You may not have heard of the word tribology, says Brandon Krick, but in your everyday life you cannot avoid it.

Tribology, says Krick, an assistant professor of mechanical engineering and mechanics, is the science that deals with friction, wear and lubrication. It seeks to answer a basic question: How do two surfaces interact when they make contact with each other? Think of your car tires gripping a road surface or your shoes gaining traction on a wet sidewalk, says Krick. Rub your finger across the top of your desk. Slowly, imperceptibly, it will begin to remove material from the surface.

Tribology comes from the Greek word “tribos,” meaning to rub. H. Peter Jost, the British scientist who coined the term, has estimated that friction and wear consume 2 to 6 percent of an industrialized nation’s GDP. In the United States, that amounts to hundreds of billions of dollars each year.

“Every single moving mechanical piece of equipment has sliding interfaces,” says Krick, who directs Lehigh’s Tribology Lab. “Friction and wear are the number one reason these joints, bushings and bearings give out. They also cause cars to consume more fuel than they would otherwise have to.”

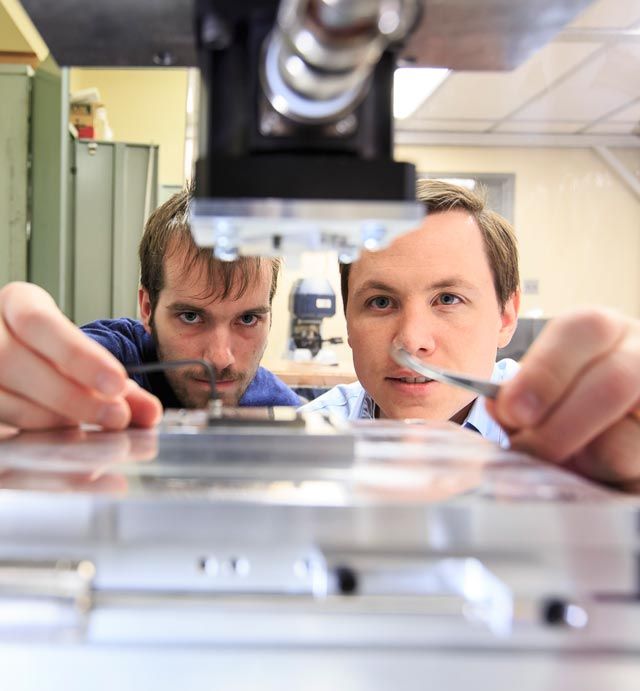

Krick and his collaborators at DuPont Inc. recently received a three-year grant to study tribology through the National Science Foundation’s Grant Opportunities for Academic Liaison with Industry (GOALI) program. Krick is principal investigator on the project, DuPont scientists Christopher Junk and Gregory Blackman are co-PIs, and Lehigh Ph.D. candidate Mark Sidebottom leads the experimental efforts. Ph.D. candidates John Curry and Guo Song Zeng work with Krick, as do several undergraduate students.

According to the NSF grant, Lehigh and DuPont will “develop and study ultralow-wear composite materials suitable for manufacturability and usage in commercial and industrial settings.”

In simple terms, the researchers are studying Teflon, the fluoropolymer coating for cookware. Teflon is cherished by consumers because it is non-adhesive and easy to clean, Krick notes, but its relatively rapid rate of wear makes it unsuitable for sliding applications and impossible to be injection-molded into desired shapes.

To overcome these limitations, Krick’s group is making nanocomposites of alumina and dispersing them as filler in the Teflon polymer matrix to modify the matrix and reduce its melting temperature. The technique was introduced by Krick’s Ph.D. thesis adviser, W. Gregory Sawyer, a professor of mechanical and aerospace engineering at the University of Florida.

The alumina nanocomposites, says Krick, interact synergistically with the Teflon polymer to facilitate chemical, physical and mechanical changes that reinforce the surface and improve wear resistance.

Krick’s group is working with two materials produced by DuPont under the Teflon brand name—PTFE (polytetrafluoroethylene) and PFA (perfluoroalkoxy), a copolymer resin that can be inject-molded.

“DuPont has been working on this problem for many years,” he says. “They have improved Teflon so it can be injection-molded but not for low-wear materials. We want to build on this to make Teflon wear-resistant and injection-moldable for both low-wear and longer-lasting materials.”

In the Lehigh Tribology Lab, Krick’s students examine the origins of friction, wear, materials deformation and adhesion on complex surfaces ranging from cells to nanocomposites and in environments ranging from the vacuum conditions of outer space to thousands of feet under water. They conduct sliding experiments that can remove, on average, less than 1 angstrom of material per sliding pass, as well as larger amounts. To measure friction and wear, the students design and build tribometers, while also using chemical analysis techniques such as infrared spectroscopy and X-ray photoelectron spectroscopy. The lab also houses an optical profilometer that measures surface profiles in 3D at the nanoscale.

“We have been able to reduce the wear rate for Teflon by 10,000 times for sliding applications,” says Krick. “This is potentially game-changing. Typically, industry has to replace worn-out parts too often. They end up in landfills. We can cut costs and reduce this waste.”

Recently, Krick’s group sent samples to the International Space Station, and its tribometers became the first to be directly exposed to the Low Earth Orbit Environment.

Tribology, says Krick, overlaps with physics, mechanics, chemistry, materials science and many more fields.

“This is really fun work,” he says, “if you like learning something new every day. We work with a very interdisciplinary team at DuPont—fluorine chemists, polymer physicists, materials scientists, chemical engineers, everything.”

His colleagues at DuPont share his enthusiasm.

“This project will focus on very fundamental questions, but with real applications in mind,” say Junk and Blackman.

Krick’s work in tribology also intersects with biology. In a collaboration with Gregory M. Erickson, professor of anatomy and vertebrate paleobiology at Florida State University, Krick and his students are studying the surfaces of teeth estimated to be 66 million years old that were recovered from the fossils of Triceratops, a three-horned dinosaur that lived in the Late Cretaceous period.

The group has discovered that Triceratops’ teeth were composed of five different tissues—one more than the teeth of horses and bison and three more than those of crocodiles and other reptiles. The arrangement of the tissues within the tooth controlled its functions; each tissue of the animal’s teeth wore at varying rates, creating a morphology of “peaks and valleys” that enabled the dinosaur to slice and grind its food and thus consume a wider variety of plants.

“We think that as Triceratops chewed plants, the enamel maintained its surface while the materials with less wear-resistant features receded,” says Krick. “The result of this uneven wearing was a tooth with an outer-edge that could slice and grind at the same time.

“The relative wear rates of the teeth provide information about the evolution of the dinosaurs, what they ate, and how the variation in tooth structures (ridges, peaks, valleys) caused by the difference in material properties allowed the animals to eat a more varied diet and, possibly, to improve their health.”

Scientists from the University of Pennsylvania and the American Museum of Natural History are collaborating on the Triceratops project.

The researchers published their findings in June in the journal Science Advances.

Natasha Vermaak, an assistant professor of mechanical engineering and mechanics at Lehigh, and Krick have paired up to extend this wear model developed for dinosaur teeth to the engineering of material systems.