producer Buzzi Unicem USA, which is headquartered in Pennsylvania’s Lehigh Valley, is also a collaborator. The research was partially supported by the PA Department of Community and Economic Development.

The technique is the subject of an exhibit, “The Future of 3D Printed Concrete,” currently on display at the National Museum of Industrial History, in Bethlehem, PA.

Read the full article, “A Museum Exhibit About The Future of Concrete,” in the September 2023 issue of Structure magazine.