Fold up your laptop. Put down your PDA. Be careful – their state-of-the-art display is encased in a glass substrate that might break if you make a hasty move. But what if your profession or pastime doesn’t let you pamper your electronic gadgets?

What if you’re a soldier tracking terrorists or a jogger monitoring blood pressure? Or an engineer fitting a space shuttle with sensors?

Is it too much to ask for electronics that conform to your needs instead of requiring you to conform to theirs?

Not at all, says Miltos Hatalis, professor of electrical and computer engineering and pioneer in the field of flexible displays.

Hatalis concedes that glass-substrate technology has had its benefits, giving us PDAs and laptops, as well as PCs, high-definition TVs and other devices with images generated typically by liquid-crystal displays (LCDs).

But after fabricating electronics on glass for 15 years, Hatalis began in the late 1990s to pursue flexible displays on metal foils.

Now he is seeking to mount your big-screen HDTV on a flexible metal-foil substrate that can be rolled up and stored in a tube when it is not being used. He believes soldiers and rescue workers will soon scout unfamiliar terrain with interactive electronic maps displayed on flexible displays mounted on their uniforms.

And he envisions the day when paper-thin sheets of sensors, wrapped “conformally” around the fuselage and wings of an aircraft, give engineers a more complete picture of fatigue cracks as they develop.

Hatalis and his group in Lehigh’s Display Research Laboratory have moved to the forefront of metal-foil research. In 1999, they demonstrated the first transistors on metal foils, and in 2003, they fabricated the first high-performance circuits on foils. In 2006, they placed a 3.3-inch diagonal display of 330,000 pixels, each containing two transistors, on a 6-inch stainless-steel wafer. The group has received funding from DARPA, the U.S. Display Consortium, the Army Research Laboratory and Lehigh’s Center for Optical Technologies. It enjoys logistical and financial support from Lehigh’s Sherman Fairchild Center for Solid State Studies.

Beyond the OLED wave

As the electronics world prepares to advance from LCD to OLED (organic light-emitting diode) technology, Hatalis is looking farther into the future.

This year, Sony plans to introduce the first OLED TV. In two years, analysts predict, the market for the new TVs could exceed $1 billion. The market for all OLED displays – signs, TVs, computers, laptops and handheld devices – is expected to approach $11 billion by 2012.

OLED displays, whose thin organic films emit light when an electrical current flows through them, promise one day to be thinner, less power-hungry, simpler and cheaper to manufacture than LCD displays. Both technologies rely on thin-film transistors and both, for the time being, are housed on glass substrates.

This is where Hatalis’s group comes in.

“We believe we are one step ahead,” says Hatalis. “We’re taking the thin-film transistor (TFT) technology that enables big-screen TVs, cell phones, MP3s, etc., and we’re importing it from glass onto flexible substrates.

“Flexible displays are thinner, lighter and more conformal than glass displays. Glass can be used only for flat rigid displays. Flexible displays are virtually unbreakable. They can be folded or held like a newspaper. And flexible OLED displays consume less power than LCD displays.”

Flexible display researchers form two camps, says Hatalis – those who work with plastic substrates and those who work with metal foils.

Metal foils offer several advantages over plastic, or polymer substrates, says Hatalis. Because metal can withstand much higher temperatures, it is easier to fabricate electronics, especially high-performance electronics, on metal foils than it is on plastics. Metal foils are compatible with most wet-chemistry processes, and their resistance to moisture makes them ideal for OLEDs.

In addition, metal-foil substrates can accommodate more components, such as display drivers. This improves reliability and adds functionality, thus eliminating the need for extra electronics.

The superior thermal properties of metals, says Hatalis, make them amenable to the polysilicon TFT technology that his group uses. Most metalfoil researchers work with amorphous silicon TFT technology, says Hatalis, but poly-Si TFT offers higher current and faster switching speed.

“For flexible displays, poly-Si TFTs can be used for both pixel-switching and integrated display-driver circuitry,” Hatalis wrote in an article published late last year in Applied Physics Letters. “Such integration not only increases the system’s reliability but also reduces the physical size of the flexible display.”

A full-service shop

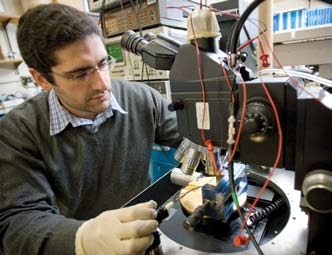

Inside the Display Research Lab, Hatalis’s team designs, fabricates, characterizes and tests electronic circuitry as well as display and sensor systems on metal-foil substrates.

“We have a unique infrastructure for building prototypes,” says Hatalis. “We design, fabricate and test all of our systems. We have demonstrated fully functional systems for both displays and sensors. Only a handful of labs worldwide have this capability.”

“We work beyond R&D to make a prototype system,” says Abbas Jamshidi-Roudbari, a graduate student who joined Hatalis’s team in 2003. “That’s why government agencies and industry are asking us to develop new electronic systems on stainless-steel substrates. We can do flexible circuitry and systems on a stainless-steel substrate only 100 microns thick.”

Hatalis’s group orders high-precision thin foils and photolithographic masks from outside vendors. Everything else is done in house.

The group has overcome several challenges posed by metal foils. These include the inherent roughness of stainless steel as well as changes in the microstructure caused by grain growth during annealing, or heating.

“Commercially available metal foils are very rough,” says Hatalis. “Any surface bump greater than 3 nm in dimension can cause an electrical short. We have learned to smooth the surface by polishing it and coating it with an insulating layer.

“Also, because the foil is not rigid, it presents issues during annealing, cleaning, lithography and other stages of fabrication. We have learned how best to handle the metal-foil substrate during processing.”

“There have been extensive studies of amorphous silicon TFTs on flexible substrates under mechanical strain,” Hatalis’s group reported last year in the Applied Physics Letters article. “However, no relevant investigation was reported for poly-Si TFTs in the past.”

In the article, the group reported that high-performance circuitry could be bent to a 1-cm radius of curvature and function without problems. At that radius, “all TFTs remained functional under strain applied up to 1.13% with no obvious physical damage observed. This shows that the poly-Si TFT technology on stainless steel foil is suitable for flexible electronics applications.”

Dreaming big

What will those applications be?

“In the next five to 10 years,” says Hatalis, “we can expect to see cell phones and other electronic gadgets no thicker than credit cards. Some iPods are this way already.

“Some companies have demonstrated prototype displays that unroll out of a box. We think we can also integrate flexible displays onto clothing, such as soldiers’ uniforms, and onto backpacks.

“In the movie Red Planet, three astronauts on Mars are shown rolling out a display of the Martian horizon to help them determine where they are. This kind of technology is not yet in electronics stores but it’s coming.

“Wherever people need to access visual information quickly, on unbreakable electronic systems that are easy to carry, flexible displays are going to make a big difference.”

Flexible electronics will also find biomedical applications.

Hatalis is collaborating with Lehigh chemistry professor Kamil Klier and Robert Dorner of the Royal Institution of Great Britain on a new generation of TFTs made from chalcogenide semiconducting materials.

“Based on our technology, we believe it would be possible to develop a disposable ‘computer patch’ that could monitor basic physiological functions. In just one example, the patch could be used to monitor babies and avoid sudden infant death syndrome.”