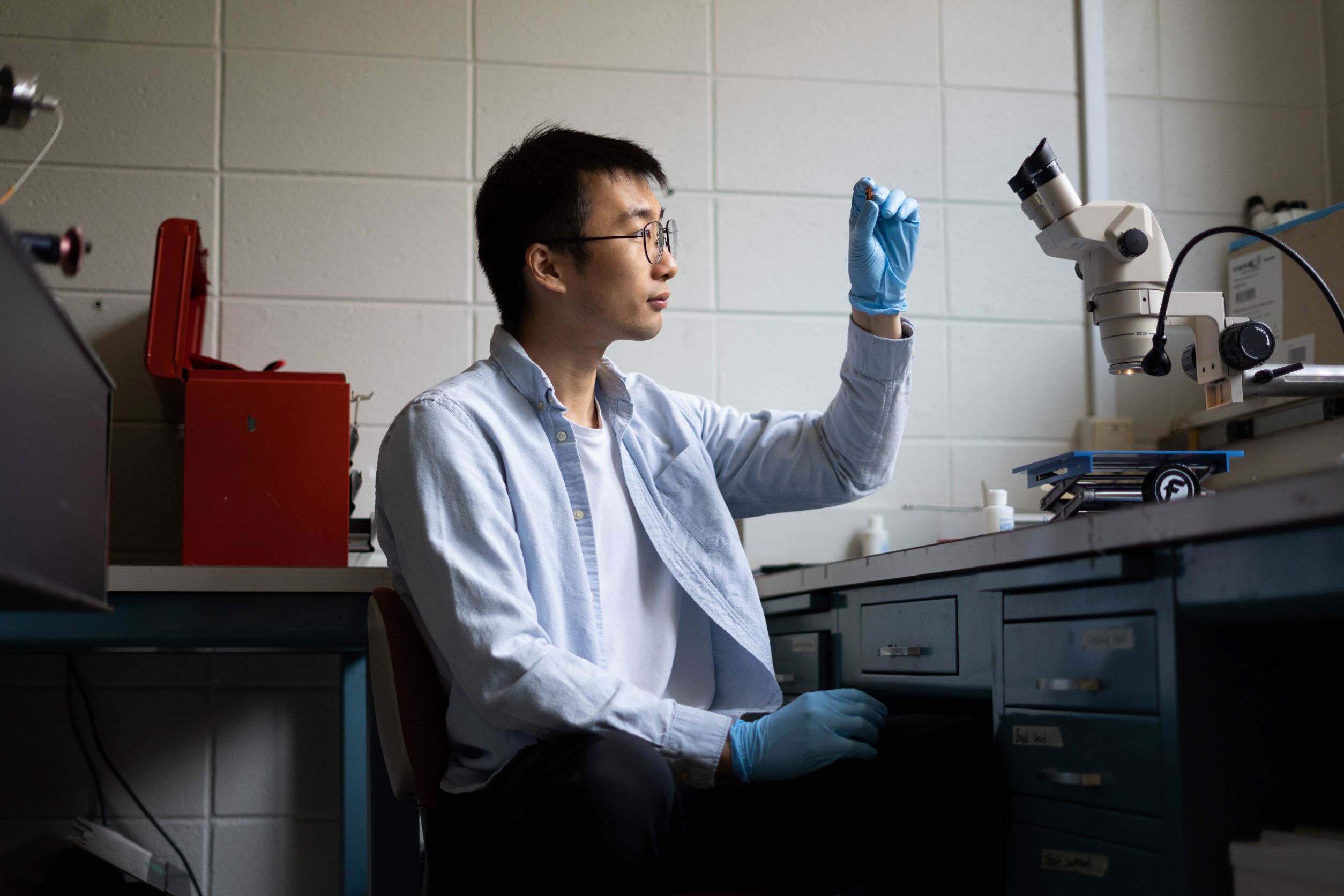

When Fei Jia goes to work in Lehigh’s Sinclair Laboratory, he knows there’s a possibility that things might get a little chilly.

On days when the PhD student in electrical and computer engineering isn’t fabricating laser chips in the Integrated Nanofabrication and Cleanroom Facility, he’s likely penetrating the polyethylene sheets with highly specialized lasers that require extremely cold temperatures (i.e., 60–70 degrees Kelvin, or about -350 degrees Fahrenheit).

