Fatigue, says Jesse Nawrocki, can set in quickly for a surgeon performing a heartbypass operation. The same hardened arteries that necessitate the surgery put a surgeon’s suturing skills to the test.

“The blood vessels of heart-bypass patients are often calcified because of poor health and age,” says Nawrocki, who earned his Ph.D. in materials science and engineering from Lehigh in 2001 and is now a staff engineer at Ethicon, a division of Johnson & Johnson.

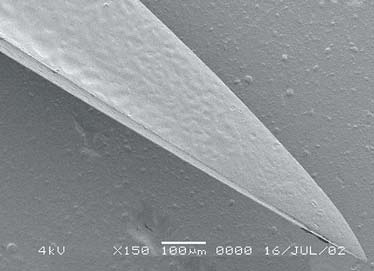

“This calcification gives arteries an eggshell-like hardness and causes the coatings on the surgical needle, which is only about eight one-thousandths of an inch in diameter, to wear off very easily.

“During suturing, the needle has to be passed by hand 10 to 20 times through the two blood vessels around the circumference. Because of the calcification, the needle frequently feels dull and needs to be replaced, which increases the procedure time.”

Nawrocki has developed a new coating that enables surgeons to do all bypass suturing with just one needle. His “MultiPass Needle Coating Technology” has been patented and is used on premium plastic surgery and cardiovascular surgery needles.

For his invention, Nawrocki received the Johnson Medal, the most prestigious award given by Johnson & Johnson.

“Jesse’s invention,” said an article published by Johnson & Johnson, “has afforded surgeons unparalleled control, flexibility and comfort during [surgeries] by allowing far greater numbers of passes through tissue with little diminishment of lubricity.” Like previous needle coatings, Nawrocki’s is silicone-based. But it also contains polyolefin waxes, which give it the lubricity and the durability required for suturing.

The coating owes its success, says Nawrocki, to its material and its processing.

“I tried first to understand why previous coatings did not work. I didn’t think lubricity and durability could be accomplished with just silicone chemistry. I decided to go with a composite material, which gives you a combination of properties. We were able to keep the lubricity of silicone and gain the durability of a composite material.”