Special report by Christine Fennessy

Climate change may be the most complex and multifaceted problem of them all.

It is forcing engineers to solve for the unknown in terms of the extent, severity, and duration of the economic and social fallout from a warming world. It requires the kind of teamwork and collaboration that inspires and fosters out-of-the-box thinking. And it demands boundless creativity and persistence to develop the alternatives that can fuel our lifestyles without contributing to the emissions and waste that currently threatens them.

Climate change is a problem suited for the engineers in the Rossin College, where talented faculty and students are working across disciplines to conceptualize smart transportation systems that will reduce pollution and make communities more livable. They’re building models to help government and industry leaders better prepare for superstorms, fortify their infrastructure, and take measures to reduce the impact of catastrophic flooding. They’re proposing novel solutions to massive waste issues both here and abroad—contributing to the foundational research that will advance the development of more sustainable and resilient communities. Read on to learn more.

|

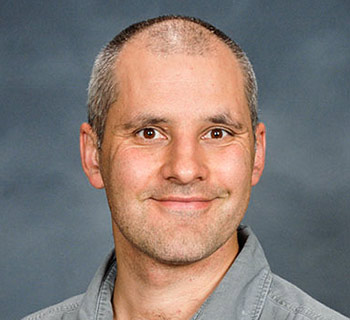

Steven McIntosh |

Researching Alternatives: Solar hydrogen fuel

It’s long been known that photocatalysts can capture sunlight, split water into hydrogen and oxygen, and generate hydrogen fuel. When hydrogen is used as a fuel, either on its own or to generate electricity, it emits no greenhouse gases. Only water vapor and warm air.

But, generally speaking, growing the materials that compose those catalysts is a chemically harsh process. They’re typically grown at high temperatures using organic solvents—highly toxic, carbon-based substances that are known neurotoxins and carcinogens.

“There are a lot of developments and breakthroughs in the field of renewable energy,” says Steven McIntosh, a professor of chemical and biomolecular engineering and associate director of Lehigh’s Institute for Functional Materials and Devices (I-FMD). “It’s great to invent something in the lab and have a sample of what it could possibly do. But if there are fundamental barriers to creating the enormous scale we need when it comes to clean energy generation, then that development will not lead to a cleaner environment.”

The use, accumulation, and recovery of those nasty organic solvents are one such fundamental barrier. So several years ago, McIntosh and his research team set out to determine if functional catalytic materials could be created without the harmful chemical processing. If, in fact, they could harness and control the biological system that living organisms use to form hard materials like bones, teeth, and shells, to make these catalysts. A process that occurs at room temperature, in water, and using abundant inorganic materials. A process that is environmentally friendly, and thus, potentially scalable.

It worked. The team was able to create the catalytic materials in the lab using this green process.

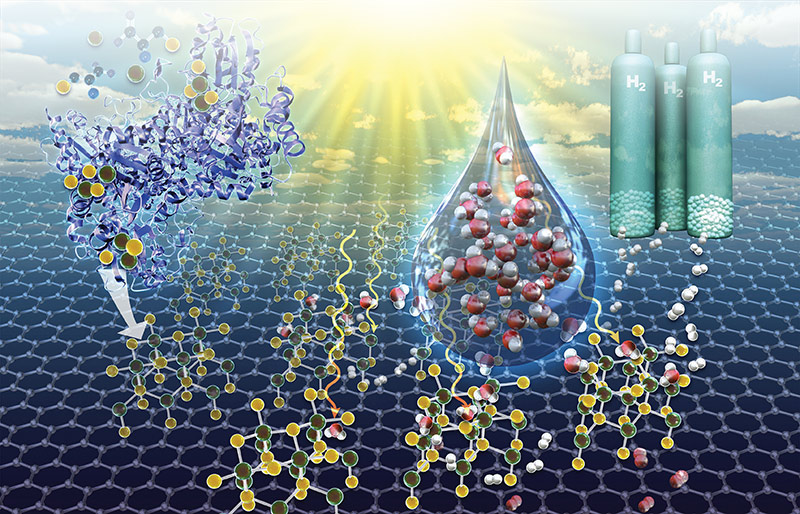

“Since then, we’ve worked to demonstrate that the materials can perform the function that we want,” says McIntosh. “The materials we make are classified as quantum confined nanoparticles [or dots], and they can be used in many applications, such as cancer biomarkers. In our most recent paper, we were able to show that you could split water with these. We also found that we can make another component, a sheet of reduced graphene oxide, through the same process we made the dots. When you put the quantum dots and the graphene together, you make a much stronger catalyst. Many people have the same structure, but our work was featured on the cover of Green Chemistry because we’re doing it in a green way. With that, in my mind, one huge barrier to scale went down.”

|

Illustration: Courtesy of Green Chemistry |

Toppling those barriers one by one is essential. In the United States, hydrogen is used for refining petroleum, making fertilizer, treating metals, and processing foods—all giant industrial processes that consume huge quantities of hydrogen at enormous environmental cost.

