Brandon Krick says he’s had the good fortune to research space and dinosaurs—“all the things you want to explore as a kid,” he says. But his real passion is the science of tribology, “which few people have ever heard of,” he says.

For Krick, assistant professor of mechanical engineering and mechanics, tribology—the study of study friction, wear, and lubrication has long been as fascinating as any sci-fi-movie mainstay. Derived from the Greek tribos, meaning “to rub,” tribology is the study of interactive surfaces in motion. Its foundations as a distinct scientific discipline are relatively recent. But uses for tribology are simultaneously at the leading edge of materials science and older than technology itself. Grinding a stone ax to a sharp edge involves tribology. So does developing materials that allow an instrument array on a satellite to slide open in low-earth orbit—and so does discovering prehistoric teeth that can slice and grind at the same time.

He points to the namesake product of WD-40 Company as an example of his fascination with tribology. “WD-40 was developed 60 years ago as a corrosion inhibitor for the rocket industry and is now a spray lubricant in everyone’s garage,” Krick says. “Yet it hasn’t been clear how the ingredients in WD-40 interact to produce its performance.” Krick, with students Mike Goldstein and Jacob Smith, is working with the company to analyze how the elements in this compound come together to produce its properties, in hopes of enhancing the formulation.

Understanding the fundamental science of friction and wear has vastly more significance than silencing a squeaky door hinge. Developed countries lose an estimated 2 to 7 percent of GDP to costs associated with friction and wear, including energy loss and replacement of worn-out machinery. “The toll is approaching a trillion dollars in the U.S. alone,” Krick says. “You need friction or you wouldn’t have any grip or be able to react to force. But we need to be able to predict, control and in many cases reduce friction and wear, and that will lead to new materials and devices.”

Doing so is inherently interdisciplinary. “The frontiers of tribology research involve interfaces of disciplines as well as materials,” Krick says. “You have to think about chemistry, physics and mechanics all being involved. It’s a very collaborative field.”

Interdisciplinary collaboration helped launch Krick’s research career as a graduate student at the University of Florida. Together with his Ph.D. advisor Greg Sawyer and Florida State paleobiologist Gregory Erickson, Krick discovered that plant-eating, duck-billed hadrosaurs had complex dental batteries consisting of multiple materials with different wear rates—a versatile system different from that of humans and animals. Krick and his team have continued working with fossils at Lehigh University, demonstrating that the three-horned triceratops had complex dentition with additional features more complex than any reptile or mammal now alive.

Implications go beyond understanding what animals ate during the late Cretaceous period. Krick and his students Tomas Grejtak and Mark Sidebottom, working with Natasha Vermaak, Lehigh assistant professor of mechanical engineering and mechanics, and her student Xiu Jia, are using the computational model Krick developed to explain—and reveal—tissue structure in prehistoric animals in order to optimize modern composite materials.

"If you understand how material properties affect global properties of a system, you can design something that has a low wear rate or lower frictional force or electrical conductivity and optimize for multiple properties simultaneously,” Krick says. As with dinosaurs, “composites allow you to take material A that’s good at one thing and material B that’s good at another and put them together to make a material that’s good at both.” The National Science Foundation has awarded a three-year grant for the team’s work on topology optimization for wear of composite materials.

Krick’s interest in composites dates to his Ph.D. thesis on polymer composites such as Teflon, a fluoropolymer that famously has non-adhesive properties but also a high wear rate. Krick and his group have found that dispersing nanocomposites of alumina as filler can make Teflon 1,000 to 10,000 times more wear resistant. “That opens up a lot of new design paradigms,” Krick says. He, Sidebottom and Lehigh research scientist Chris Junk are partnering with Greg Blackman and Heidi Burch of DuPont, and are now midway through a three-year NSF grant to explore the use of injection-moldable ultralow-wear fluoropolymers in sustainable sliding applications.

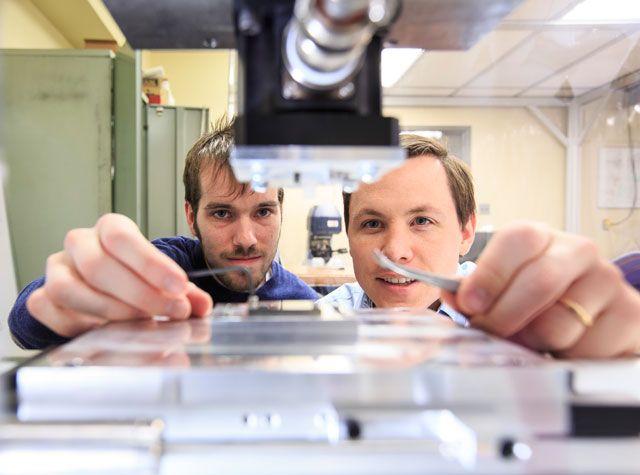

Space is an area of active interest in low-wear sliding materials. In low-earth orbit, multimillion-dollar instruments often depend on precise and reliable sliding interfaces to deploy in an extremely harsh and corrosive environment. Krick and colleagues at the Air Force Research Laboratory and University of Florida designed the first tribology experiments conducted in low-earth orbit environment, on the International Space Station. Now, using Lehigh instruments such as the HS-LEIS (high-sensitivity low-energy ion-scattering spectrometer), Krick’s student John Curry is analyzing samples of materials like molybdenum disulfide that were exposed to atomic oxygen, a damaging chemical in the low-earth environment outside the ISS.

Analysis at the nanoscale can produce surprising results. Working with professor Nelson Tansu and his Ph.D. student Guosong Zeng in Lehigh’s Center for Photonics and Nanoelectronics, Krick has discovered that gallium nitride—well known for its electronic and optical properties—also has ultralow-wear properties akin to diamonds. “This will have huge ramifications for device design,” Krick says.

Yet the tribology of soft materials can be just as important as that of hard ones, especially in biological and biomedical research. “With the exception of teeth, tissues in contact with each other throughout the body tend to be soft,” Krick says. “The importance of surfaces interacting at the cellular level makes biomedical research a promising field for tribologists.” His lab has developed tools that measures loads, pressures, sliding velocities and other factors related to interfaces with materials such as biocompatible hydrogels. Krick is convinced that the next major impact of tribological sciences will be in the biomedicine and health.

Lehigh is well suited for this interdisciplinary range of projects, says Krick, who previously worked with large state universities where collaboration between departments was more challenging. “We have unique facilities, curious and engaged students, and a very favorable size in that we’re both large and small enough that we can easily interact across departments,” he says. “There are very low barriers to collaboration.”