It takes just a relative handful of rogue cells to cause cancer by dividing uncontrollably and spreading to the wrong regions of the body.

Similarly, in the interface, or grain boundary, of a material, one grain out of 10,000 can undergo a much more sudden and dramatic growth spurt, consume its smaller neighbors, and greatly alter the properties of the material.

The phenomenon has perplexed engineers for decades, says Martin Harmer, director of Lehigh’s Center for Advanced Materials and Nanotechnology.

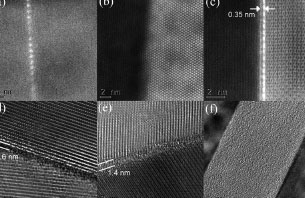

Harmer believes he has made a fundamental discovery that could help engineers better tailor the properties of ceramics. Using Lehigh’s aberration-corrected transmission electron microscope, Harmer and his student, Shen Dillon, have identified six grain-boundary “complexions” in the ceramic alumina (Al2O3), each with a distinct rate of grain growth. The complexions can be controlled by making changes, often subtle, in chemistry and temperature, Harmer says.

“We tested types of alumina with different dopants, noticed remarkable trends in the data, and used TEM to image the atoms at the grain boundaries,” says Harmer. “We matched the six growth rates with six fundamental types of interfaces, and correlated each type of interface with a specific rate of grain growth.”

Scientists have long assumed that there were only two or three different types of grain boundaries in alumina, says Harmer.

Harmer will give a plenary lecture on his discovery in October 2008 at a symposium of the American Ceramics Society, which is awarding him the 2008 Sosman Award. The prize is the most prestigious given by the Society.

Harmer predicts his discovery will make it easier for engineers to control the critical rate of growth at grain boundaries. The interfaces play a key role in the creation of ceramic solids from powders and in the mechanical, chemical and other properties of the bulk material. For example, he says, slowing the rate of grain-boundary growth facilitates the formation of nanograins, which can make a material stronger and more transparent.

“Complexions are going to be very relevant for fabricating nanograined materials,” says Harmer. “They will help us avoid the transition from slow-moving to fast-moving grain boundaries that happens in a relative split second and is triggered by a change in temperature of only a few degrees.”

“This fundamental work has the potential to lead to materials with superior properties, lighter weight and higher strength,” says Dan Powell, program manager at NASA’s Goddard Space Flight Center in Maryland. “With applications, we might see a 10 to 40 percent improvement in fracture strength that could enable us to control anomalies that come up in space travel.”