When Jack Riffle ’26 was a 7-year-old Boy Scout touring NASA’s Jet Propulsion Laboratory (JPL), he didn’t realize the visit would set the course of his future. Growing up just 15 minutes from the lab in Pasadena, California, afforded him an early look at JPL's pioneering work in space robotics.

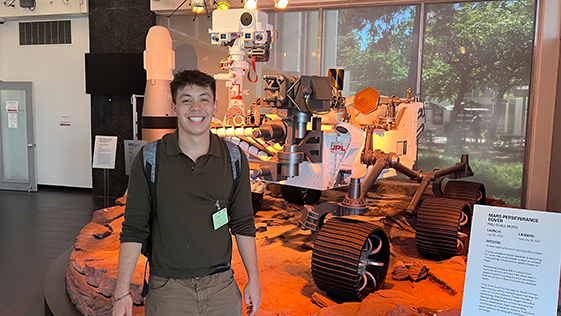

The tour remains a vivid childhood memory: Riffle recalls standing in the Mars Yard, where engineers test full-scale rover prototypes, and peering into the high bays where spacecraft are assembled. He also visited the Deep Space Operations Control Center, the nerve center for NASA’s interplanetary communications.

“The control center was the most high-tech place I’d ever seen,” he says. “And looking at the rovers up close gave me a sense of just how big and complex they were—and how much work went into building them.”

That childhood awe transformed into ambition. Drawn to math and science, Riffle is studying mechanical engineering at Lehigh, with a minor in aerospace engineering sparked by first-year aerodynamics elective.

Riffle says he appreciated how Keith Moored, an associate professor of mechanical engineering and mechanics, taught the subject. Moored started each class with a “Plane of the Day” segment, showing a model airplane and explaining its aerodynamic design. “It helped me make the mental connection between theory and real-world engineering,” Riffle says.

His fascination with JPL never faded. Having grown up hearing about the lab’s internship program, Riffle applied as a sophomore, reaching out to contacts across JPL to express his interest. After several months of suspense—and nearly accepting an internship elsewhere—he emailed the JPL hiring manager one last time. Soon after, he received an offer.

“It was such a relief,” says Riffle. “I was losing hope, but then I got to tell my parents not only that I’d be interning at NASA, but also that I’d be returning home for the summer.”

Riffle joined the Mars Sample Return (MSR) mission in a role focused on the Sample Retrieval Lander (SRL), the spacecraft responsible for collecting rock samples gathered by the Perseverance rover and launching them back toward Earth. The Mars Ascent Vehicle (MAV), a rocket (about 7 feet long) contained within the lander, will carry those samples into orbit, beginning their journey home.

His specific assignment was to help design, build, and test a new door system for the MAV compartment. The original concept, a simple hinged door that opened before launch, had sealing issues. The new design replaced that mechanism with a specialized foam barrier—sturdy enough to protect against Mars’ harsh environment but fragile enough for the MAV to blast through during launch.

Riffle had to characterize this interaction and ensure that the door wouldn’t affect forces that could damage the MAV. He built a test bed and, using a mock-up rocket, simulated the launch sequence with his team. They used a large piece of insulation foam to verify the mechanical design of the test rig for later evaluation of the door.

Beyond his project, Riffle took full advantage of his time at JPL. He revisited the Mars Yard—this time as an intern instead of a Boy Scout—and observed spacecraft in development, including ASTHROS, a balloon-borne observatory set to launch from Antarctica to study infrared light from near-space altitudes.

“At JPL, they often say they design one-of-a-kind things,” Riffle says. “It’s not like I had a product I was trying to optimize, but instead, I was building something that was entirely new.”

He credits his mentors and technicians at JPL for their guidance and collaboration.

“If I had specific questions about the test bed, they would take the time to talk with me,” he says. “The NASA technicians also helped me build and design the product from the ground up.”

Riffle attributes his readiness for the internship to Lehigh’s hands-on engineering education. The design labs in Wilbur Powerhouse and across the Rossin College, he says, gave him practical experience that set him apart from other interns. While some of his peers focused heavily on theoretical models, his designs emphasized ease of fabrication and cost-effectiveness.

“The vast majority of my test bed was made from an aluminum extrusion that I knew was cost-effective,” he said. “I was able to build my product without any pushback because I kept the cost down, which is something Lehigh emphasizes in its labs.”

Riffle is now enrolled in Rossin College’s Bachelor's to Master's Accelerated Program, and he plans to continue exploring both aerospace engineering and his growing interest in the energy industry.

His summer at JPL reaffirmed the dream sparked by that childhood tour—the desire to be part of something bigger than himself.

“Being part of something extraordinary often means doing the small things extraordinarily well,” Riffle said. “Big missions are the result of thousands of people doing exceptional work on their piece of the mission.”

—Andrea Palladino '26 is a student writer for the P.C. Rossin College of Engineering and Applied Science