Lehigh receives a MURI grant for atomic-scale interphase research

A group of universities led by Lehigh has received a $7.5-million grant from the U.S. Department of Defense (DoD) to study grain-boundary interphases and their effects on the mechanical, electrical and thermal properties of strategic engineering materials.

The five-year project was one of 27 chosen for funding from 113 proposals submitted this year to DoD’s Multidisciplinary University Research Initiative (MURI) program.

The award by DoD’s Office of Naval Research is to Lehigh, Carnegie Mellon, Clemson and Kutztown Universities, and the University of Illinois at Urbana-Champaign. The principal investigator, Martin Harmer, directs Lehigh’s Center for Advanced Materials and Nanotechnology.

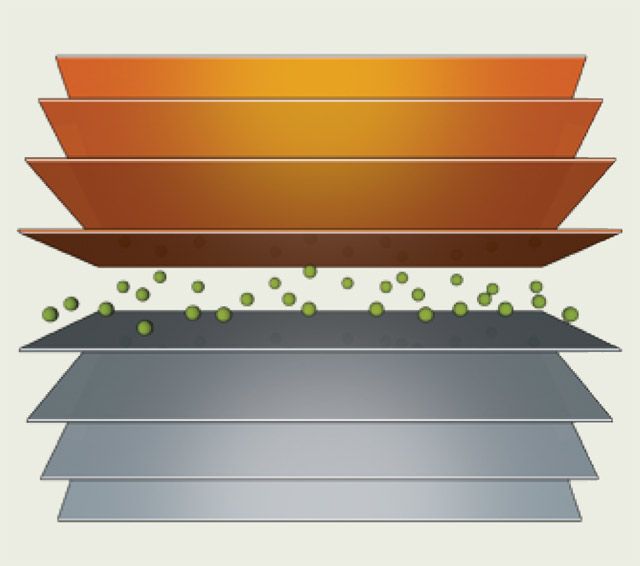

The researchers are specifically interested in the atomic structure of grain-boundary interphases, also known as interphase complexions.

Grain-boundary interphases were studied for many years before Shen Dillon, working as a graduate student with Harmer in 2006, identified six distinct interphase structures, or complexions, in pure and doped polycrystalline alumina.

Dillon, now an assistant professor of materials science and engineering at Illinois, used Lehigh’s powerful aberration-corrected transmission electron and scanning transition electron microscopes to obtain the high-resolution images needed to identify the complexions.

Since then, complexions have been identified in other ceramics and metal alloys.

“During the processing of ceramics and metals, the transition from one type of complexion to another can lead to abnormal grain growth,” says Harmer. “This is a major problem when you want to produce a high-quality material with a uniform grain size, and it must be avoided when fabricating a nano-grained material.”

With help from Gregory S. Rohrer, director of Carnegie Mellon’s Materials Research Science and Engineering Center, Harmer’s group has combined theoretical thermodynamic models with experimental observations to show that such detrimental transitions can be prevented by controlling two factors – the amount of a dopant and the temperature during processing.

“This new funding will allow us to extend our studies to determine the role that interphase complexions play in the properties of a wide range of materials, such as nickel alloys and tungsten carbide-cobalt composites whose properties are well known,” says Harmer.

“Our goal is to create new classes of materials, such as nano-grained metal-complexionized ceramics that exhibit both the hardness of a ceramic and the superior toughness of a metal. Such a combination is not yet available even with today’s most advanced material systems.”