“Right now, for every two or so hydrogen molecules you make, you emit at least one carbon dioxide molecule” says McIntosh.

A greener process—coupled with a virtually inexhaustible supply of sunlight and water—would also have a huge impact on the use of hydrogen as a carbon-free fuel source, he says. Hydrogen could be used in fuel cells, or could be burned to make electricity.

“Think about it,” says McIntosh. “What is a fuel? It’s just a way to carry energy. And currently we carry energy in carbon-based fuels, such as coal, oil, and gas. Hydrogen and electrons are also energy carriers, and between the two of them, you can satisfy much of the world’s energy demand. To date, the problem with scaling the use of hydrogen has been the amount of waste and the cost of being able to make these catalytic materials. But we know that, compared to the literature, we are approaching the rates and efficiency of hydrogen generation at large scale, and doing it in a cheaper, greener, more scalable way.”

His team has another paper on deck that will show how they’ve made the bonding process of the quantum dots and the graphene even more efficient. And while his favorite vision is “swimming pools full” of these catalytic materials, he’s thinking deeply about what it could mean to live in a world where houses might sport roofs of hydrogen-generating cells, where one household might generate more than it needs, and the sharing economy extends to the power we use to turn our lights on. He’s part of an interdisciplinary group of researchers across the university who are collaborating on a proposal to study the societal change required to adapt to a new energy future, specifically to study how communes share their resources.

“The way we live right now is very much, my home is my castle. But that’s not going to work if we all have to generate energy together and pool energy together. So say my hydrogen tank is full, and you needed some. How do I give it to you? And would people be okay with how we manage that? The societal change around this is huge because it’s just not how we currently live. But could people really change the way they live? It’s such an intellectual challenge, and an incredible opportunity to work with colleagues across the academic spectrum. An engineer alone can’t answer that question.”

|

Photo credit: U.S. Dept of Energy/Verdant Power |

Researching Alternatives: Tidal energy

Imagine a single tidal turbine capable of powering a community of 50 to 70 homes all year long. That’s the potential of turbines being developed by Verdant Power, a New York City–based company that builds marine energy systems.

“Verdant’s turbine is a downstream turbine, which means the flow goes over the nacelle where the electronics and generator are located, before it hits the rotor blades,” says Arindam Banerjee, an associate professor of mechanical engineering and mechanics. “But as the water flows around the pylon (the tower that supports the nacelle and rotor), the flow is disturbed and creates a velocity deficit, which reduces the amount of energy that is available to the turbine. In addition, vortex shedding from the pylon introduces periodic disturbances in the flow, which is known to reduce the life of the rotor blades themselves.”

Banerjee and his team recently received a $250,000 grant from the NSF as part of the organization’s Partnerships for Innovation program to design a pylon with fairings that will reduce this disturbance.

“We’re trying to create a fairing that can steer the wake away from the rotor blade and reduce the energy loss,” says Banerjee. “Verdant’s previous design had a fairing that was essentially a straight plate, and we found through preliminary lab experiments at Lehigh that it was a poor design.”

|

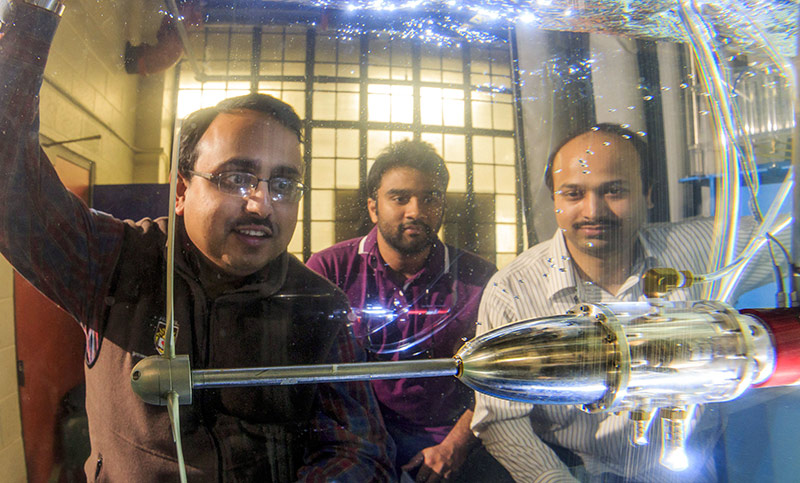

Arindam Banerjee (left) and members of his Turbulent Flow Design Group (Photo credit: Douglas Benedict/Academic Image) |

