A major roadblock to computational design of high-entropy alloys has been removed, according to engineers from the Ames Laboratory at Iowa State University and the Rossin College, thanks to an enhanced algorithm that radically reduces the search time used for predictive design.

A major roadblock to computational design of high-entropy alloys has been removed, according to engineers from the Ames Laboratory at Iowa State University and the Rossin College, thanks to an enhanced algorithm that radically reduces the search time used for predictive design.

Existing tools for creating random distribution of atoms in materials simulation models are resource intensive, outdated, and limited in their reach for fast model generation, says Ganesh Balasubramanian, an associate professor of mechanical engineering and mechanics at Lehigh. And, even with supercomputing advances, he explains, the time required to generate robust models for materials simulations is prohibitively long.

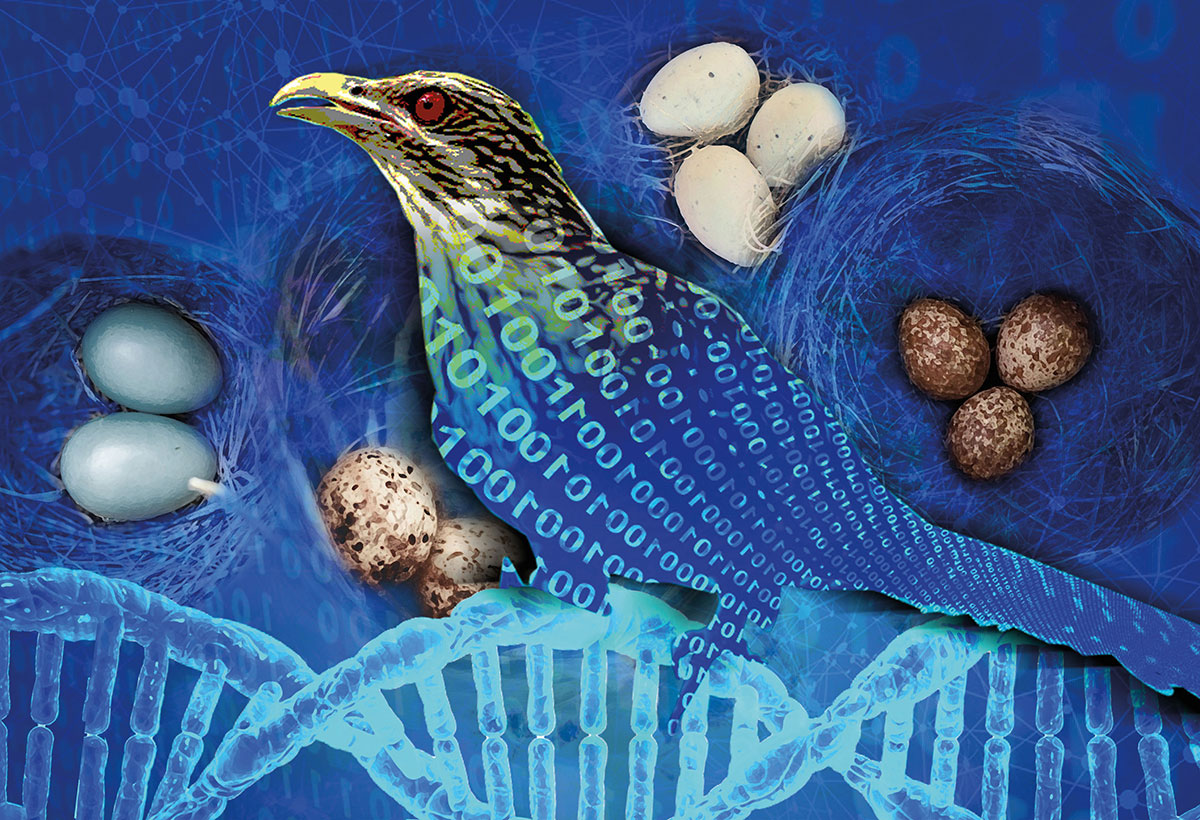

The team’s goal was to accelerate the computational modeling of complex alloys. They did this by developing a hybrid version of an algorithm called the Cuckoo Search (inspired by the evolutionary strategy of Cuckoo birds) to find the most viable “egg,” or solution, within a huge set of possibilities.

“The speed up to solution time was not surprising, but the factor reduction in time—13,000-fold—was indeed startling,” says Balasubramanian. “What took about a day to accomplish, can now be done in seconds. This tool also enables creation of physically realizable systems that now can be directly compared against experimental samples.”

The research, which is supported by the Department of Energy and the National Science Foundation, is described in a paper recently published in Nature Computational Science.

High-entropy alloys are formed by mixing equal or relatively large proportions of five or more elements. Balasubramanian works specifically with multi-principal element alloys, which are formed by mixing significant and varying proportions of multiple elements.

Preliminary studies have shown that multi-principal element alloys have superior mechanical strength and hardness, making them ideal as a protective coating on turbine blades, medical implants, ship surfaces, and aerospace parts.

“The purpose of our work on this was to optimize alloy design and, due to the results, we hope it will change design practices in materials for the better,” Balasubramanian says. The computational tool may also have applications in any field that requires optimization, he adds, including stock markets, commerce, and engineering systems design.

CREDIT: Illustration, Ames Laboratory/U.S. Department of Energy