When designing an airplane, a bridge, or a building, engineers face tradeoffs among factors like material strength, weight, and cost.

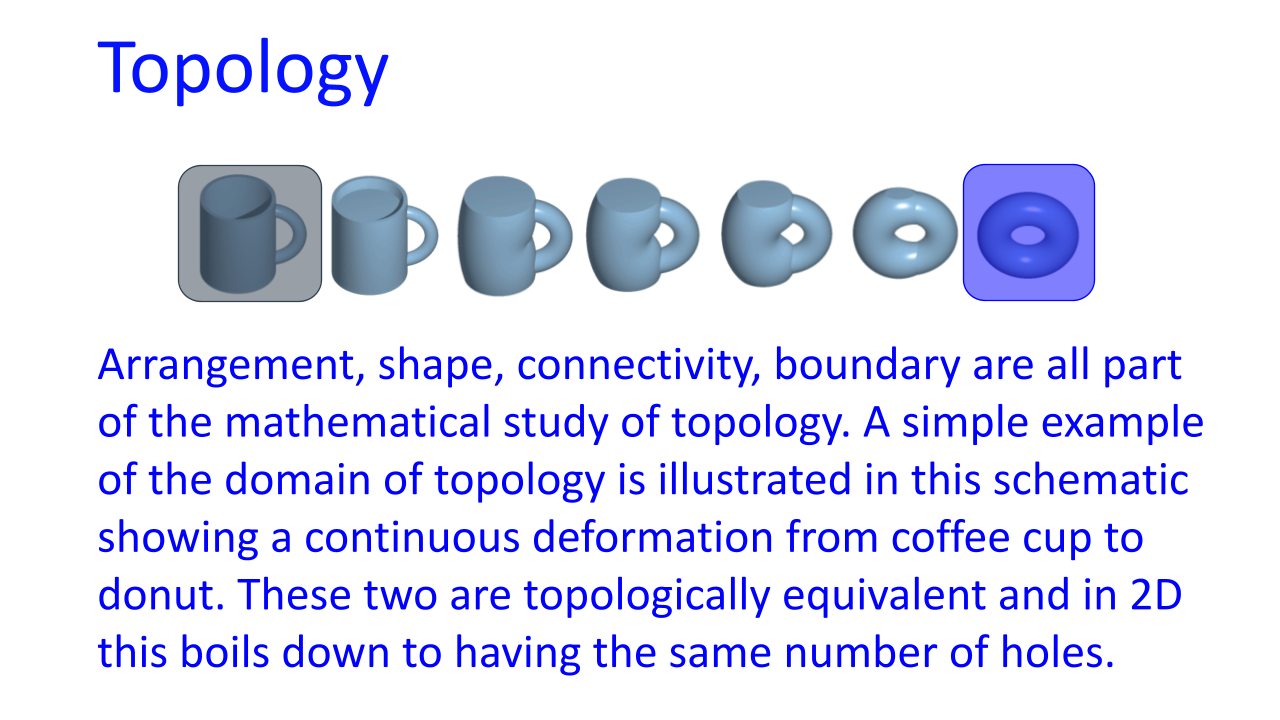

For decades, engineers have employed mathematical frameworks—through an approach called topology optimization—to determine efficient material distribution and connectivity in design, resulting in lightweight, durable, and high-performance solutions.

Today, thanks to advances in computational tools and additive manufacturing, says Natasha Vermaak, an associate professor of mechanical engineering and mechanics in Lehigh University’s P.C. Rossin College of Engineering and Applied Science, the benefits of topology optimization for materials design are within reach for a much wider swath of audiences and industries.

That includes the manufacturing of products like medical devices and consumer electronics, where critical materials can be scarce and/or expensive, as well as more unexpected fields like fashion, where sustainability concerns are taking on greater focus.

The common thread, says Vermaak, is the rise of additive manufacturing (also known as 3D printing). Additive manufacturing can produce geometrically complex components, which allows the near-full use of the freeform structural evolution of topology optimization.