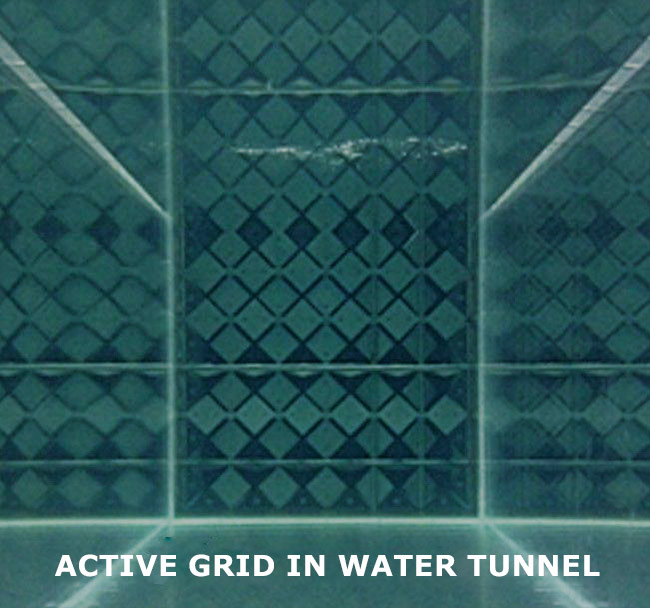

The funding will allow Banerjee and his Turbulent Flow Design Group to study different fairing shapes in a water tunnel facility in Packard Laboratory. The facility is equipped with an active grid turbulence generator, which Banerjee designed, that can mimic the free-stream turbulence that occurs in the East Channel of the East River, site of Verdant’s Roosevelt Island Tidal Energy (RITE) Project.

Banerjee and his research team will test the effect of each shape on the downstream flow at different turbulence intensity levels. “This active grid turbulence generator is a series of winglets inside a water tunnel that are placed upstream of the test section,” says Banerjee. “We operate them at a predetermined frequency, which makes them spin and create turbulence that exactly mimics what is naturally happening in the East River. The goal is to give Verdant prescriptions for the type of fairing that would be advantageous for the next generation of their turbine.”

|

The active grid turbulence generator is the first of its kind developed in an open channel/water tunnel facility. |

“By more accurately characterizing the fluid dynamics around the pylon, we believe we can make cheaper, better performing blades that will help drive the cost of these units down and make them competitive with more traditional forms of renewable energy,” says Jonathan Colby, director of technology performance at Verdant Power.

In preliminary testing, Banerjee and his students designed a double-sided fairing that they offset at an angle, or yaw, from the pylon. “We were able to cut the energy loss almost in half,” he says. Ultimately, Banerjee would like to see that loss hovering around 1 percent. Such a target would require extensive optimization, but aiming high is the point.

“We’re not going to have coal forever, we’re not going to have natural gas forever,” he says. “Renewable energy is probably going to be one of the drivers for the energy that we need to have the quality of life that we demand. We know we’re going to be successful at this, and that’s what keeps me motivated.”

Researching alternatives: Nuclear fusion

It’s hard to believe, but there is actually one initiative that currently unites the world—the quest to build a fusion reactor. The European Union, China, South Korea, Japan, India, Russia, and the United States have all committed funding and scientific resources to build ITER (Latin for “The Way”), the largest fusion reactor in history.

|

Eugenio Schuster working with graduate students |

“Almost all of us are working toward ITER,” says Eugenio Schuster, a professor of mechanical engineering and mechanics. “ITER is the mission of the majority of the fusion research groups, universities, and national labs here in the United States, and around the world.”

