When designing an airplane, a bridge, or a building, engineers face trade-offs among factors like material strength, weight, and cost.

For decades, engineers have employed mathematical frameworks—through an approach called topology optimization—to determine efficient material distribution and connectivity in design, resulting in lightweight, durable, and high-performance solutions.

For decades, engineers have employed mathematical frameworks—through an approach called topology optimization—to determine efficient material distribution and connectivity in design, resulting in lightweight, durable, and high-performance solutions.

Today, thanks to advances in computational tools and the rise of additive manufacturing, says Natasha Vermaak (pictured), an associate professor of mechanical engineering and mechanics, the benefits of topology optimization for materials design are within reach for a much wider swath of audiences and industries.

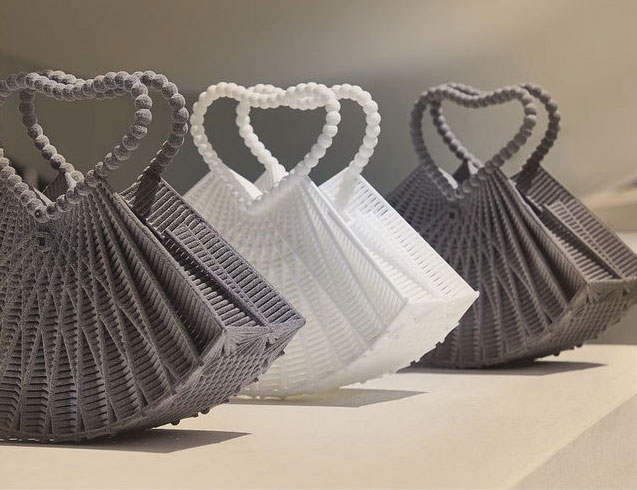

That includes the manufacturing of products such as medical devices and consumer electronics (where critical materials can be scarce and/or expensive), as well as more unexpected fields like fashion, where sustainability concerns are taking on greater focus.

Additive manufacturing (also known as 3D printing) can produce geometrically complex components, Vermaak says, which allows the near-full use of the freeform structural evolution of topology optimization.

In 2020, Vermaak received the Frontiers of Materials Award from The Minerals, Metals & Materials Society (TMS). This award is given to top-performing early-career professionals and includes the opportunity to organize a symposium and curate a collection of related articles for a special issue of The Journal of the Minerals, Metals & Materials Society (JOM).

Vermaak’s vision for her symposium on leveraging materials in topology optimization stemmed from her interdisciplinary mindset and her interest in understanding and implementing tools and methods from disparate fields.

“I wanted to engage researchers, designers, and artists around the topic of the optimization of materials and structures, with additive manufacturing as a shared language,” she says.

With that in mind, Vermaak contacted innovators Julia Daviy and Virginia San Fratello. Daviy has paved the way for sustainable digital 3D-printed clothing, accessories, and jewelry, while San Fratello is a professor, author, and thought leader in additive manufacturing, architecture, and interior design.

Together, they published the article, “Leveraging Materials in Topology Optimization: Inspiration from Design, Fashion, Art, and Architecture,” which prefaced a special issue of JOM in 2021. They are also preparing research proposals on topics such as design for additive manufacturing of structures that are seeded with end-of-life pathways (like fungi), and simultaneously optimizing manufacturing processes and materials for bio-textiles.

Combining diverse perspectives, they say, can lead to inventive approaches.

“Most of the challenges that we face today cross disciplinary boundaries, and a diversity of perspectives is needed in order to drive impactful innovation,” Vermaak says.

For example, engineers and fashion designers working together can identify production models, based on both digital design and additive manufacturing, to better use recyclable/biodegradable materials with the potential to achieve near-zero levels of waste, carbon emissions, and water usage.

As a researcher, Vermaak sees untapped potential in thinking more broadly about materials, waste, economy, craft, and design.

“When we ask a broader audience of designers what they consider as materials objectives and constraints, and which materials they find most challenging to work with and why, new research questions that may require reimagining topology optimization frameworks themselves may emerge.”