In 2020, Vermaak received the Frontiers of Materials Award from The Minerals, Metals and Materials Society (TMS). This award is given to top-performing early-career professionals and includes the opportunity to organize a symposium on an emergent technical topic and curate a collection of articles on the theme as Guest Editor for a special issue of The Journal of the Minerals, Metals & Materials Society (JOM).

The vision for her 2020 TMS symposium on leveraging materials in topology optimization stemmed from Vermaak’s interdisciplinary mindset and her interest in understanding and implementing tools and methods from disparate fields.

“I wanted to engage researchers, designers and artists around the topic of the optimization of materials and structures, with additive manufacturing as a shared language,” she says.

Vermaak grew up watching her parents merge engineering design and art/craft skills on collaborative and imaginative projects, which inspired her appreciation for interdisciplinarity—something she sees as an integral aspect of modern science and engineering.

While she knew she wanted to reach out to fellow researchers in the topology optimization field, she also believed it was important to include individuals in her symposium who would not normally attend.

With this in mind, Vermaak contacted innovators Julia Daviy and Virginia San Fratello.

Daviy has paved the way for sustainable digital 3D-printed clothing, accessories, and jewelry, while San Fratello is a professor, design activist, author, and thought leader within the fields of additive manufacturing, architecture, and interior design.

Daviy, San Fratello, and Vermaak published the article, “Leveraging Materials in Topology Optimization: Inspiration from Design, Fashion, Art, and Architecture,” which prefaced a special issue of JOM published earlier this year. They are also preparing proposals for research grants on topics like design for additive manufacturing of structures that are seeded with end-of-life pathways (like fungi), and simultaneously optimizing manufacturing processes and materials for bio-textiles.

Daviy, San Fratello, and Vermaak published the article, “Leveraging Materials in Topology Optimization: Inspiration from Design, Fashion, Art, and Architecture,” which prefaced a special issue of JOM published earlier this year. They are also preparing proposals for research grants on topics like design for additive manufacturing of structures that are seeded with end-of-life pathways (like fungi), and simultaneously optimizing manufacturing processes and materials for bio-textiles.

Combining diverse perspectives, they say, can lead to inventive approaches.

“Most of the challenges that we face today cross disciplinary boundaries, and a diversity of perspectives is needed in order to drive impactful innovation,” Vermaak says.

For example, engineers and fashion designers working together can identify production models, based on both digital design and additive manufacturing, to better use recyclable/biodegradable materials with the potential to achieve near-zero levels of waste, carbon emissions, and water usage.

“It makes radically more sustainable manufacturing possible,” Daviy writes in the article.

San Fratello poses questions like: “What if the world’s waste materials could be transformed into sustainable building materials for the future? Can humble and traditional building materials, such as salt and mud, become sophisticated building materials for the twenty-first century?”

As a researcher, Vermaak sees untapped potential in thinking more broadly about materials, waste, economy, craft, and design.

“When we ask a broader audience of designers what they consider as materials objectives and constraints, and which materials they find most challenging to work with and why, new research questions that may require reimagining topology optimization frameworks themselves may emerge,” Vermaak says.

As a professor, Vermaak believes that nurturing a spirit of open curiosity and developing active listening skills can allow students to be inspired when surrounding themselves with diverse perspectives. She encourages students to take a variety of courses to get exposed to different methodologies and tools and develop an appreciation and aptitude for interdisciplinary thinking.

—Deirdre Kelshaw '22 is a student writer for the P.C. Rossin College of Engineering and Applied Science

About Natasha Vermaak

Professor Vermaak earned her doctorate in Materials (2010) from the University of California, Santa Barbara with Professor Anthony G. Evans. Before joining Lehigh University in 2013 as an assistant professor, she served as a postdoctoral scholar at the Institut National Polytechnique in Grenoble, France. Her research interests include multifunctional architectured materials and structures; application of mathematical optimization techniques for the design of material composition, microstructure and structural topology; modeling thermostructural and materials degradation and durability; design and optimization of bio-inspired actuators and sensors; ultra-light weight aerospace structures; thermoacoustics; and integrated computational materials engineering.