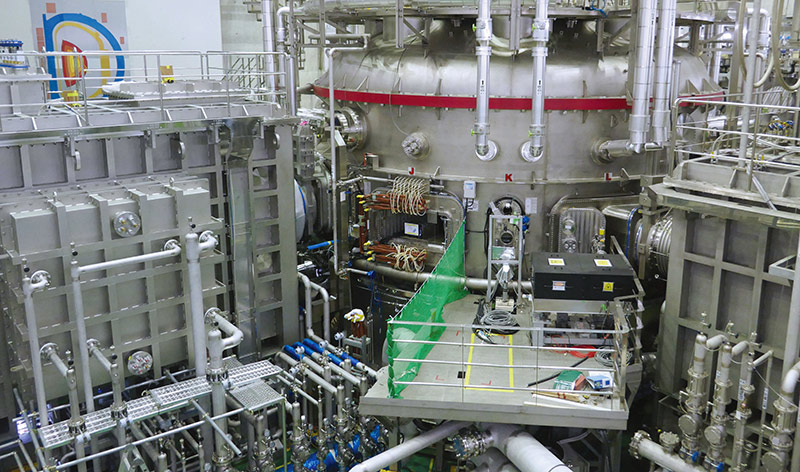

Schuster recently received two grants from the Department of Energy to help him contribute to that mission. The first supports work he and his team—the Lehigh University Plasma Control Group—will perform on the tokamak at the DIII-D National Fusion Facility in San Diego. The second supports experiments they’ll do on the EAST tokamak in Hefei, China, and on the KSTAR tokamak in Daejeon, South Korea. (A tokamak is a donut-shaped, magnetic-confinement device designed to produce fusion reactions.)

The promise of nuclear fusion is a big one. It’s often referred to as harnessing the power of the sun here on Earth, and if it can be achieved, it could provide a limitless supply of clean, safe, and reliable energy. Its abundance would stem from its fuel source—water and lithium, both of which are relatively plentiful around the world. Fusion would produce no greenhouse gases, and its waste products would have a relatively short half-life. And because fusion requires such precision for it to occur at all, the process would be safer.

“Nuclear power plants based on fission work by permanently containing the fission reaction,” says Schuster. “Once the system fails, there is an uncontrolled release of energy. In fusion, we exploit similar physics, but the process is completely different. It’s very difficult to have an accident because if anything goes wrong, the condition for fusion just disappears.”

In fact, a fusion reaction is extremely complicated to sustain, he says. “That’s why we don’t yet have a nuclear reactor based on fusion, and we’ve been working on this for more than 50 years.”

Schuster’s team tries to model the response of the “sea” of ions and electrons that is formed when two hydrogenic atoms are superheated inside the tokamak. In theory, if this plasma could be stabilized and sustained, the energy produced by fusion would create heat that would be absorbed by the reactor’s donut-shaped walls. That heat would create steam that in turn would power generators and turbines and produce electricity. Specifically, they are modeling the response of the plasma to actuators like radio frequency waves to better predict the behavior of that response, and to design control solutions to keep the plasma stable.

“In the end, everything we do and learn at DIII-D, at EAST, and at KSTAR, is so we can extrapolate it and do it on ITER,” says Schuster.

The ITER tokamak has been under construction since 2007 in southern France. It’s expected to be operational in 2025, and it will be massive. According to the ITER website, the reactor will weigh 23,000 tons (the Statue of Liberty weighs 225 tons), have a total height of 239 feet, and contain enough superconducting strands to wrap around the equator twice.

|

The KSTAR tokamak in Daejeon, South Korea |

The primary difference between ITER and all other tokamaks—other than its size—is that it will be the first nuclear reactor based on fusion.

“All tokamaks today are experimental devices,” says Schuster. “They are not generating power. They are designed to help us study the physics of the plasma, how to stabilize it, confine it, and keep it safe.”

ITER’s mission is different, he says. The goal is to produce power from fusion, specifically, to produce output at 10 times the input. But even after it’s operational, it will take ITER 10 to 15 years to get to that gain of 10, says Schuster.

“I might be retired before we have a nuclear power plant based on fusion, but I hope my students, and their students, will see it,” he says. “Nuclear fusion presents such a challenging problem to solve, but it has the potential to make a huge impact on humanity. It could solve problems around energy generation, pollution, climate change. And there is a whole cohort of Lehigh students focused on plasma control who have been contributing not only to our domestic program, but to the international program focused on ITER. It makes me very proud and excited, and it’s impossible to not want to keep moving forward.”

|

Prior research has shown Miscanthus giganteus to be suitable for the production of heat, biogas and bio-liquids. |

Researching alternatives: Biomass

A perfect world might look like a circle. A conceptual circle that begins with the sun stoking the photosynthesis that allows a crop to be frequently harvested. Such harvests could then be processed, generating energy for heat or electricity and releasing just enough carbon dioxide to feed the next field of biomass and restart the cycle.

That is, of course, not the world we live in.

