In the ramp-up to more widespread renewable energy use, Thermal Energy Storage (TES) has become one of the options for enabling power grids to respond to variable supply and demand conditions. According to the latest report from the U.S. Department of Energy (DOE), Pathways to Commercial Liftoff for Long Duration Energy Storage (LDES), “the U.S. grid may need 225-460 GW of LDES capacity for power market application for a net zero economy by 2060, representing $330B in cumulative capital. TES was identified as a technology capable of providing intraday, inter-day (10-36 hours) and multi-day/week (36-100 hours) power shifting capabilities.

TES systems are like batteries that use temperature shifts to store energy for later use or for use at another location. Such systems capture energy in different ways, and the most commonly used techniques are based on latent and sensible heat transfer. The latent heat method involves using the amount of thermal energy needed for a phase change―which is a change in physical state, such as from solid to liquid, or liquid to gas―without altering a material’s temperature. Sensible heat storage uses the thermal energy provided to raise the temperature of a material without causing any phase transitions.

TES systems are like batteries that use temperature shifts to store energy for later use or for use at another location. Such systems capture energy in different ways, and the most commonly used techniques are based on latent and sensible heat transfer. The latent heat method involves using the amount of thermal energy needed for a phase change―which is a change in physical state, such as from solid to liquid, or liquid to gas―without altering a material’s temperature. Sensible heat storage uses the thermal energy provided to raise the temperature of a material without causing any phase transitions.

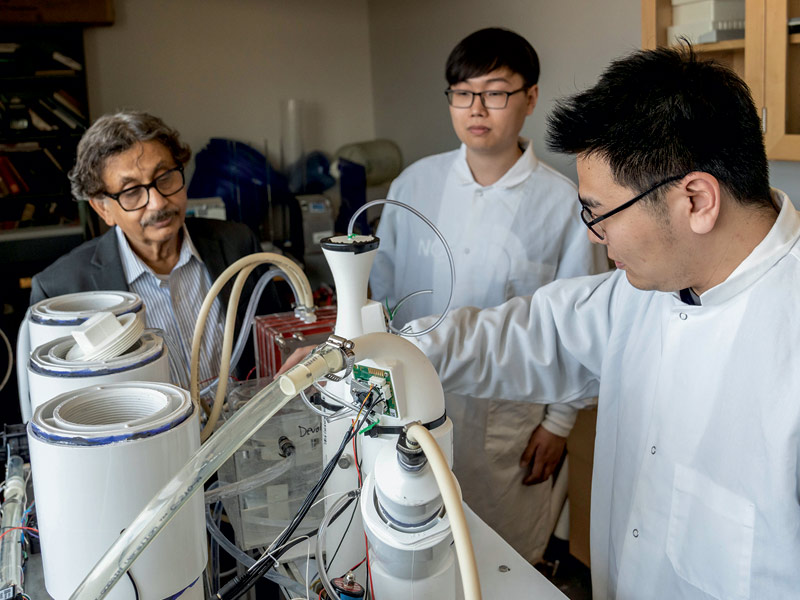

Now, Lehigh researchers, with support from the U.S. DOE, have developed a new thermal energy storage system, the Lehigh Thermal Battery, which combines the best of both techniques. The technology consists of engineered cementitious materials and thermosiphons in a combination that enables fast and efficient thermal performance at low cost. The technology is capable of operating with heat or electricity as the charging energy input. The team has announced that, after three years of research and development, the technology is scalable and prototype-ready.

The project is a collaboration between Lehigh’s Energy Research Center, Lehigh’s Advanced Technology for Large Structural Systems (ATLSS) Engineering Research Center and Advanced Cooling Technologies.

“The concrete plus thermosiphon concept is unique and new among utility-scale thermal energy storage concepts,” says Carlos Romero, co-principal investigator on the project and director of the Energy Research Center at Lehigh. “The technology offers the potential for adaptation over a broad range of temperatures, and heat transfer media and operating conditions. This makes it suitable for decarbonization opportunities in industry, flexibilization of conventional power plants, and advancements and penetration of concentrated solar power.”

“The Lehigh Thermal Battery technology is innovative because it is modular, designed for independent energy input/output streams during charging/discharging which is feasible with the help of the thermosyphons[CER3] , and the two-phase change process inside the thermosyphon tubes allows rapid isothermal heat transfer to/from the storage media at very high heat transfer coefficients and heat rates,” says Co-Principal Investigator Sudhakar Neti, professor emeritus in the Department of Mechanics and Mechanical Engineering at Lehigh.

