Robust engineering systems manage uncertainty in an infrastructure and respond effectively to emergencies and interruptions. The systems developed by Lehigh engineers run the gamut of scale, from micro-devices to large-scale structures to complex computing architectures. This section of Resolve looks at four of these systems.

Bridge safety, no strings attached

AN EARTHQUAKE STRIKES A LARGE CITY, wrecking roads and bridges, stranding rush-hour commuters, trapping office workers inside high-rise buildings.

As director of the city’s transportation authority, you have minutes to make a momentous decision. What is the safest, fastest route that rescue teams can take to travel to hard-hit areas of the city? Which bridges, even if damaged, can still support traffic loads?

The answers, says Yunfeng Zhang, can be provided by sensors – networks of tiny sensors embedded in computer chips that are attached to a bridge to monitor its structural integrity and performance.

Sensors deployed strategically on a bridge, says Zhang, assistant professor of civil and environmental engineering, can provide a high-resolution, multidimensional picture of a critical part of the structure, giving engineers vital information about the bridge’s performance and, in the aftermath of a catastrophe, its reliability.

To be useful in the event of an earthquake or other emergency, says Zhang, sensors must be able to transmit data in real time, virtually without delay, to the processing centers where data is interpreted.

Wired sensors can transmit data in real time, but they have limitations, says Zhang. Installing and maintaining the wires is costly and labor-intensive. Wires degrade over time and are prone to interference from electromagnetic signals. And wires occasionally give off faulty signals.

Zhang this year received a five-year NSF CAREER Award to develop wireless sensor networks for bridges and other structures and thus improve the transmission, storage and retrieval of sensor data. The project is titled “Integrated Research and Education in Smart Sensing and Intelligent Structures Technology.”

Wireless sensor networks, which are relatively new, avoid many of the problems that plague wired sensors. But they face obstacles. The relatively narrow communication bandwidth available for civil-engineering wireless sensors can reduce download rates to 1 kilobyte per second, not nearly fast enough to crunch the enormous amounts of data generated by a bridge in operation.

To overcome this limitation and improve data transmission and management, Zhang is developing high-performance datacompression algorithms for structural monitoring. His algorithms incorporate structural system information to remove redundancies and maximize the data’s usefulness. Zhang also uses data-mining techniques to more efficiently extract key information from data.

“Using the data-compression algorithm I’m developing,” he says, “we can minimize data-downloading time and download data in real time and evaluate it in a near real-time basis.”

Zhang’s research draws on computer science, information technology and electrical engineering, as well as structural engineering.

As part of his NSF project, Zhang plans to implement a wireless sensor network on a cablestayed suspension bridge in eastern China to monitor its structural health and operating condition. The bridge, built in 2000, was accidentally damaged during construction, and its actual operating condition is thus different from its design condition. The bridge was repaired and is operating, says Zhang, but aggressive monitoring is needed to ensure that it can continue to be safely used by traffic.

Using wireless sensor networks that he will help develop, Zhang and Chinese engineers are planning to conduct a full-scale validation test on the Chinese bridge in 2009.

Zhang says the data he collects from testing the Chinese bridge will also be useful for bridge operators in the U.S., where cablestayed bridges have only recently come into use and have not yet generated a large body of data.

As part of his NSF award, Zhang is incorporating his research into his classes. Last spring, Zhang taught an upper-level undergraduate course in smart structure technology that he first taught as a graduate course in 2004.

In the course, students constructed a Japanese pagoda and attempted to shed light on an ancient mystery – why, in earthquake plagued Japan, the wooden temples have for centuries withstood seismic forces much better than any other type of structure.

Zhang believes the smart structure technology course is the first civil engineering course in the U.S. to integrate sensors, communications, data-mining, information technology, structural engineering and structural health monitoring. Twelve senior civil engineering majors and five grad students enrolled in the course.

“I want to educate the next generation of engineers about an exciting technology that has broad future applications,” says Zhang. “Smart structure technology is only in its developmental stages, but as educators, we need to plan ahead so that when this technology is available in 10 years, our graduates will know how to utilize it.”

Image fusion is a lifesaver

AS A CAR PULLS UP TO A CHECKPOINT, soldiers scan driver and passengers, wondering if one of them is hiding a gun. As VIPs line up for a reception with the President, security guards look each person up and down, alert to any clue of malicious intent.

Rick Blum, the Robert W. Wieseman Chair in Electrical Engineering, hopes to equip these soldiers and security guards with a device that can save a few potentially lifesaving seconds in the search for concealed weapons.

