Materials researcher developing new method of growing bulk single-crystal nitrides—an advance that could lead to more-efficient, less-costly electronic devices and innovative manufacturing tools

Every discipline has its holy grail. For Siddha Pimputkar, an assistant professor of materials science and engineering in Lehigh University’s P.C. Rossin College of Engineering and Applied Science, it’s cubic boron nitride.

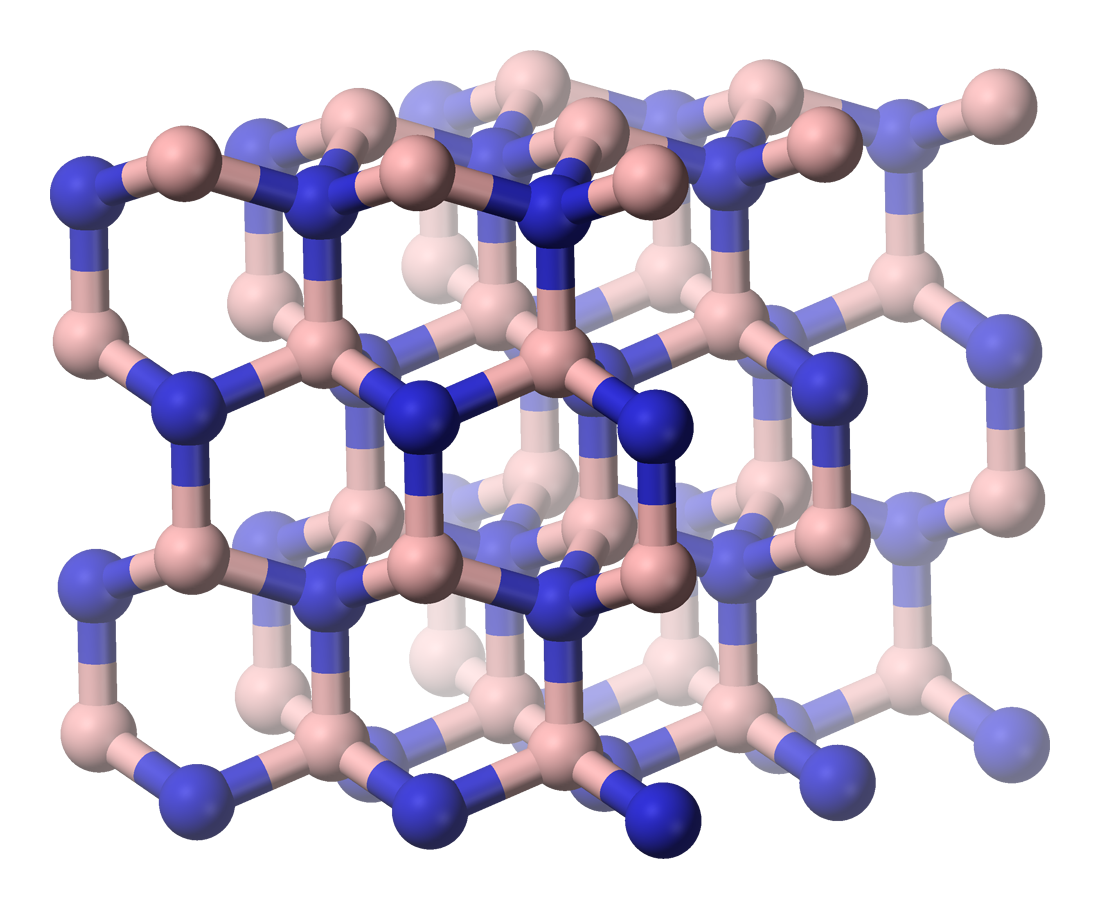

Nitrides are a broad set of chemical compounds in which a nitrogen atom is bonded to another element such as gallium or boron, or most metals.

Some of these nitrides are powerful semiconductors, more efficient than silicon, that ubiquitous presence in just about every device you power on or plug in. Some nitrides rival diamond in their hardness. Some are also capable of working in extreme environments. And some, like cubic boron nitride, can do all those things.

