He’s a self-described “computer nerd” who loves the computational side of research.

He’s a self-described “computer nerd” who loves the computational side of research.

And now, Peter Schwarzenberg ’16 gets to put his nerd skills to work in a country renowned for research into orthopaedic trauma.

Schwarzenberg, a third-year PhD student in mechanical engineering, was one of just 10 students selected from across the country for the Institute of International Education’s Graduate International Research Experiences (IIE-GIRE) program.

As a grantee, Schwarzenberg is spending six months in Switzerland at the University of Zurich’s Musculoskeletal Research Unit (MSRU) developing new mechanical models for callus, the bony tissue that forms during fracture healing.

The IIE-GIRE is a new program funded by the National Science Foundation. Its goal, according to its website, is to “support U.S. engineering graduate students and their academic advisors, for graduate student research experiences abroad.”

Grantees in this first cohort of the program received funding for up to six months to conduct innovative research and promote meaningful connections between their home and host institutions. Stipends are provided for travel, living expenses, health insurance, visa fees, and educational materials. Each student’s advisor also receives $2000 for travel to the host institution or to support similar international endeavors in their home campus graduate programs.

A telling twist

Most people who break their tibia, or shin bone, proceed along a normal healing timeline. As the weeks go by, more and more new bone called callus forms along the fracture line.

But some people do not heal normally. This failure to heal is called a nonunion, and it can be utterly debilitating. The problem, however, is that surgeons typically rely on X-rays to determine the cause of a nonunion. But X-rays are two-dimensional and often fuzzy, and they may provide an incomplete picture if something is blocking the problem area.

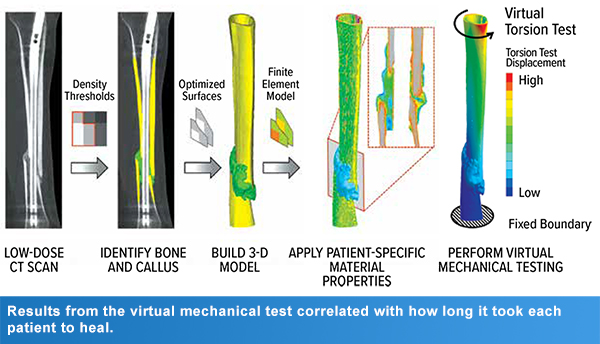

Schwarzenberg and his PhD advisor, Hannah Dailey, an assistant professor of mechanical engineering and mechanics, recently published two papers describing how they’ve used virtual structural analysis of low-dose computerized tomography (CT) scans to predict healing in tibial fractures.

Using specialized, commercially available software on the CT scans of patients with lower leg breaks, Schwarzenberg built 3-D mechanical structural models that identified the different regions of both the bone and the new bone, or callus. He ran those models through finite element analysis software, and then he and Dailey simulated fixing the bottom of the bone and putting a load on the top of the bone in the form of a one-degree rotational twist. The technique is known as a virtual torsion test.

The test revealed how much the bone flexed when it was twisted. The stiffer a bone was early in the healing process, the quicker the patient could bear weight.

In the end, Schwarzenberg and Dailey found that the virtual mechanical test could accurately predict how long it would take a patient to heal. Currently, there are no other tools that can do that. If a patient isn’t healing, it’s an educated guessing game on the surgeon’s part as to why that is, how long the healing process might take — if it takes place at all — and whether to wait or intervene surgically.

In the end, Schwarzenberg and Dailey found that the virtual mechanical test could accurately predict how long it would take a patient to heal. Currently, there are no other tools that can do that. If a patient isn’t healing, it’s an educated guessing game on the surgeon’s part as to why that is, how long the healing process might take — if it takes place at all — and whether to wait or intervene surgically.

The pair’s ultimate goal is to produce a diagnostic test that can help surgeons determine if an additional operation is necessary.

Characterizing callus

“There’s one big flaw in our experimental design,” says Schwarzenberg. “There’s a lot of data in the literature for the mechanical properties of bone. It’s easy to get cadaver bones. It’s next to impossible to get cadaver bones with callus. Bone is this nice, organized, hard structure, and callus is almost like cartilage, kind of soft. It remodels into bone, but at the time points we’re looking at, we don’t expect the callus to have the same underlying structure as bone. We think we’re making it too strong—closer to bone than it should be—because we’re using a model that was developed from only bone. So every time we present somewhere, someone in the audience shoots up their hand, and says, ‘Isn’t callus completely different than bone?’ So our goal is to characterize that callus.”

And that is exactly what he’s doing as a 2019 IIE-GIRE fellow at the University of Zurich.

Now at the MSRU, Schwarzenberg is combining his and Dailey’s virtual technique with an optimization algorithm to refine their understanding of the mechanical properties of callus.

Schwarzenberg says he’s proud of landing the fellowship. He’s flattered that he’s one of just 10 recipients. But he is convinced that such recognition hinges on the fact that very high level research is being conducted every day at Lehigh, and specifically, in Dailey’s lab.

“We’re doing world-class research here,” he says. “We’re working with a world-class animal research institute in Switzerland, and making a difference with what they’re doing. We’re very new, but we’re turning heads at conferences, and we’re butting heads with the big dogs.”