Blum and his students have developed algorithms through which image fusion is accomplished in the wavelet transform domain. Their Portable Multi-Sensor Imaging Fusion System (PMSIFS) combines a photo taken by an optical camera with a photo of the same subject taken by a millimeterwave camera (MMW). The composite photo exposes much more than either photo reveals by itself.

Blum illustrates this application of “image fusion” with a set of three photos, arranged side by side, each showing the same shot of the same three men. The left image, taken with an optical camera, shows the men’s faces and clothing. The center image, taken with an MMW camera, shows neither physical features nor clothing, but reveals that the man on the right has a gun underneath his sweater.

On the right is the fused image, which police and military personnel are seeking. It shows enough of the men’s clothing and features to tell them apart, and it also reveals the unmistakable outline of a gun under the third man’s sweater.

The PMSIFS causes no physical harm to a person and can obtain a photo without a person’s knowledge.

Blum, a fellow of IEEE, has been working on image fusion for more than 15 years. His research has been supported by NSF, the Commonwealth of Pennsylvania, AT&T, the U.S. Army Research Office, the Office of Naval Research and the Air Force Office of Scientific Research.

Last year, Blum licensed his technology to SuperVision Technologies Inc. with help from a grant from Pennsylvania’s new Keystone Innovation Zone program.

Taking the bite out of earthquakes

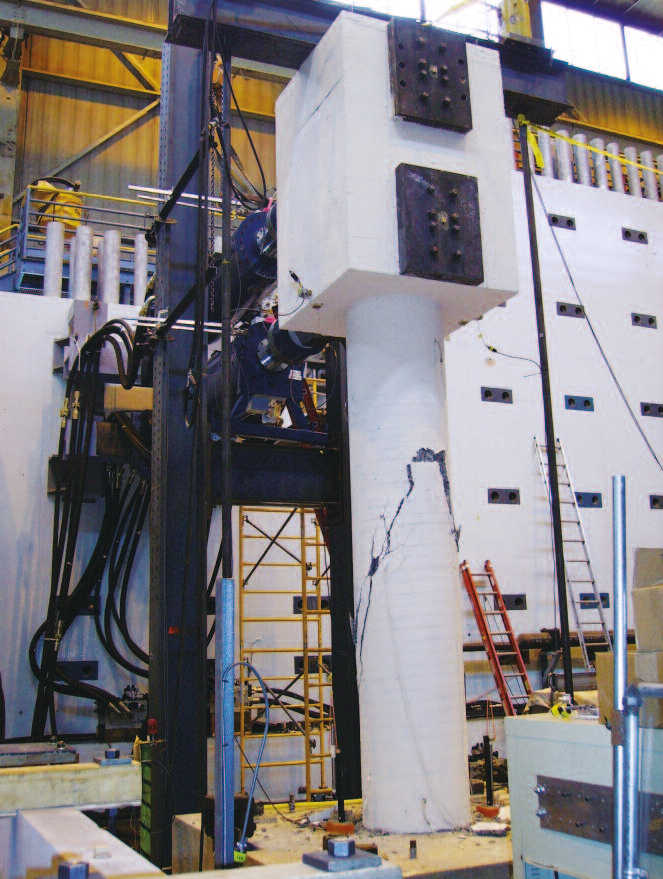

ENGINEERS AT LEHIGH’S ATLSS (Advanced Technology for Large Structural Systems) Research Center are leading a national effort to design and test buildings that can survive an earthquake with little or no damage.

In the past 60 years, says ATLSS director Richard Sause, engineers have learned how to build structures that protect occupants and minimize loss of life from earthquakes.

Now engineers are aiming to reduce the property damage and structural “down time” caused by seismic events.

“The building design profession has progressed from the point of accepting building damage in earthquakes, as long as injuries and loss of life are minimized, to the point of seeking significantly reduced damage,” says Sause.

“Our research is aiming toward a future where, if you look at a steel-frame building before and after an earthquake, you will see no significant difference.

Much of Lehigh’s earthquake-engineering research is funded by NSF through a research program using the George E. Brown Jr. Network for Earthquake Engineering Simulation (NEES), a consortium of 15 universities that includes Lehigh, the University of Illinois, Berkeley and UCLA.

Lehigh’s experiments are performed at the ATLSS Center’s Real-Time Multi-Directional Testing Facility (RTMD), one of the largest of its kind in the world, which subjects structures to loads and loading rates similar to what they would sustain during earthquakes of the largest magnitudes.

