Interviews by Christine Fennessy and Mary Ellen Alu

NASA’s James Webb Space Telescope—hailed as the most complex space exploration project in human history—is expected to be fully operational in June. Webb will begin a new era in astronomy, capturing photons that are 13.5 billion years old and allowing scientists to study the earliest stars and galaxies. Those behind the scenes, including electrical engineering alum Scott Willoughby ’89, vice president and program manager for the JWST at Northrop Grumman, have pushed the boundaries of possibility.

Willoughby spent the past 12 years leading the interdisciplinary team that designed, built, tested, and deployed the infrared observatory (which was packaged like origami for its million-mile journey).

"The hardest part is not actually surviving space," Willoughby says, "it’s testing on the ground to make sure you didn’t fool yourself into thinking it was going to work in space. And, I’m proud to say, the team just nailed it."

|

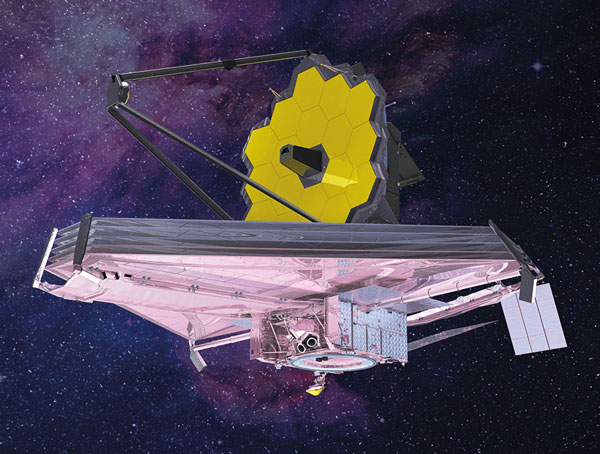

Folded for launch, Webb was rocketed into space on Dec. 25, 2021, and successfully deployed (artist’s depiction) over a two-week period. |

Q: What are the mission’s ultimate goals and why do they matter?

A: We want to answer questions: Where did we come from and are we alone?

We want to know how the elements in the periodic table formed. It may give us an understanding of how our own planet and star are evolving. Webb will also train our eye on planets that are closer to us—only millions of light years away. And it will look at those planets to see if they have an atmosphere around them that could be Earth-like, meaning it may support life like ours. Everybody wants to know: Is there life out there in the universe? Are we this one-of-a-kind pale blue dot where magic occurred, or is there something there and we just don’t know it yet?

Q: Webb is considered the successor to the Hubble Space Telescope, but it looks completely different. Why is that?

A: When you look at Webb, you might think the engineers were artists, but the design is functional. Webb’s optic is so big—seven times bigger than Hubble’s—that we couldn’t put it in a can. It’s this beautiful set of 18 hexagonal segments that are coated in a thin layer of gold, because gold reflects infrared. It’s a giant mirror that’s 22 feet in diameter. Huge. Bigger than the top of the rocket, meaning it had to be folded.

Every object confesses its heat in the infrared spectrum. It’s why night vision goggles work. Webb not only has to find this very faint light, but has to find it where every other thing in the universe is in our optic with infrared heat wavelengths. So we have to be colder than what we’re looking for.

One of the things that makes Webb unique from Hubble is, on orbit, we’re going to run our optics at -400°F. That’s an engineering marvel to design something to survive cryogenic temperatures. To create that thermal condition, we have to block the close infrared light, which is our own planet, our moon, and our sun. To do that, we deploy a diamond-shaped sun shield, the size of a tennis court, that’s coated in aluminum.

Q: What was the hardest problem to solve?

Q: What was the hardest problem to solve?

A: The number one challenge was that we had to build a telescope bigger than could fit on the top of the rocket. To get out of Earth’s atmosphere safely, you have to be protected in a payload fairing. And that fairing, for decades, has been 5 meters in diameter. Webb’s optic is 6 ½ meters in diameter. So we had to build it in segments that can be folded back and then deployed on orbit. And that giant sun shield…it had to be folded like a parachute.

Never in the history of humankind has an invention had to go into space, and have to get built up as it traveled. It was amazing how flawless that went. But it took us 20 years to make that work.

On the ground, we had to simulate space. We had to off-load gravity with an incredible amount of mechanisms that counterbalanced it—we either hung [Webb] from the ceiling or pushed it from below with just slightly enough force to trick gravity, but not over trick it. We had to put it in a vacuum chamber and simulate thermal conditions.

Q: Webb was designed with 344 “single-point failures.” What did that mean?

A: It meant a lot of stressful days on the ground, making sure they worked. Not all of them meant end of mission, but many of them did.

There’s never been something built that had that many single-point failures and that level of testing to prove they’re working. You don’t test something to what it needs to do on orbit. If it needs to be strong, you design it to be sometimes two times stronger. If it needs to work at -380°F, we test it at -400°F.

We had an entire plan if our solar array didn’t deploy. They gave them cute names—we had the shimmy and the shake, we had the twirl, and the fire and the ice. If something stuck, what if I change the sun angle and make it either expand or contract? Maybe that will release it. What if I fire my thrusters and shake it a little? Turned out, we didn’t need any of those, but I had a team that spent years coming up with contingency operations.

And there was the comment, well, if it went so perfectly, was it ever really as hard as you said it was going to be? [laughs] It was like, yes, what we did was hard on the ground. The tests we did had to confess every weakness to us, even weaknesses that probably would’ve never been an issue on orbit. We corrected those also. You can’t take a chance.

Q: Has the project spawned any new technologies?

A: Each of Webb’s mirrors has a surface figure accuracy (meaning how well they represent the intended concave shape) that’s better than 20 nanometers. To put that in perspective, what if I gave you the job to perfectly flatten out the US? Get rid of the Appalachians and the Rockies and fill in the Grand Canyon. Your error bar could only be about 3 inches across the entire 2,500 miles from California to New York.

How do I prove that the surface of this mirror really is that good? We use the speed of light to our advantage with laser interferometry. I bounce light off of a spot on the mirror. And depending on how long it took for the light to return, I know how far it traveled. So if there was a little dip in that mirror, it would have to travel just a little bit further and then come back to me.

How do I prove that the surface of this mirror really is that good? We use the speed of light to our advantage with laser interferometry. I bounce light off of a spot on the mirror. And depending on how long it took for the light to return, I know how far it traveled. So if there was a little dip in that mirror, it would have to travel just a little bit further and then come back to me.

NASA and Northrop came up with such a precise technique to test these mirrors that ophthalmologists now use that to measure your eyes when you go in for LASIK or they need to know the shape of your eye and understand the curvature.

And it isn’t just the testing techniques. Now that we’ve proven we can build something bigger than the top of the rocket, we’ve built a new “set of shoulders” for the next decades of observatories. The bigger the mirror, the more light you collect, the more sensitive the observatory. Now that we’ve built a mirror bigger than the top of the rocket, the appetite will never be sated again with something that fits inside.

Q: What can aspiring engineers take away from your experience?

A: As an engineer, everybody is focused on what product they’re going to design, right? You want to make the next greatest thing—the next electric car, the next spacecraft. But there are other incredible roles. I consider myself more of a test person than a design-for-engineering person. I use my engineering knowledge in what’s called “integration and test,” and the jobs of the folks who have to solve the problem of how to prove something works are every bit as complex and valued as the people who create the product itself. And there’s a tremendous need to do that. In the end, team success is a very powerful feeling.