Jia isn’t actually exposed to the extreme conditions: The chill is contained inside a portable, electrically operated cryocooler that houses the semiconductor laser chips. However, he is gaining hands-on experience with cutting-edge lasers that, until recently, had been notoriously difficult to tap into for applications because of their unusual physics.

Jia works on quantum cascade laser (QCL) technology as a graduate research assistant for Sushil Kumar, an associate professor in the Department of Electrical and Computer Engineering who is affiliated with Lehigh’s Institute for Functional Materials and Devices (I-FMD).

A QCL is a type of semiconductor laser that could fit on a nickel and emits terahertz waves—radiation that lies between microwaves and infrared light along the electromagnetic spectrum.

Terahertz waves can be useful because (in the same way that visible light can create a photograph, radio waves can transmit sound, and X-rays can render the inside of the human body) they can also create images and transmit information.

That means they can penetrate common packaging materials such as plastics, fabrics, and cardboard, and are also effective in optical sensing and analysis of a wide variety of chemicals. And thanks to its relatively low energy, terahertz radiation doesn’t cause any change in chemical structure—as opposed to UV radiation or X-rays—so it is harmless to human tissue.

“It is useful to detect illegal substances hidden in things like briefcases, shoes, and clothes,” Jia says. “In the future, terahertz scanners may replace X-ray scanners or microwave scanners, the type used at airports, due to their safety and/or better image resolution.”

Jia’s research focuses on three main areas: fabricating the laser chips that emit terahertz waves; engineering the light beams that come out of the chips after he fabricates them; and analyzing chemicals by passing the terahertz laser through them.

Currently, Jia’s experiments pass the terahertz laser light through a “sandwich” of high-density polyethylene sheets. He documents the power it transmitted, determines the thickness of the gap between the two sheets, and records the properties of the test liquid or solid that’s put in between.

“I really enjoy fabricating these devices,” Jia says, “because I get to use different machines and do a lot of experiments with them in the cleanroom.”

As part of the fabrication process, Jia bonds two ultrathin wafers together. Each one is around 700 micrometers thick; their combined thickness is about a tenth of a centimeter, so precision is key. And to make the process even more difficult: There can’t be even a speck of dust between the wafers, otherwise they’ll break apart during the experiment.

“You spend one week fabricating those wafers, and then you find the dust and realize maybe half your wafers are wasted,” Jia says.

Those types of setbacks are rough, but for Jia, the hardest part of all is waiting.

“We spend one to three months doing the whole fabrication process,” Jia explains. “After that, we start to test them all in our lab; but only after the test can we check if they’ve survived or not. You put all your effort into fabricating these devices, and sometimes you just have to worry about it for three months.”

Despite all the challenges and frustrations that are part and parcel of his work, Jia knows he’s contributing to what could be groundbreaking terahertz technology.

In 2018, results from work in his advisor’s lab were published in the journal Nature Communications and drew a swell of attention as a major advance in terahertz QCL technology. Then, in 2020, Kumar (pictured) reported in the journal Optica another technology breakthrough: developing a new technique that achieved a record-high power output for terahertz lasers. Their laser produced the highest radiative efficiency for any single-wavelength QCL to date.

In 2018, results from work in his advisor’s lab were published in the journal Nature Communications and drew a swell of attention as a major advance in terahertz QCL technology. Then, in 2020, Kumar (pictured) reported in the journal Optica another technology breakthrough: developing a new technique that achieved a record-high power output for terahertz lasers. Their laser produced the highest radiative efficiency for any single-wavelength QCL to date.

Training with a leader in the field was exactly what Jia envisioned when he was contemplating pursuing his PhD.

After graduating in 2018 from the University of Central Florida with a master’s degree in optics and photonics, Jia began an internship in the fiber optic technology research group of network infrastructure company Panduit and noticed that most of his colleagues had doctorates.

“Our group used complex mathematical models in their research, and I was very curious about them because they describe the results of your experiment,” Jia says. “I decided to get my PhD and to gain deeper and broader ways of thinking about optics and photonics.”

Jia is in year two of his PhD studies, but he’s already excited about applying the possibilities of terahertz laser technology in the next phase of his career.

“I am learning a lot and doing a lot of experiments in the PhD program here at Lehigh, and I want to take advantage of those experiences and try to apply the technologies to industry.”

—Story by Steve Neumann; Featured photos by Christa Neu