The smaller the crystals, the bigger the possibilities.

So goes one of the mottos of Fadi Abdeljawad, an associate professor of materials science and engineering at Lehigh University. Abdeljawad joined the P.C. Rossin College of Engineering and Applied Science in August 2023 and has several research initiatives underway to develop theoretical and computational models that explain how materials behave at near atomic scale resolution.

“Materials properties that we experience in our daily lives are driven by features at the nano and even at the atomic scale,” says Abdeljawad. “Understanding how these features form or evolve will allow us to create novel materials with exciting properties for applications such as new energy technologies, lighter and stronger structures, and miniaturized devices.”

The first project is a three-year effort, funded by the Department of Defense and led by Professor Shen Dillon ’02 ’07 PhD at the University of California at Irvine, that will examine how interfaces in nanoparticles evolve under extreme environments, such high temperatures and mechanical loads, with direct applications to additive manufacturing, or 3D printing. Abdeljawad will perform computational studies employing atomistic simulations, and his predictions will be experimentally tested by Dillon, a materials science and engineering alum who was advised by Professor Martin P. Harmer during his time at Lehigh.

“This synergistic approach will allow us to cross validate our modeling results,” says Abdeljawad. “It’s an exciting collaboration because we’re performing both the modeling and the experimentation at the atomic scale.”

Their approach is also novel in that it approaches materials synthesis and processing from the bottom up.

“We’re seeking to answer scientific questions that will ultimately enable us to control and tailor properties at the nanoscale,” he says, “so essentially, building materials one atom at a time.”

Such materials could play a future role in miniaturized devices, or in the aerospace industry, where materials have to withstand extreme environments.

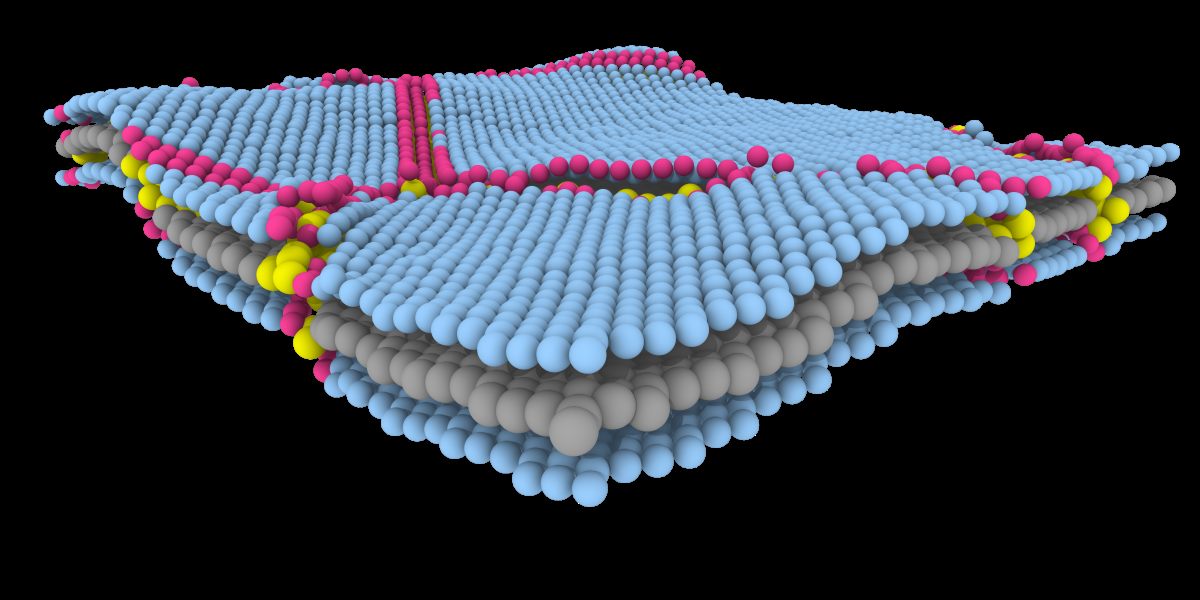

His second project is a three-year collaboration with the Department of Energy’s Sandia National Laboratories that combines modeling and experimentation to examine the properties of two-dimensional (2D) materials.

Over the past decade, researchers have synthesized these 2D materials, which extend in two dimensions, but the scale in the third dimension is smaller by orders of magnitude—similar to a sheet of paper. For 2D materials, thickness is measured in nanometers.

“If I take a piece of human hair and slice it along its length about ten thousand times, each one of those slices will be about 5 nanometers in thickness,” says Abdeljawad. “That’s how thick these 2D nanomaterials are.”

The materials have highly interesting engineering and functional properties. For example, they can be tailored for tribological applications. They have compelling transport and mechanical properties, too.

These properties are believed to come from defects, or imperfections, within what’s known as grain boundaries—internal interfaces where crystals within the 2D material meet.

“And it turns out, almost all these interesting properties are influenced by these interfaces,” he says.

“We typically think of defects as undesired features,” says Abdeljawad. “But in this case, we believe the defects are what gives the material these interesting properties. So instead of considering them as a detriment, we think of them as a design tool. If we can better understand these interfaces, these defects, we can tailor them to create materials with exciting properties.”

Abdeljawad brings his third project to Lehigh from his former faculty position at Clemson University. The research, supported by the National Science Foundation’s Condensed Matter and Materials Theory program, focuses on a class of nanomaterials called nano-crystalline high-entropy alloys (materials made of near equal amounts of various elements).

“Classically, this isn’t how we make materials,” he says. “We usually have a base, or majority element, and then add smaller amounts of other elements to get the properties we want. So, for example, nickel alloys and titanium alloys are used in a wide range of aerospace applications. In this project, the class of materials has no base element. And they happen to exhibit interesting mechanical properties.”

The nano-crystalline materials are also extremely strong.

“The smaller their crystals, the stronger these materials are, because of the increased density of internal interfaces,” he says.

Abdeljawad will use theoretical and computational modeling to study the chemistry of these interfaces and gain a greater understanding of how they behave under elevated temperatures.

“When we mix various chemical elements, does that make the material stronger or weaker?” he says. “Is it stable or less stable at elevated temperatures?”

The potential for these alloys is vast. Lighter, stronger materials could help improve sustainability within the automotive and aerospace industries. For example, materials that can withstand extreme temperatures could help in the design of more efficient engines.

The next few years will be busy for Abdeljawad and his team. They’ll be addressing cutting-edge scientific questions, working with new materials, and exploring an impressive range of possibilities emanating from the smallest of crystals. He says he finds motivation in working with his students and mentoring them through challenges and discoveries. He also fosters their sense of exploration and fun.

“Science is a hobby, not a job,” he says, “and we are having a blast.”