The project has just completed a three-year schedule, which included research and development of system components, system design and integration, and integrated system testing at 3, 10 and 150 kWhthermal in a relevant environment. The 3-kWhthermal system, consisting of an electrically charged design, was tested at Dominion Energy’s Mount Storm, WV Power Plant, achieving repeatable electrical-to-heat round-trip efficiencies in the mid-70%.

A 150-kWhthermal prototype built at the Energy Research Center is a fully instrumented 5ft ø x 15ft tall structure containing 22 finned thermosyphons. The 150-kWhthermal prototype has been tested extensively using compressed air at 500°C, producing an energy-to-energy charge/discharge, round trip efficiency of the solid media at 94.8%, uniform temperature distribution in the solid media during charging, and consistent cyclic repeatability. Maximum energy density achieved was 144 kWhthermal/m3, with the capacity of 75% thermal load discharge in 1.5 hrs.

In addition to Romero and Neti, team members include: Clay Naito, Spencer Quiel and Muhannad Suleiman, faculty members in the Department of Civil and Environmental Engineering; Zheng Yao, Research Scientist at Lehigh’s Energy Research Center; and, from Advanced Cooling Technologies, a thermal management solutions company in Lancaster, Pennsylvania: Chien-Hua Chen, Devon Jensen, Yue Xiao, and Daksh Adhikari. Additionally, Lehigh graduate students Ahmed Abdulridha, Julio Bravo, Dominic Matrone and Shuoyu Arnold Wang were involved in the project.

“Lehigh’s Thermal Battery design physically separates the flows of energy into and out of the system,” says Naito. “Charging takes place by allowing a heat transfer fluid or electrical energy at a bottom plenum to activate the evaporator-charging section of the thermosyphons. A two-phase fluid inside the thermosyphons allows for rapid, uniform, and isothermal distribution of heat into the cementitious storage media.”

“Lehigh’s Thermal Battery design physically separates the flows of energy into and out of the system,” says Naito. “Charging takes place by allowing a heat transfer fluid or electrical energy at a bottom plenum to activate the evaporator-charging section of the thermosyphons. A two-phase fluid inside the thermosyphons allows for rapid, uniform, and isothermal distribution of heat into the cementitious storage media.”

“The energy storage solid media has been engineered to operate under heavy cycling duty by using a special concrete formulation which maximizes media heat capacity and thermal conductivity, while maintaining adequate mechanical strength,” note Naito and Suleiman.

In addition, the thermosyphon design has been optimized for dual (sliding evaporator/condenser sections) operation enabling the same device for the charging as well as discharging of the Lehigh Thermal Battery. This concept can be engineered to match the energy input and operational range of the sensible heat media. On the discharge side of the cycle, the sensible heat media acts as the evaporator, discharging and delivering energy through the thermosyphons. Additionally, “the concept is being expanded to operate at temperatures up to 800°C by reformulation of the solid storage media and the thermosiphon fluid,” says Quiel.

The research team working on the technology is also exploring different applications for utilization of this TES technology for applications for decarbonization of energy-intensive industries such as food, paper, chemicals, cement, steel; for flexibilization of fossil power plants and cost-efficient operation of carbon capture systems – e.g., (1) incorporation of the technology to avoid quenching of flue gas in single cycle gas turbines before entering the selective catalytic reduction (SCR) device for NOx emissions control, and (2) optimization of heat supply to the amine-based carbon capture regeneration process to mitigate its impact on unit efficiency and maximum capacity; (3) to support implementation of concentrated solar power (CSP) plants with energy storage, including (4) future sCO2-based Rankine cycles; and for (5) integration of TES in a scheme that includes Stirling heat pumps and Stirling/Ranking cycles for DC-to-DC storage of renewable electricity. Current estimates by the Lehigh team anticipate DC-to-DC round trip efficiencies in the 50% range for such system arrangements.

“Another opportunity for the Lehigh Thermal Battery to play an important role in the decarbonization effort is the integration of thermal energy storage in a system that includes heat pumps and Organic Rankine Cycles, working with surplus renewable electricity,” adds Neti.