Scientists in the United States and China have announced a discovery that they believe could enable the engineering of alloyed materials that are stronger, more ductile and possess superior electrical, magnetic and physical properties.

Writing in Science, the nation’s leading scientific journal, the researchers said they had found a surprising degree of order in the interior grain boundaries—the interfaces between crystalline grains—that determine the properties of polycrystalline materials such as metals and ceramics.

Scientists have traditionally identified two categories of grain boundaries in polycrystalline materials, says Martin P. Harmer, the Alcoa Foundation Professor of Materials Science and Engineering at Lehigh.

Special grain boundaries occur at a relatively small fraction of the internal interfaces of a material when adjoining lattices (the 3D arrangement of atoms inside a crystal) of individual grains join together with little mismatch and form a periodic or patterned superstructure.

General grain boundaries are more common and occur in the interior of a material when there is a large misfit between adjoining grains and no matching of the adjacent crystal lattices.

“General grain boundaries tend to be the weak regions of an engineering material,” says Harmer, one of the coauthors of the Science article. “But while special grain boundaries typically have much better properties, general grain boundaries are more prevalent, and therefore more important, because they determine the bulk properties of a material.”

General grain boundaries have been difficult for scientists to study, says Harmer, because they are harder to access than special grain boundaries and because they can form a wide variety of possible configurations.

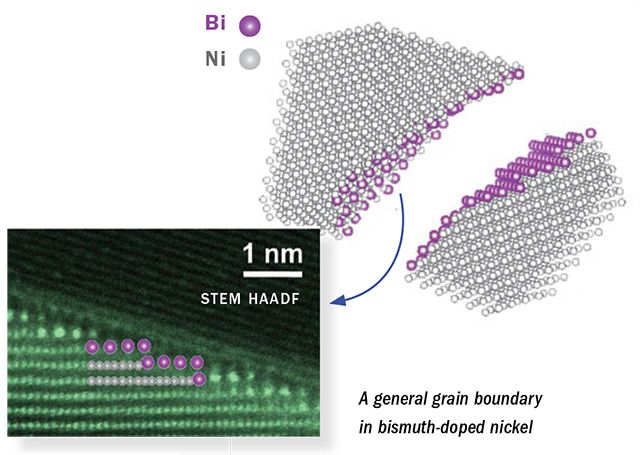

Using atomic-resolution electron microscopy and numerical calculations, Harmer and his colleagues have succeeded in characterizing 12 randomly chosen general grain boundaries in polycrystalline nickel doped with bismuth. The six-year project has been funded by the Office of Naval Research through its Multidisciplinary University Research Initiative (MURI).

The researchers found that bismuth atoms adsorbing, or segregating, at the general grain boundaries of nickel formed superstructures whose weak bismuth-bismuth bonds at critical junctures caused the alloy to become brittle.

“This discovery,” they wrote in Science, “shows that adsorbate-induced superstructures are not limited to special grain boundaries but may exist at a variety of general grain boundaries, and hence they can affect the performance of polycrystalline engineering alloys.”

“We believe that, for the first time, we have discovered superstructures at general grain boundaries in a metal alloy,” says Harmer. “Until now, this had been a very hidden phenomenon in metals.

“This breakthrough helps us understand why, in the case of nickel-bismuth, the alloy embrittles. But beyond that, there will potentially be superstructures in general grain boundaries which enhance a material’s performance, strength and ductility.

“New tools and models make it possible to see things in general grain boundaries that we couldn’t see 10 years ago. These are changing how we think about materials, and how we engineer them.”