Experts around the globe are in a race to learn why nano-silica acts as a synergist in rubber-toughened epoxies. interest is understandable, given the new applications for structural adhesives.

Aston martin, whose high-end cars are favored by James Bond, recently switched from welding to adhesive bonding to join the major components in its new DB9 sports car. lotus is using structural adhesives with mechanical fastening techniques on its upcoming 2+2 sports car. The Ford F-150 pickup truck uses new crash-durable adhesives.

High-strength adhesives have been used in aircraft, says Ray Pearson, who directs lehigh’s Center for polymer Science and Engineering. But they were not suited for autos until recently because they were brittle in crash situations.

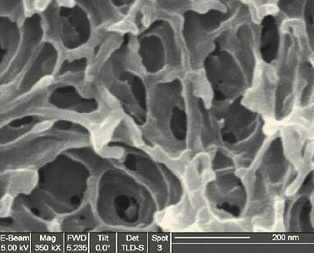

A breakthrough came when a modified epoxy that creates soft, micron-size toughening particles was combined with hard silica particles a few nanometers in size. adding the well-dispersed nano-silica to rubbertoughened epoxy enhanced its toughness, enabling it to resist fracturing and to dissipate mechanical energy at a crack tip.

Pearson’s group identifies and models toughening mechanisms in epoxy resins with the goal of developing new materials that perform longer and better without breaking. The group uses a multidisciplinary approach involving chemistry, mechanics and materials science.

Experts used to improve epoxy toughness by adding butadiene-based copolymers or micro-fillers like silica. Pearson experiments with rubber-toughened epoxies that contain rubber particles orders of magnitude smaller than those used in conventional rubber-toughened epoxies.

Pearson attributes his success to the recent advent of triblock terpolymers-based toughening agents that selfassemble at the nanoscale. Filled epoxies containing glass beads 20 nm in size surely could not be as tough as those 2 microns in size or larger. or could they?

“Conventional wisdom, based on previous published studies, was that larger filler particles were more effective in toughening epoxies,” says Pearson. “But we have all been surprised by the amount of toughness these nanosize fillers can provide. moreover, just a little bit of nano-silica can cause significant improvement in toughness in conventional rubber-toughened systems.”