There’s a new resident in the basement of Lehigh University’s Whitaker Lab that’s been attracting a lot of attention even before getting fully settled in.

There’s a new resident in the basement of Lehigh University’s Whitaker Lab that’s been attracting a lot of attention even before getting fully settled in.

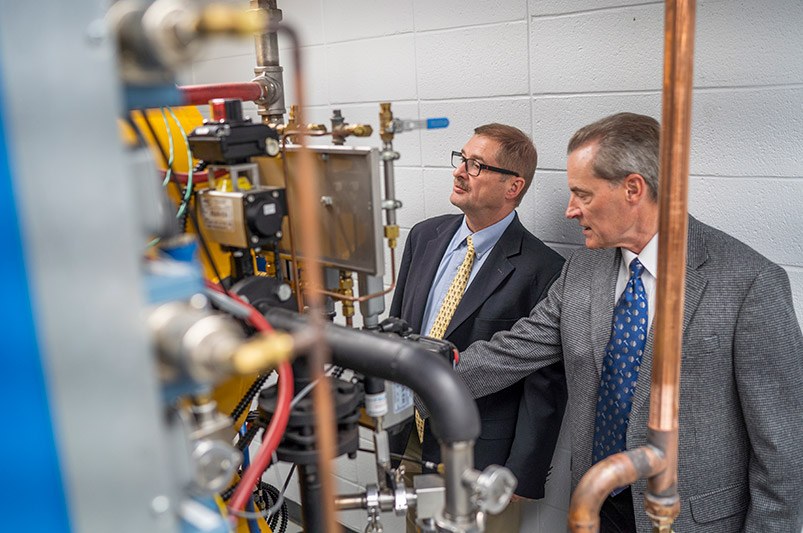

“People have been knocking on my door asking, ‘Is it ready?’” since the day the vacuum heat treating and brazing furnace was delivered, says Wojciech Misiolek, professor and chair of the Department of Materials Science and Engineering at the P.C. Rossin College of Engineering and Applied Science.

The new addition, a $300,000 commercial-grade model called The Mentor, was donated by thermal processing company Solar Atmospheres and its CEO and founder, William R. Jones. Its sister company, Solar Manufacturing, designs and builds vacuum furnaces at its location in Souderton, Pennsylvania, just 23 miles from Lehigh’s campus.

“This is a very powerful, advanced piece of equipment that will allow us to conduct important experiments in our metallurgy teaching and research, especially around additive manufacturing, which is a hot topic these days, explains Misiolek. “And we will challenge ourselves to use it up to its full capabilities for heat treatment of metals.”

Those capabilities include a chamber that can hold up to 250 pounds, with a hot zone that can reach a maximum temperature of 2800⁰F. Heat treating metals improves and/or tailors their properties—hardness, strength, ductility, and so on—by changing the microstructure of the materials.

Although Jones has been developing vacuum furnace and processing technology in the region for more 40 years, he was connected to Lehigh only recently through local chapters of ASM International, of which he and Misiolek are both Fellows.

Laura Moyer, who manages metallography, light optical, microscopy, and X-ray diffraction labs at Lehigh and serves as chair of the Lehigh Valley chapter of ASM International, and Tim Steber, a regional sales manager for Solar Atmospheres and past chair of ASM Philadelphia Liberty Bell Chapter, coordinated to take Jones on a campus visit.

“Bill was thoroughly impressed during his tour of the metallurgical labs,” says Steber, “and he saw an opportunity to advance Lehigh’s capabilities and launch them into another area.”

In June, the Solar Atmosphere employees delivered furnace, freshly painted in the company’s vibrant blue and yellow colors, to the site in as turnkey fashion as possible.

“Not only did they give us this compact yet highly complex piece of equipment,” says Moyer, “they built and donated the transformer and water-cooling system that sits on the other side of the wall and was specifically designed for the application.”

According to Steber, Solar Atmospheres conducts thermal processing for a wide range of industries—heat-treating everything from sink bowls to artificial knees to missile and jet engine components.

At Lehigh, “a lot of our students go on to work in facilities where they are using heat-treat furnaces for materials,” says Moyer.

“With this donation,” adds Misiolek, “suddenly you have the industry-grade equipment. It’s not a miniature version, it’s what you will see out in the field. Our educational system at Lehigh is very hands on, and we have a reputation for that. This furnace will increase opportunities for our undergraduate and graduate students and help them hit the ground running when they go into industry.”

The corporate partnership has continued to develop through Solar Atmosphere’s participation in Lehigh’s Summer Engineering Institute.

The corporate partnership has continued to develop through Solar Atmosphere’s participation in Lehigh’s Summer Engineering Institute.

Moyer directs this outreach program, which brings talented, motivated high school students from underrepresented groups to the Rossin College each summer. The two-week lab-based, research-centric experiences are designed to expose teens to the challenges and thrills of science, technology, engineering, and math in a cooperative, team-based environment.

As part of this year’s activities, students toured Solar Atmosphere’s campus and got an up-close look at materials and processes the company uses for applications in a variety of markets. Students were impressed by to see the “far-reaching effects of local manufacturing.”

“These types of tours give SEI participants a different perspective on manufacturing, and observing these well-kept, organized facilities dispels any preconceived notions,” says Moyer. “Most of these students don't realize there are businesses within their communities that design and fabricate products used all around the world in many different applications. They also see these companies as possibilities for a future career.”

Moyer plans to further incorporate Solar Atmospheres and Solar Manufacturing tours, lectures, and seminars into the undergraduate curriculum as well as other summer outreach programs in the future.

—Katie Kackenmeister is assistant director of communications for the P.C. Rossin College of Engineering and Applied Science