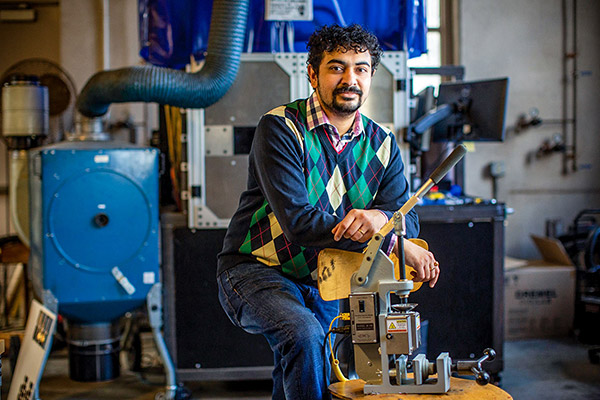

“There’s no free lunch,” says Jonas Baltrusaitis, an associate professor of chemical and biomolecular engineering. “We need to maximize our yields, and crops only grow if there are enough nutrients, which means using fertilizer. And fertilizer is hugely energy intensive to make. So at the end of the day, when it comes to using biomass as a source of energy, we’re always in the red.”

|

Jonas Baltrusaitis |

And yet, researching the potential of biomass (aka “energy crops,” plants or trees grown not as food but for combustion) as a source of renewable energy is worth the effort. That’s because biomass recycles CO₂—using it to make sugar and oxygen to grow, then releasing it when it’s burned—making it, ideally, carbon neutral. And with the ability to be harvested on a yearly basis, it’s renewable on a timescale that’s compatible with our needs. Unlike coal, methane, and oil.

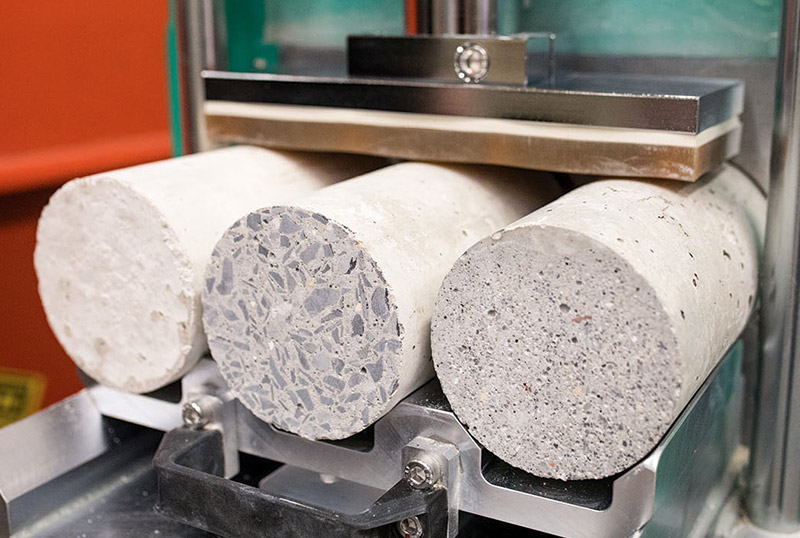

Warm climates have a somewhat easier time getting closer to this circular economy of biomass. Abundant sun and long growing seasons provide enough energy for rigorous growth. In a recent paper published in Renewable Energy, Baltrusaitis and researchers at the Lithuanian Research Centre for Agriculture and Forestry tested energy crops in Lithuania with its colder climates and shorter growing seasons.

“Countries that span Northern Europe, Scandinavia, and Russia are not known for growing things efficiently,” says Baltrusaitis. “We wanted to know if there were plant species that could adapt to these colder climates. So we planted those that are known to grow efficiently in warmer climates, and after harvesting, we evaluated their energetic potential, or how much heat per hectare or per acre they emit when burned.”

One species in particular thrived: Miscanthus giganteus. “Most of the modeling results presented in the previous research indicated that it wasn’t possible to grow Miscanthus in Lithuania because of the country’s low winter temperatures, but we found this crop to be very promising even in Northern countries,” says Vita Tilvikiene, senior researcher at the Lithuanian Research Centre for Agriculture and Forestry and lead author of the paper.

The study was an assessment of the potential of certain crops that might achieve a closer balance of energy input versus energy output. Like so many approaches to reducing climate change, utilizing biomass as a sustainable source of renewable energy is still a long way off. That virtuous energy circle will likely not happen for a long time. But it’s enough of a promise to warrant not only attention but excitement.

“Methane, gas, oil, and the technologies around those things have been around for 150 years, but biomass has really only been done at the rudimentary level. That was how my parents heated their house,” says Baltrusaitis. “It represents a very different problem of carbon dioxide capture. It is so stimulating to tackle problems that are on the global scale that haven’t been addressed yet.”

Feature Illustration Credits: Vectorpop/iStock