Developing ceramics with tailored geometries has long been a challenge. Achieving that kind of customization would allow materials to be designed with specific shapes and structures that make them stronger, more heat-resistant, or better at conducting electricity. Such materials could then enable improved technologies, such as more efficient electronics, better sensors, or even new types of energy devices.

Lehigh University materials science and engineering faculty members Helen M. Chan, New Jersey Zinc professor, and Jeffrey M. Rickman, Class of ’61 professor, recently received funding from the National Science Foundation to continue a project that is using a novel approach that could potentially revolutionize the fabrication of ceramics.

“This is a new type of ceramic material that hasn’t been studied much,” says Chan. “Typically, when you have a reaction, a certain type of microstructure develops. The systems we’re studying give us the potential for predetermining the microstructure, almost like templating.”

The goal is to produce a functional material with a tailored geometry—or microstructure—that will allow for a range of applications.

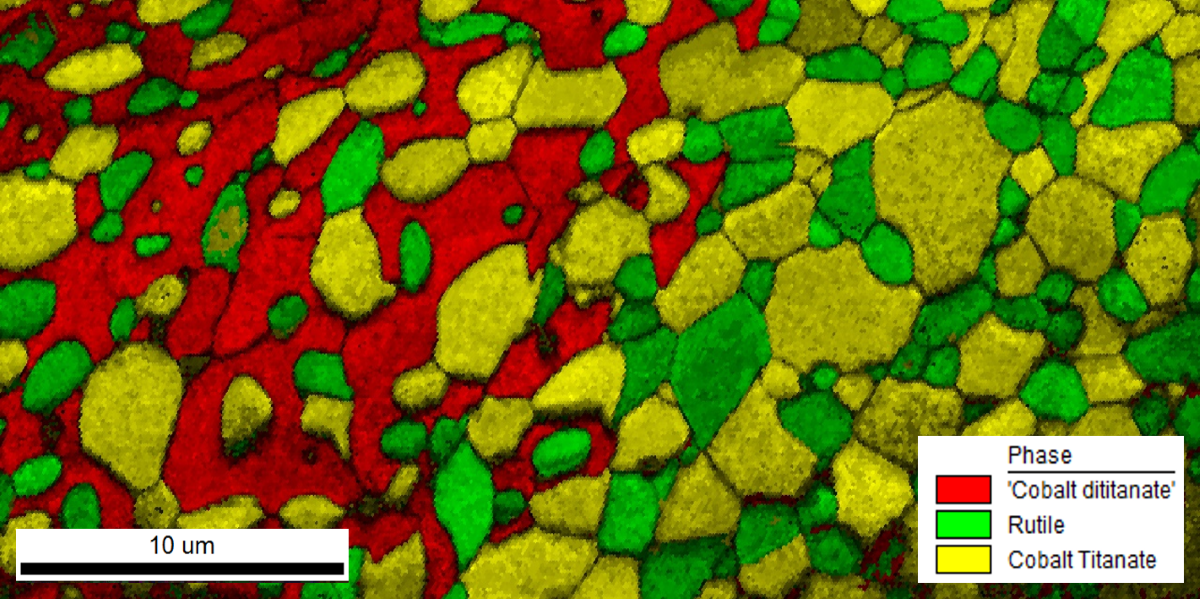

To that end, the team has exploited a method called solid-state synthesis, a process that involves a chemical reaction between two distinct phases, leading to the formation of a new, third phase (called a product phase) that has a specific, controlled geometry. In this case, the desired product phase is an entropy-stabilized ceramic that is thermodynamically stable at high temperatures. This approach is not just about creating any new material but about crafting it with precision, enabling new functionalities that were previously out of reach.

Chan likens it to laying two types of paving stones in your backyard for a patio.

“Grass grows at the interface between the different stones, and it’s the grass phase that we’re interested in,” she says. “By putting the stones in a certain arrangement, we’re controlling where and how much grass there is. We want to control that third phase, the grass, if you will, in the reaction.”

The team made an unexpected and unusual discovery about this third phase earlier in their research.

“That third phase was a single crystal, and it’s usually very difficult to get single-crystal growth that you can template,” she says. “The combination of the single-crystal interface with those other two phases could, in fact, contribute to the functional properties of the system.”

The ability to produce single-crystal phases with specific microstructures could lead to advances in electronics, energy conversion, and more. For example, the resulting materials could be used in thermoelectric devices that generate electricity from waste heat. “These thermoelectrics are highly desirable because they can convert heat energy into a voltage, which is a more useful form of electrical energy," says Rickman.

Beyond these applications, the research, which combines experimental work with advanced modeling, also aims to answer fundamental questions about the processes involved in solid-state synthesis.

“We want to understand the physics behind the reaction, and the modeling aspect will allow us to model the formation of this new useful phase,” says Rickman. “How do the atoms come together? How does the material deform during a reaction? How does this long-range transport of the atoms at the interface occur? It’s an interesting project in that we’re both producing new and useful products, but we’re also contributing to the fundamental science driving these reactions.”

About Helen M. Chan

Helen Chan is the New Jersey Zinc Professor of Materials Science and Engineering in Lehigh University’s P.C. Rossin College of Engineering and Applied Science. She received her B.Sc. and PhD from the Department of Materials Science & Technology at Imperial College (University of London). Her research interests include the application of reactive processing to fabricate unique ceramic/metal structures; the processing, properties, and advanced characterization of high-entropy alloys; the mechanical behavior of ceramic composites; and the role of interfacial chemistry in determining the elevated temperature mechanical behavior of ceramics. Chan has authored more than 200 publications, given hundreds of talks and presentations, and holds five U.S. patents. She is a Fellow of the American Ceramic Society and currently serves on its Board of Directors. Chan has won numerous awards including a Fulbright Scholarship to Austria (2016) and Lehigh’s Hillman award (2017).

About Jeffrey M. Rickman

Jeffrey M. Rickman is the Class of ’61 Professor of Materials Science and Engineering in Lehigh University’s P.C. Rossin College of Engineering and Applied Science, where he has been a faculty member since 1993. His research spans materials informatics, focusing on the characterization of abnormal grain growth in ceramics, the prediction of plastic behavior in high-entropy alloys, and the modeling of dislocation dynamics and phase transitions. Rickman has received funding from the NSF, ONR, AFOSR, and ARO. He is an editor for Acta Materialia and Scripta Materialia, with around 150 publications. Rickman was elected a Fellow of ASM International in 2019 and the American Ceramic Society in 2021. He holds undergraduate degrees in physics and mathematics from Miami University and a PhD in physics from Carnegie Mellon University.