Joshua Charles '11G, a Ph.D. student in mechanical engineering, has won a competitive award for his research into the use of phase change materials to help improve the efficiency of power plants and reduce the amount of pollutants they emit.

Charles, also a part-time research scientist at Lehigh’s Energy Research Center, has received a scholarship from the Air Pollution and Educational Research Grant Program (APERG), which is administered by the Mid-Atlantic States Section of the Air and Waste Management Association.

The scholarship is awarded to doctoral and post-doctoral students who are conducting research related to air pollution and air quality. The title of Charles’s project is “Low Temperature Phase Change Materials for Application Resulting in the Reduction of Airborne Pollutants from Fossil Power Plants.”

Phase change materials (PCMs) absorb thermal energy as latent heat at a relatively constant temperature as they melt. Then as they freeze, they release thermal energy, or heat. Charles is working with hydrated salts, which melt at room temperature and freeze as temperatures drop overnight.

The long-term goal of his research is to help improve the efficiency of power plants that use waterless air-cooled condensers (ACCs) to condense the steam from the turbines that generate electricity.

Thermoelectric power plants boil water to create the steam that spins the turbines to generate electricity. The steam is then cooled back into water and returns to the boiler. The cooling water used in this step represents the largest water withdrawal of the power plant.

Cooling is typically accomplished with cold water, but this poses challenges. Globally, freshwater supplies are dwindling, says Sudhakar Neti, professor emeritus of mechanical engineering and mechanics and one of Charles’s advisers. About two-fifths of fresh water In the United States, for example, is used to cool the steam from power plants.

Second, fresh water is in short supply in arid regions. Third, in “once through” power plants, cooling water is used once and then discharged back into the environment, typically into a river, where its heat can harm fish and other aquatic life.

ACCs use air to cool steam after it powers the turbines. They consume significantly less water than water-cooled power plants but they cool steam less efficiently, especially in regions with high ambient air temperatures. Because of this inefficiency, power plants employing ACCs require more fuel per kilowatt-hour (kWh) of power generated and are thus more expensive to operate.

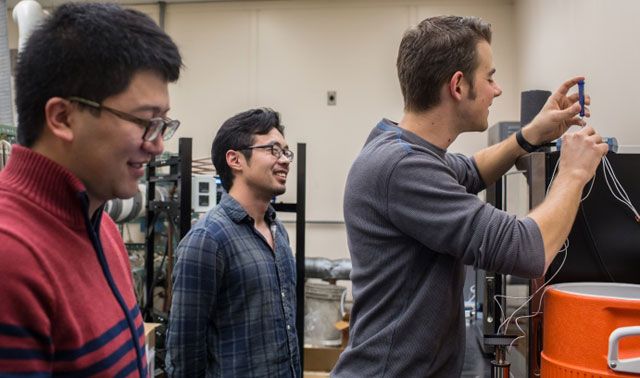

Charles, who earned his M.S. at Lehigh in mechanical engineering, is seeking to improve the cooling efficiency of ACCs by supplementing them with PCMs. In a lab in Lehigh’s Energy Research Center (ERC), he has built a cycling testing machine that tests 200 grams of hydrated salt, melting and refreezing the material once every two hours for 12 cycles per day. Over a nine-month period, the machine will simulate the effects of eight years of use of the material in a power plant.

Read the full story at the Lehigh University News Center.

-Kurt Pfitzer is Manager of Editorial Services with Lehigh University's Office of Communications and Public Affairs.