New findings in the process of glass transformation could lead to more energy-efficient manufacturing

Charles McLaren, a Ph.D. candidate in materials science and engineering at Lehigh, arrived last fall for a semester of research at the University of Marburg in Germany with his language skills lagging significantly behind his scientific prowess.

“It was my first trip to Germany, and I barely spoke a word of German,” he confessed.

With the help of his new German colleagues, he got past the point-and-eat phase of the international experience in no time. “The group members there were very welcoming. They showed me around and helped me learn enough vocabulary to order some food, at least.”

The main purpose of McLaren’s exchange study in Marburg was far from culinary, however. He was there to learn more about a complex process involving transformations in glass that occur under intense electrical and thermal conditions. New understanding of these mechanisms could lead the way to more energy-efficient glass manufacturing, and even glass supercapacitors that leapfrog the performance of batteries now used for electric cars and solar energy.

“This technology is relevant to companies seeking the next wave of portable, reliable energy,” said Himanshu Jain, the T. L. Diamond Distinguished Chair in materials science and engineering at Lehigh and director of its International Materials Institute for New Functionality in Glass.

“A breakthrough in the use of glass for power storage could unleash a torrent of innovation in the transportation and energy sectors, and even support efforts to curb global warming.”

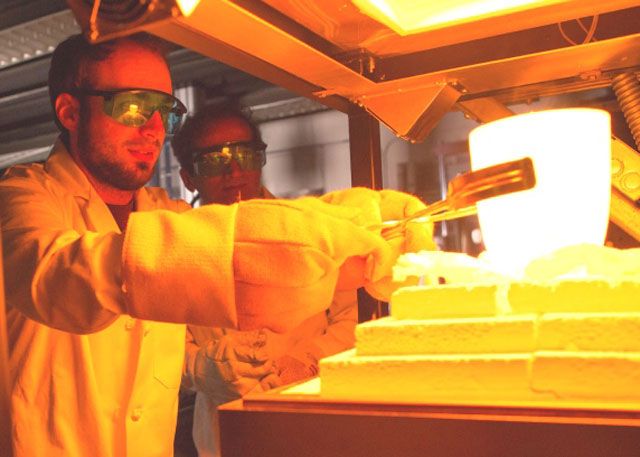

In his doctoral research, McLaren discovered that applying a direct current field across glass reduced its melting temperature. In lab experiments, he and Jain placed a block of glass between a cathode and anode, and then exerted steady pressure on the glass while gradually heating it. Together with colleagues at the University of Colorado, the Lehigh researchers reported their results last fall in Applied Physics Letters.

The implications for the finding were intriguing. In addition to making glass formulation possible at lower temperatures and reducing energy needs, designers using electrical current in glass manufacturing would have a tool to make precise manipulations not possible with heat alone.

“You could make a mask for the glass, for example, and apply an electrical field on a micron scale,” said Jain. “This would allow you to deform the glass with high precision, and soften it in a far more selective way than you could with heat, which gets distributed throughout the glass.”

Though McLaren and Jain had isolated the phenomenon and determined how to dial up the variables for optimal results, they did not yet fully understand the mechanisms behind it. McLaren and Jain had been following the work of Bernard Roling at the University of Marburg, who had discovered some remarkable characteristics of glass using electro-thermal poling, a technique that employs both temperature manipulation and electrical current to create a charge in normally inert glass. The process imparts useful optical and even bioactive qualities to glass.

“Working in Marburg also showed me how to interact with a completely different group of people," said McLaren. “You see differences in your own culture best when you have the chance to see other cultures close up. It’s always a fresh perspective.”

Read the full story at the Lehigh University News Center.

-Story by Chris Quirk, courtesy of Lehigh University's Office of Communications and Public Affairs.