Quantum dots (QDs) are semiconducting nanocrystals prized for their optical and electronic properties. The brilliant, pure colors produced by QDs when stimulated with ultraviolet light are ideal for use in flat screen displays, medical imaging devices, solar panels and LEDs. One obstacle to mass production and widespread use of these wonder particles is the difficulty and expense associated with current chemical manufacturing methods that often requiring heat, high pressure and toxic solvents.

But now three Lehigh University engineers have successfully demonstrated the first precisely controlled, biological way to manufacture quantum dots using a single-enzyme, paving the way for a significantly quicker, cheaper and greener production method. Their work was recently featured in an article in The New York Times called "A curious tale of quantum dots."

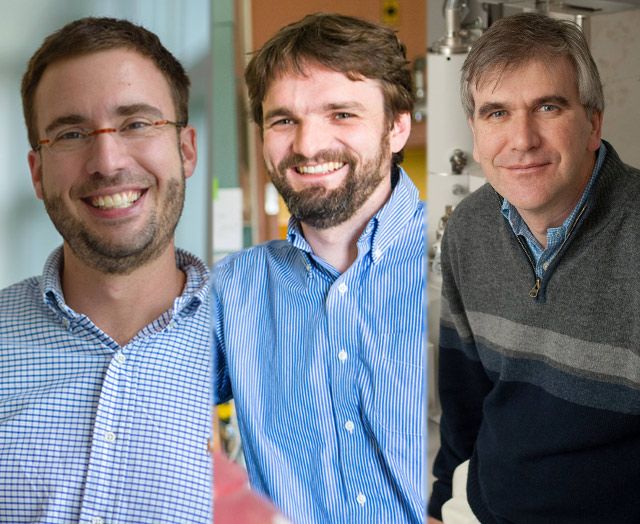

The Lehigh team -- led by chemical and biomolecular engineering associate professors Bryan Berger and Steven McIntosh and Chris Kiely, professor of materials science and engineering-- along with Ph.D. candidate Li Lu and undergraduate Robert Dunleavy, have detailed their findings in an article called "Single Enzyme Biomineralization of Cadmium Sulfide Nanocrystals with Controlled Optical Properties" published in the Proceedings of the National Academy of Sciences (PNAS).

"The beauty of a biological approach is that it cuts down on the production needs, environmental burden and production time quite a lot," says Berger.

In July of last year, the team's work was featured on the cover of Green Chemistry describing their use of "directed evolution" to alter a bacterial strain called Stenotrophomonas maltophilia to selectively produce cadmium sulphide QDs. Because they discovered that a single enzyme produced by the bacteria is responsible for QD generation, the cell-based production route was scrapped entirely. The cadmium sulphide QDs, as they have now shown in the PNAS article, can be generated with the same enzyme synthesized from other easily engineered bacteria such as E. coli.

"We have evolved the enzyme beyond what nature intended," says Berger, engineering it to not only make the crystal structure of the QDs, but control their size. The result is the ability to uniformly produce quantum dots that emit any particular color they choose--the very characteristic that makes this material attractive for many applications.

"If we're able to make more of the material and control how it's structured while maintaining its core functionality, we could potentially get a solar cell to assemble itself with quantum dots."

Read the full story from Lehigh University here and learn more in the latest issue of Lehigh Research.