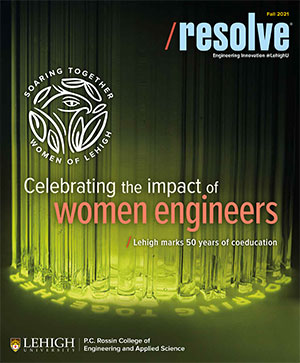

When asked to put an engineering spin on the Soaring Together logo for the cover of this special issue of Resolve, Lehigh’s Design Labs team, including Wilbur Powerhouse assistant manager Michelle Rodriguez ’21, mechanical engineering student Simeon Krizan ’23, and managing director Brian Slocum, rose to the challenge.

When asked to put an engineering spin on the Soaring Together logo for the cover of this special issue of Resolve, Lehigh’s Design Labs team, including Wilbur Powerhouse assistant manager Michelle Rodriguez ’21, mechanical engineering student Simeon Krizan ’23, and managing director Brian Slocum, rose to the challenge.

In taking on this project, the team showcased the multitude of methods and machines available through Lehigh's Design Labs, a network of fabrication facilities across campus that give students the resources to craft projects from a variety of materials.

Long-time Lehigh collaborator Ryan Hulvat and the team from Meris were tapped to photograph the creative process.

3D Printing

The long-exposure image (above, left) featured on the magazine cover reveals the full path of the ultraviolet laser of a stereolithography (SLA) 3D printer as it cures each letter of the Soaring Together logo from a vat of resin. Wilbur Powerhouse's FormLabs Form 3 SLA 3D printers create high-resolution 3D custom parts through additive manufacturing. The completed print (above, right) is then rinsed in isopropyl alcohol and placed in a a UV light chamber to fully dry and harden. At that point, it assumes the full properties of the resin. Different resins have distinct qualities, such as hardness, flexibility, and elasticity.

Laser Cutting

Rodriguez, who is a mechanical engineering alumna, uses a Dremel Digilab Laser Cutter to etch the Soaring Together logo into a small slab of wood. This machine employs a controlled 40-watt laser to cut and etch a variety of materials, including wood, cardboard, and acrylic.

CNC Machining

Krizan uses a Computerized Numerical Control (CNC) machine to carve the Soaring Together logo out of a piece of aluminum. The Tormach 1100M CNC machine is the newest addition to the Design Lab Student Fabrication Shop in Wilbur Powerhouse. Unlike additive manufacturing (aka 3D printing), a CNC machine works by subtractive manufacturing, removing material from a piece of stock to reveal the desired design. It's like sculpting versus carving.

Getting the perfect shot

The photography team, led by Hulvat (center), took hundreds of shots over the course of a day to capture these eye-catching images.