“Compared to silicon, cubic boron nitride has the potential to work under more extreme conditions including higher voltages and currents, like those found in the electrical power grid,” says Pimputkar. “The higher the voltage you can operate at, the less current is required to deliver the same amount of power. Just like power transmission lines, we would like to operate at the highest voltages possible to reduce the amount of current running through the system and resultantly reduce the waste heat that is generated due to inefficiencies in the system. This, in turn, allows one to eliminate or re-envision whole components of circuitry, thereby reducing the size of these electrical power converters, and hence, their cost.”

For example, he says, “one application is hybrid or electric vehicles, in which you wouldn’t need active cooling systems, including fans and associated controls, to keep the power control systems cool as you do with silicon-based technology. You can eliminate that complexity and those failure points because the properties of cubic boron nitride allow it to operate at much higher voltages and temperatures, making passive cooling acceptable.”

As a material, nitrides have exciting, far-reaching potential. They’re also really, really hard to make.

But Pimputkar’s proposal to develop an innovative system to do just that recently won support from the National Science Foundation’s Faculty Early Career Development (CAREER) program.

The prestigious NSF CAREER award is given annually to junior faculty members across the U.S. who exemplify the role of teacher-scholars through outstanding research, excellent education, and the integration of education and research. Each award provides stable support at the level of approximately $500,000 for a five-year period.

‘Pressure-cooking’ crystals

In this project, Pimputkar will attempt to overcome a long-standing and complex problem—the inability to inexpensively grow large, single-crystal nitrides with no defects—and then be able to scale that growth.

Size matters, Pimputkar explains, because with every increase in the diameter of a crystal, the final cost of electronics such as power converters used to charge laptops and phones goes down. (Once grown, a crystal resembles a solid chunk of matter, which is then cut into thin, round wafers that form the platform for making power electronic chips. The larger the wafer, the more chips you can make in a single processing step, making each chip cheaper.)

Defects obviously matter. Atoms within the crystal must be perfectly oriented to each other, and each neighbor needs to be of a specific element, he says, because any deviation will negatively affect the performance and capability of the material, and hence electronics.

And, finally, time matters. Typical bulk crystal growth methods for nitrides achieve growth rates on the order of 0.1 to 1 millimeter per day. That’s way too slow to make nitrides commercially viable, he says, especially when industry demands a large quantity of inexpensive wafers with a diameter of at least six inches.

It’s a complicated process to get right.

“We’ve figured out how to do it for silicon and for gallium arsenide [a semiconductor material used in solar cells and infrared LEDs],” says Pimputkar. “But for nitrides, we can’t use those same technologies because they rely on melting the material and re-solidifying it. When you heat a nitride, it typically falls apart on the atomic level into the metal and nitrogen gas. Current solutions overcoming this limitation yield some nitrides, though in an insufficient manner, and, importantly, they do not provide a pathway to cubic boron nitride and other very exciting nitrides. So I’m proposing a completely new approach.”

That approach involves a precursor containing lithium nitride, along with a specialized pressure cooker of sorts capable of containing the highly reactive lithium. Using the same principles you might employ to cook a roast beef in an Instant Pot, Pimputkar will be able to heat the system to a higher temperature and turn it into a liquid without the nitride falling apart.

“The nice thing about lithium nitride is it contains 25 percent nitrogen. Whereas with other liquids that dissolve nitrogen, you’re typically talking 10-6 or less, so millions of times less nitrogen available to form a nitride crystal,” he says. “So this is huge. From a chemical perspective, it dramatically promotes nitride growth.”

Pimputkar is also proposing a radical rethinking of how to initiate and sustain crystal growth using this system, in effect, overcoming known limitations of the art.

A system that scales

The potential impact, he says, is equally huge. Pimputkar believes his approach will allow him to make a range of nitride materials, including binary materials like gallium nitride and aluminum nitride (used in visible light LEDs, transistors, and diodes), and ternary materials like aluminum gallium nitride (found in UV LEDs and lasers and UV detectors, among other devices), as well as demonstrate the existence of other novel nitrides. He says it will also allow him to control the activity of each element in the nitride material, giving him control over the composition of the crystal he’s growing. And he’ll be able to—for the first time—grow large-diameter crystals of cubic boron nitride.

While all nitrides are hard to grow, cubic boron nitride is particularly challenging. Just like carbon can exist as diamond or as graphite—they are both 100 percent carbon—boron nitride can exist as hexagonal boron nitride (similar to graphite) or as cubic boron nitride (similar to diamond).