Lehigh is using NEES research funding to develop a variety of systems to enable structures to survive earthquakes. These include braced frames and viscoelastic dampers that absorb seismic forces, columns and beams that bend without breaking while retaining their original position and strength, and steel frames that “self-center” after an earthquake.

Many of these systems direct seismic forces to structural elements that can be replaced quickly and at little cost after an earthquake.

To develop the self-centering frames, ATLSS has received a $2-million grant from NSF and is collaborating with researchers from Princeton, Purdue and the National Center for Research in Earthquake Engineering in Taiwan. The project involves numerical simulations, lab experiments and the use of advanced materials, information technology and advanced sensors. The RTMD facility is equipped with MEMS-based accelerometers, piezoelectric transducers and fiber-optic strain gages.

Lehigh and other members of NEES are linked by Internet2, which enables universities to share data from experiments in real time and allows off-site researchers to interact, again in real time, with any of the networked sites.

Earlier this year, an experiment was conducted simultaneously at Lehigh, Illinois and Rensselaer Polytechnic Institute. Researchers simulated the effect of earthquakes on a freeway bridge structure, including several columns and the soil foundation. The columns were replicas of structures that were damaged during the 1994 Los Angeles earthquake.

The novel experiment, called a distributed hybrid test, was conducted to obtain an integrated picture of what happened systemically to the bridge, soil foundation and columns during the earthquake.

Until now, says Jim Ricles, director of Lehigh’s RTMD facility, earthquake engineering experiments have focused on single structural members as opposed to entire systems.

“Before, one isolated specimen was tested without integrating the data to the overall bridge structure. But if you test only one member, you don’t know how the rest of the structure will react.

“After we prove the worth and accuracy of distributed hybrid testing, we can use it to demonstrate alternative types of constructions and renovations. It will be a tool to demonstrate as realistically and accurately as possible the real-time performance of a structure during an earthquake.”

The RTMD facility has five 20-foot-long, torpedo-shaped actuators, which can impose 500,000 pounds of force on structures from a variety of angles at the rate of 1 meter per second. The actuators are the largest of their kind for structural testing. An advanced high-speed data acquisition, coupled with sensors and an eight-channel digital control system, enables the RTMD facility to be operated remotely.

Stochastic optimization the best bet

INVESTORS PREDICTING THE STOCK MARKET, farmers fretting over the weather, security officials anticipating a terrorist attack – the amount of uncertainty in the world can seem daunting.

Not to Jeff Linderoth.

Linderoth, assistant professor of industrial and systems engineering, marshals the world’s most powerful computers to tackle problems with millions of variables and possible outcomes.

Last year he received an Early Career Award from the U.S. Department of Energy (DOE) to solve large-scale numerical optimization problems characterized by high levels of uncertainty.

Linderoth tackles these “stochastic optimization” problems by developing software programs that use computational grids – groups and networks of computers whose collective capacities are harnessed to solve large-scale problems that would overwhelm a single computer.

Stochastic optimization problems require engineers to take into account two classes of variables, says Linderoth. Decision variables can be controlled. Random variables cannot.

One example of a stochastic optimization problem, says Linderoth, is the effort by the federal government to intercept illegal drugs flowing into the U.S.

“The government has a fixed budget to make it more difficult for drug smugglers to travel through the network, or border,” says Linderoth. “The uncertainty comes into play when, even if we choose to beef up a part of the network by installing sensors, we don’t know if the sensors will detect the drugs. The goal is to design a system that is robust with respect to these failures and will, in the long run, catch as many smugglers as possible.”

Linderoth will also help DOE with mixed-integer nonlinear programming problems (nonconvex optimization), which involve discrete, yes-or-no types of decisions as well as nonlinear elements that have a continuum of random values.

The design and installation of a gas pipeline network, says Linderoth, requires engineers to make both types of decisions. The location of pipes and compressors requires discrete decisions, while calculating the optimal flow of natural gas is a nonlinear problem.

All the software Linderoth develops will be made available via the Network-Enabled Optimization System (NEOS), a server established 10 years ago to help engineers, scientists, students and businesspeople solve optimization problems remotely over the Internet.

Linderoth was a member of the Argonne and University of Iowa team that solved the nug30 Quadratic Assignment Problem, a complex facility-location problem that had been unsolved for 30 years. The computation took one week of calendar time and 11 years of CPU time, as 653 machines participated.