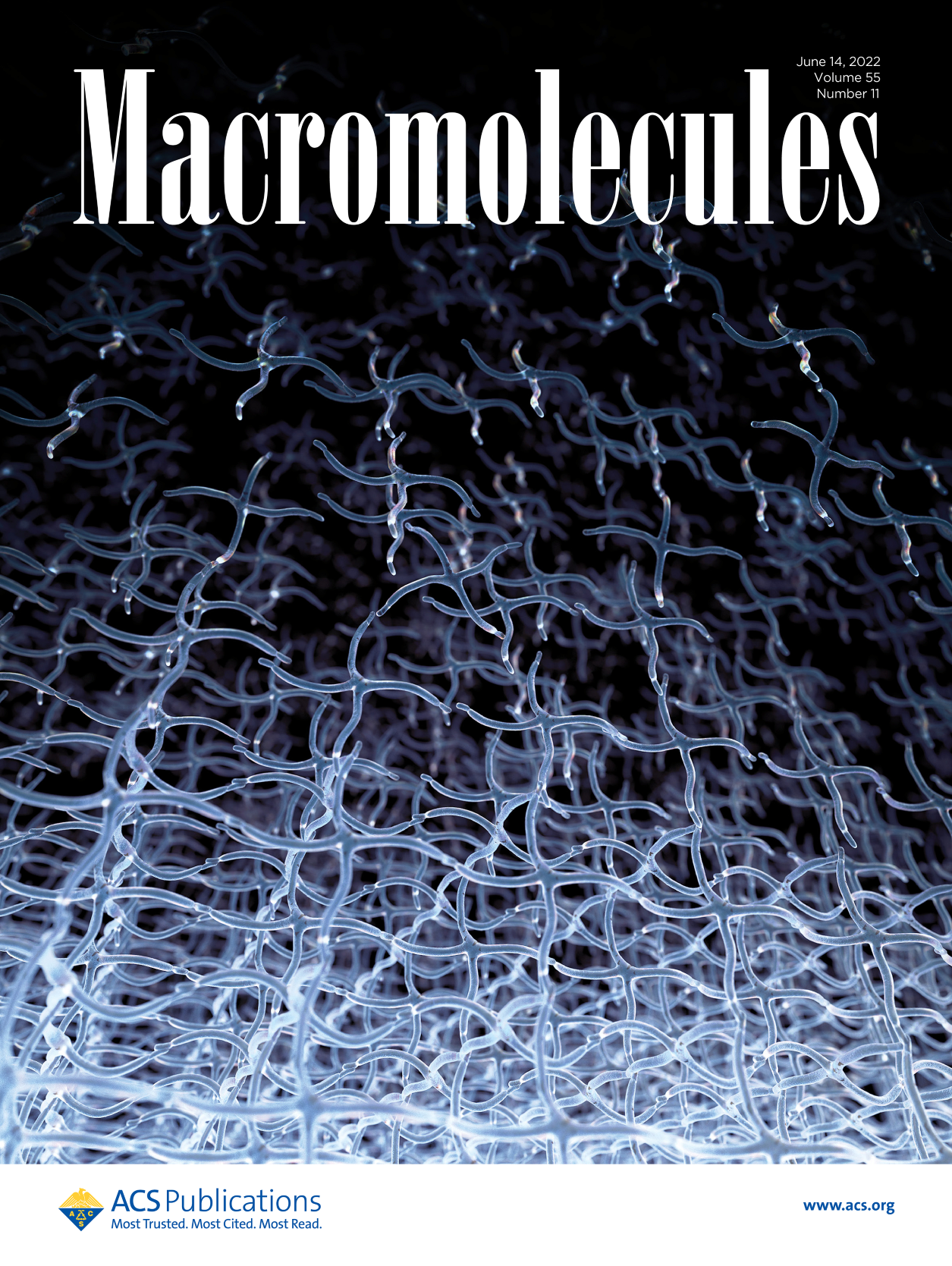

Hydrogels—networks of highly absorbent polymer chains—play a key role in the development of cutting-edge implantable devices for wound healing. When a hydrogel scaffold is encapsulated with stem cells and injected into an injury site, the cells can migrate to the damaged area and accelerate healing. Designing an effective material for this emerging technique, however, requires closely matching the properties of the implant to that of the native tissue.

Hydrogels—networks of highly absorbent polymer chains—play a key role in the development of cutting-edge implantable devices for wound healing. When a hydrogel scaffold is encapsulated with stem cells and injected into an injury site, the cells can migrate to the damaged area and accelerate healing. Designing an effective material for this emerging technique, however, requires closely matching the properties of the implant to that of the native tissue.

“If you want to repair something like the ACL, which tends to have a really steep change in stiffness as you move from the center of the tendon out toward the bone, you need a material that also exhibits that strong change in stiffness,” says John McGlynn ’22 PhD (pictured), who recently graduated and is now at Merck.

McGlynn—together with his advisor and co-author Kelly Schultz (pictured), an associate professor of chemical and biomolecular engineering—developed a method that will help researchers better quantify the stiffness of nonuniform hydrogels and, therefore, better match the properties of human tissue. That method is described in a paper recently published in Macromolecules, with McGlynn as lead author.

“In our lab, we hadn’t investigated materials with nonuniform stiffness," he says. "We wanted to see what the impact of these changes in stiffness had on the migration and motility of cells encapsulated in the network.”

“In our lab, we hadn’t investigated materials with nonuniform stiffness," he says. "We wanted to see what the impact of these changes in stiffness had on the migration and motility of cells encapsulated in the network.”

While hydrogels with a stiffness gradient can better mimic native tissue, he says, they can also yield better control over certain aspects of the stem cell, such as its shape, its rate of migration, and its lineage specification, which determines what type of cell it will become.

“If you can precisely control the changes in the stiffness of the material, you could better control cell behavior, which could translate into more controlled cell delivery and better wound repair,” he says.

The method he devised to quantify stiffness involves using ultraviolet (UV) light exposure. By varying the degree of UV light intensity across regions of the hydrogel, he could change the extent of reaction, or the degree by which polymers cross-linked, causing the region to autofluoresce. The brighter the region, the stiffer the material. McGlynn says that brightness is likely due to a phenomenon called aggregation-induced emission. He says this no-touch technique of measuring stiffness is an improvement upon a common method called atomic force microscopy, which involves applying a force to the hydrogel and measuring its response.

“That technique can actually damage the native structure, and there are other assumptions involved with it that can invalidate your measurements,” he says.

For researchers focused on improving the design of implantable devices that will help patients heal faster with less pain, this new method is yet another important step forward. And it isn’t limited to the medical field.

“There’s a huge library of hydrogels, with applications in areas like cultured meat, and this technique is applicable to many of them,” says McGlynn. “We hope that other researchers will use it to enhance their own work.”