It’s nice when you aim for a goal, and in the process of achieving it, nail another unexpected but significant target.

“We were just trying to generate a catalyst that would more efficiently make the product we desired,” says Christopher Kiely, the Harold B. Chambers Senior Professor of Materials Science and Engineering at Lehigh University’s P.C. Rossin College of Engineering and Applied Science. “Using less precious metal in the final catalyst material was a fortunate and unanticipated outcome.”

Kiely is part of an international team of researchers who recently published a paper in Nature Catalysis. The group developed a simple preparation method to control and manipulate the structures of supported platinum nanoparticles, which can be used as catalysts for the synthesis of functionalized anilines. Such compounds are used in the manufacture of products such as pharmaceuticals, fertilizers and dyes.

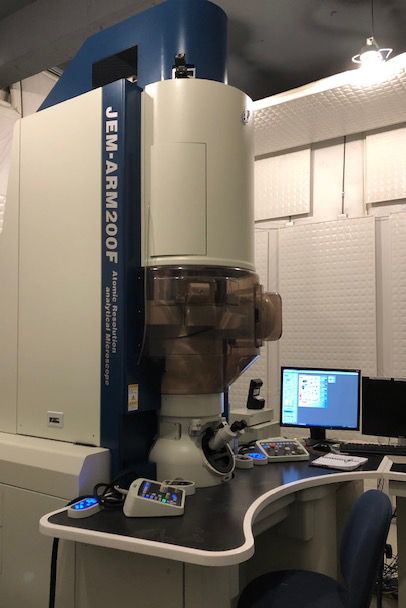

What made their study unusual, says Kiely, was the use of both analytical electron microscopy and advanced spectroscopic techniques available at a synchrotron source to fully characterize the catalyst materials.

“With the aberration corrected electron microscope at Lehigh, we could directly visualize these very tiny clusters of platinum,” he says. “We could see what size they were, how uniformly they were distributed on the titania support and how stable they were. The synchrotron studies allowed us to study the chemical state of the platinum and tell if it was bonded to oxygen. When you put the information gathered from these two techniques together, you gain a more comprehensive understanding of the catalyst nanostructure.”

Using the insight gained from these characterization studies, the team of researchers were able to fine tune the active sites (where the catalytic reaction occurs) in their platinum nanoparticles by various heat treatments and using very low platinum quantities to produce an optimized catalyst. In fact, they were able to reduce the amount of expensive platinum needed by a factor of ten as compared to the commercial version of the catalyst, while still retaining the same level of activity and completely eliminating any unwanted side products.

Kiely says that “The changes in synthesis procedure to obtain the optimized catalyst are relatively simple and cheap to implement, which should aid in their adoption by commercial catalyst manufacturers.”

The team was led by researchers from Cardiff University in the UK. Kiely’s former doctoral student Sultan M. Althahban ’19 PhD, who is now faculty at Jazan University in Saudi Arabia, performed the electron microscopy studies at Lehigh. Other contributors include Kiely’s former student and Cardiff University Research Fellow Qian He ’12 PhD (now faculty at the National University of Singapore) and researchers from Zhejiang University (China), University of Bologna (Italy), University of Glasgow, Rutherford Appleton Laboratory, University College London, and the University of Liverpool (UK).