Ask people what mechanical engineers do, and the answers usually follow a familiar script: They design engines, optimize machines, and make systems faster, lighter, more efficient. In other words—they build.

As a project engineer at consulting firm Thornton Tomasetti, Rossin College alum Sena Kizildemir 18G '23 PhD, sees things differently.

“Mechanical engineering isn’t only about creating what works,” she says. “It’s also about understanding what fails—and making sure it never happens in real life.”

Kizildemir’s work doesn’t often show up in headlines. If it does, it means something has already gone wrong. Instead, her job is to make sure that collapse, fracture, and failure remain hypothetical. “If I’ve done my job right,” she says, “you’ll never know it existed.”

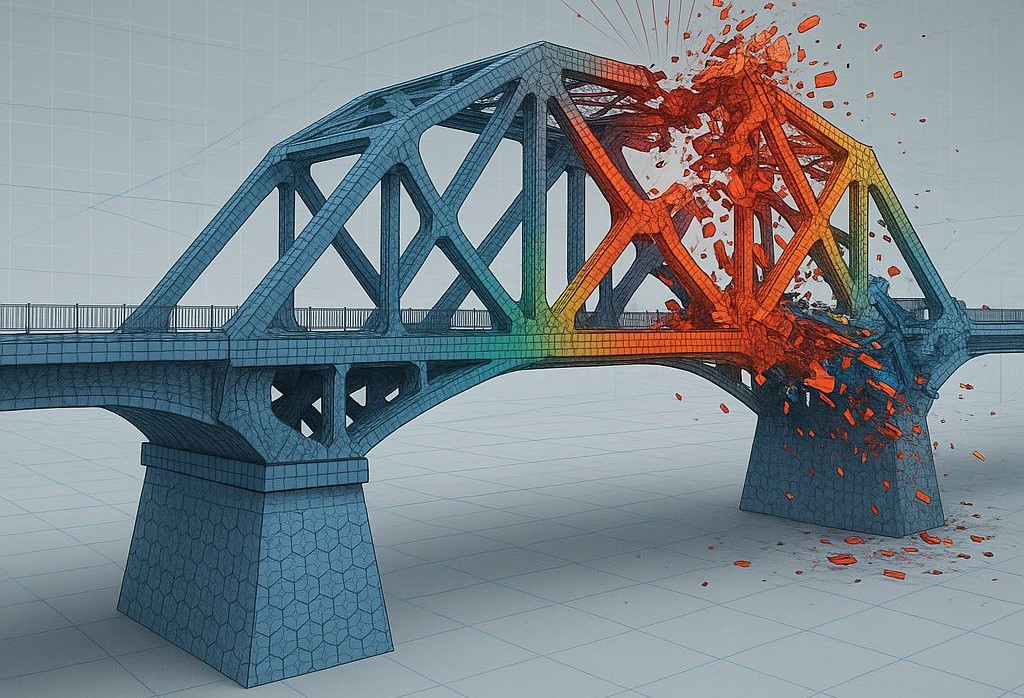

Her specialty is nonlinear finite element analysis (FEA), a powerful simulation tool that allows her to virtually re-create what materials and structures do under stress. Those factors go beyond wind and weight to include explosive blast, fire, impact, and progressive collapse—situations decision-makers can’t afford to test in real life.

“You can’t build a new bridge just to blow it up. You can’t set fire to a hospital wing to see how the structure responds. And you can’t test a stent inside a living artery until it fails,” she says. “But I can simulate those failures in a controlled, accurate way—and that allows teams to prevent them before they happen.”

One week, she might be simulating how heat propagates through a steel frame during a fire. The next, she’s modeling hidden subsurface fractures in a railroad rail—defects you can’t see, but that could cause a derailment if missed. In another project, she worked on digital rehearsals of building implosions, running collapse sequences hundreds of times before a single charge was placed.

“This isn’t about drama or destruction,” she explains. “It’s about decision-making. It’s about safety. I break things on a screen so that others don’t have to witness it in real life.”

Her work has a wealth of applications—a fact she’s eager to convey to the next generation of engineers. “The same mechanical principles govern everything,” she says. “Stress, strain, fracture. They apply whether you’re analyzing a turbine blade, a suspension bridge, or a biomedical implant. Once you understand how failure works, that knowledge transfers everywhere.”

In one of her favorite examples, she modeled the fatigue behavior of a cardiovascular stent, a small mesh tube used to keep arteries open. “It wasn’t so different from modeling a truss structure under cyclic loading,” she says. “Except this structure was inside a person. The stakes were different, but the physics were the same.”

She wants students to see that mechanical engineering isn’t confined to a single application or industry—it’s a universal language. You can move from structures to rails to biomedical devices, she explains, not by changing your identity as an engineer, but by understanding the underlying mechanics that everything shares.

And in a world filled with uncertainty—climate change, aging infrastructure, new energy systems—failure simulation isn’t just relevant. It’s essential.

“We don’t always get clear instructions in the real world,” she says. “Not everything is covered by a code or a manual. You have to think beyond the assumptions—beyond the ‘normal.’ That’s where simulation comes in. It lets you ask ‘what if’ in ways the physical world can’t afford.”

For young engineers, she hopes this message resonates: “There’s a quiet power in this kind of work. You won’t see headlines when a bridge that didn’t collapse or the building that withstood an extreme event. But that protection —that unseen success—is engineered.”

She knows that simulation may not always be visible to the public eye, but its impact is undeniable.

“It’s not about being seen,” she says. “It’s about making sure no one else has to see the worst-case scenario unfold.”

Dr. Sena Kizildemir is a Project Engineer at Thornton Tomasetti, where she leads advanced computational simulations to analyze how materials and systems behave under extreme conditions. With a dual background— a master’s degree in civil engineering and a PhD in mechanical engineering—her expertise spans nonlinear finite element analysis (FEA), fracture mechanics, and high-fidelity predictive modeling.

Her doctoral research, supported by the U.S. Federal Railroad Administration, focused on simulating fatigue-induced fractures in steel rails—capturing subsurface crack growth under complex residual stress fields, a phenomenon known for its extreme modeling challenges. Today, she applies simulation-driven insight across sectors including transportation, infrastructure, energy, and life sciences, helping solve complex engineering problems before they manifest in the real world.