Borides are compounds composed of boron and one other element. They are known for being extremely hard, and as such, researchers believed that mixing four or more metals in the boride system—to create what are known as high-entropy borides—would yield even harder materials. Such materials could have potential applications in both military and space aircraft.

“But mixing those metals didn’t improve hardness,” says Prince Sharma, a Lehigh mechanical engineering PhD student. “When we make high-entropy materials, we expect them to become 20 to 30 percent harder, but that wasn’t happening.”

Sharma recently published a paper in Chemistry of Materials that uncovered the reason why.

“We ran quantum mechanical calculations and did charge analysis, and we discovered that there was an electronic distortion in these multi-component borides that was affecting the hardness,” says Sharma. The team is currently working on how to overcome this distortion, and that work will be the subject of their next paper.

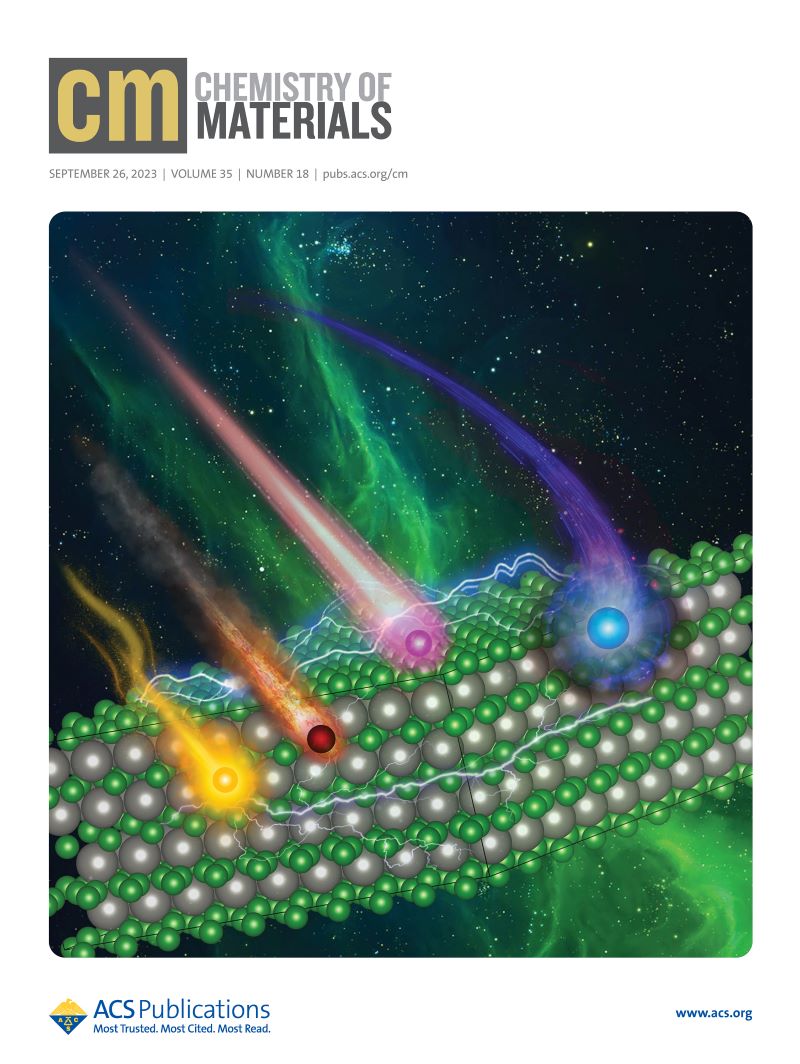

To further illustrate their research, Sharma designed a supplementary cover for the journal that depicts multi-component elements as colorful comets about to collide with a boride compound.

To further illustrate their research, Sharma designed a supplementary cover for the journal that depicts multi-component elements as colorful comets about to collide with a boride compound.

It was Sharma’s first attempt at rendering such a visual, and while it took him a few days, it was a unique experience, and one of many since starting his graduate studies at Lehigh.

As a master’s student at the Indian Institute of Technology Hyderabad in India, Sharma knew he wanted to pursue materials physics research, and eventually become a scientist or professor.

“Before coming to Lehigh, I was a complete experimentalist,” says Sharma, explaining that he has now "learned how to do theoretical calculations based on density functional theory. This has really given me an edge in job interviews because I can now do both experimental and theoretical work.”

Sharma is also a member of Lehigh’s Pasteur Partners PhD (P3) program, which supports doctoral students pursuing solutions to industry-specific problems. As part of the program, Sharma is co-advised by William Tucker of NASA's Ames Research Center in California. Last summer, Sharma did an internship at the center.

“I had the opportunity to work directly with Dr. Tucker on tungsten alloys, and that gave me insight into how scientists work in industry as opposed to in academia where the goals and deadlines are different,” he says. “Things move faster in industry, and I was responsible for completing my work over the course of that internship.”

He says the skills he’s developed and the connections he’s made at Lehigh are setting him up to make a real impact on the field.

“Our goal as researchers is to find better materials,” he says. “If we can develop very high temperature resistant materials, we can increase the efficiency of engines and that saves fuel. If we can find alternatives to elements that are expensive and aren’t found here in the U.S., that benefits agencies like NASA. That’s what motivates me. Developing new and better materials that can benefit us all and improve life for everyone.”