“A hexagonal arrangement gives you completely different properties,” says Pimputkar. “Cubic boron nitride is extremely hard, almost as hard as diamond. Hexagonal boron nitride is just like graphite. You can rub it, and it flakes apart. And it also has completely different thermal and electronic properties, so it’s undesirable to use in power electronic devices. It needs to be in this cubic arrangement to get those desired, extreme material properties.”

The one approach to growing cubic boron nitride that does not result in this hexagonal configuration uses high-pressure, high-temperature anvil systems.

“These systems can go to pressures that rival the pressures in the center of the Earth. You’re talking pressures of almost a million pounds of force per square inch, similar to the conditions in which diamonds want to grow,” he says. “It’s arguably the only way we can grow cubic boron nitride as single crystals to date. But it can’t be scaled. Only volumes the size of a few cubic centimeters can be subject to those pressures and that temperature. So the largest crystals we’ve been able to produce to date are only a few millimeters in diameter.”

Pimputkar says his system will overcome that hurdle. It will employ lower temperatures, which, in turn, will allow for dramatically lower pressure. “My system is easier to work with, and can be built for larger volumes, so we can now start thinking in terms of industrial scale, say, 6-, 8-, or 10-inch systems. Of course, we will start small, as having even a 1-inch diameter crystal would already prove transformative.”

And that could lead to an influx of low-cost, innovative products into the market. As superefficient semiconductors, gallium nitride and cubic boron nitride could have a huge impact on the $500 billion semiconductor industry, says Pimputkar. And while cubic boron nitride may be second to diamond in terms of hardness, unlike diamond, it can be used to cut ferrous metals. (Diamond is made of carbon, which can react with iron and change its properties.)

“This could lead to a new generation of tools for innovative manufacturing,” says Pimputkar.

Making an impact with materials

To fulfill the educational component of his CAREER proposal, Pimputkar will create the BUILDERS (Boldly Utilizing Innovation to Lead in Developing Engineers for Research and Science) program. It will connect middle and high school students from diverse backgrounds and from communities currently underrepresented in STEM with Lehigh undergraduates to learn how to build and use simple crystal growth apparati to synthesize single crystals. The goal is to get young students excited about STEM careers and build awareness around the impact that creating and manipulating equipment can have on our future capabilities.

It’s that potential for impact—both on industry, and in how we live our daily lives through the devices and systems we depend on—that motivates him.

“My philosophy is that you need to build new, innovative equipment to push the envelope and do new science and make new technology,” he says. “There are cascading consequences that come with making a new material. It can lead to new devices, more jobs, the ability to do new things. Just like the silicon revolution changed our way of life by enabling inexpensive computers, the internet, and, most recently, incredibly cheap solar cells, it is important to keep in mind that all of this started with its single-crystal synthesis.”

About Siddha Pimputkar

Siddha Pimputkar is a P.C. Rossin Assistant Professor in the Department of Materials Science and Engineering at Lehigh University. He joined the faculty of the P.C. Rossin College of Engineering and Applied Science in 2016. Previously, he was a postdoctoral researcher in the Materials Department at the University of California, Santa Barbara, where he also received his PhD in materials. He also holds a BS in mechanical engineering from Illinois Institute of Technology.

Pimputkar’s research focuses on synthesizing bulk and thin-film single-crystal, nitrogen-containing materials. He has published 21 papers, one book, and two book chapters on bulk gallium nitride growth and on the thermodynamic investigation of ammonothermal systems. He holds three patents (with 25 patent applications pending) and has been invited to speak at 18 conferences.

Pimputkar has obtained several grants from the National Science Foundation and has received awards from the NSF, the Department of Homeland Security, NASA, Lehigh, UC Santa Barbara, and Illinois Tech.

He is a member of the American Association for Crystal Growth (AACG), American Ceramic Society (ACerS), Materials Research Society (MRS), Institute of Electrical and Electronics Engineers (IEEE), Sigma Xi, and Tau Beta Pi. He has served on numerous program committees for conferences and has organized an ammonothermal summer school. He was a guest editor for the Journal of Crystal Growth, is the BN synthesis and characterization symposium co-chair for the upcoming AACGE/OMVPE 202, and is the conference chair for the International Workshop on Bulk Nitride Semiconductors (IWBNS) in 2022.