Out at the edge of the known universe, billions of light-years from the earth, the elusive secrets to the beginning of time and space are speeding ever farther and faster from our grasp.

Closer to home, thousands or millions of lightyears away, clues to the origins of stars and planets are concealed in giant clouds of dust where new heavenly bodies continue to take shape.

Human beings have not ceased wondering since first gazing in awe at the nighttime sky: How did the universe come into being? How do stars and galaxies form? Are there other planets in the universe capable of sustaining life?

The National Aeronautics and Space Administration will soon take a small step into space to tug at the veil shielding those mysteries.

In 2013, NASA will launch the James Webb Space Telescope (JWST) one million miles out into space, four times farther from the earth than the moon, and 2,500 times farther than the Hubble Telescope, which the JWST will replace.

The JWST will be like no telescope before it. A perfectly positioned space laboratory, it will observe the deep universe by blocking out the brighter light of closer objects to capture the faint light of vanishing galaxies.

Designing and operating the JWST is a huge engineering effort involving the European Space Agency, the Canadian Space Agency, Northrop Grumman Space Technologies and others. The telescope will be sent into space on an Ariane launch vehicle.

Lehigh is playing a critical role in a system of microshutters (see page 12) that will help the JWST capture selected infrared signals from the edge of the universe and thus observe the most distant galaxies. That project is part of a larger collaboration between Lehigh and NASA that supports research vital to space exploration while seeking to inspire the next generation of scientists and engineers.

That joint effort, the Lehigh University/MidAtlantic Partnership for Nanomaterials, has spawned a dozen research projects involving 14 Lehigh faculty members. In 2006, Lehigh and NASA’s Goddard Space Flight Center (GSFC) in Maryland received $4 million from a congressional appropriation. Later, under a cooperative agreement signed by Lehigh and GSFC, NASA pledged to support research in Lehigh’s Center for Advanced Materials and Nanotechnology (CAMN), as well as internships and research projects for Lehigh students.

The partnership also grants NASA access to Lehigh’s world-class electron microscopes, which will help researchers develop new materials and devices for space exploration.

“We regard the Lehigh-NASA relationship,” says GSFC program manager Dan Powell, “as a long-term strategic partnership, and not just a group of highvalue development efforts.”

Lehigh and NASA choose research topics that couple NASA’s needs with Lehigh’s strengths. Lehigh has also obtained grants from the Pennsylvania Infrastructure Technology Alliance (PITA), the Pennsylvania Space Grant Consortium and other agencies to support internships and related research.

Many Lehigh-GSFC projects have interest for other funding agencies, says Gene Lucadamo, Lehigh program manager for the partnership. Carbon nanotube sensors that detect noxious gases in spacecraft, for example, are useful for bioterror prevention efforts by the Departments of Defense and Homeland Security. Transparent ceramics for tougher spaceship windows can be applied to the armored glass required by military vehicles.

These “cross-links,” says Lucadamo, make it possible to leverage funding from other agencies. In addition, the CAMN’s Lehigh Nanotechnology Network includes two dozen company members that can design, fabricate or utilize the new materials and devices generated by research projects.

“The structure of our partnership enables us to pursue other research opportunities as they emerge,” says Powell. “If we hit barriers in existing projects, we try to be flexible enough to pursue lateral pathways.

“Lehigh has received only a small fraction of the support that some other universities receive, yet we’re seeing real results in nanocharacterization and new nanomaterials.”

CAMN director Martin Harmer is principal investigator for the partnership. David Williams, former vice provost for research at Lehigh (see page 8), and William Michalerya, associate vice president for government relations, played key roles in establishing the alliance.

Tiny behaviors of huge importance

Telescopes, spaceships, robots and many other devices vital to space exploration can be made to function more efficiently and reliably if engineers understand how their tiny constituent materials behave in the hostile environment of space.

Nanocomposites, nanoribbons and other nanomaterials, for example, should enable engineers to fabricate lighter-weight space vehicles with superior material properties – without sacrificing strength.

But such advantages can only be gained with an improved knowledge of the way these materials behave at the atomic scale.

For this reason, Lehigh’s Nanocharacterization Laboratory is critical to the Lehigh-NASA collaboration. Lehigh, with 14 instruments, possesses one of the world’s most extensive collections of electron microscopes. Using two aberration-corrected microscopes – a JEOL 2200FS transmission electron microscope (TEM) and a VG HB 603 scanning transmission electron microscope (STEM) – researchers can resolve images to 0.1 nanometer, about half the width of an atom, and can determine the chemical identity of individual atoms in crystalline materials.

Lehigh experts are constantly refining microscopes and developing new analytical techniques. These upgrades make it possible to determine a material’s mechanical, chemical and electrical properties, as well as its structure and composition, at the nanoscale.

These analyses can be performed remotely. Lehigh engineers operated the JEOL 2200FS TEM from the Microscopy and Microanalysis 2006 meeting in Chicago, and have teamed with NASA engineers to set up a remote instrument terminal that could enable NASA scientists to operate the instrument anywhere.

“Internet2 and improved software developed by JEOL are making it more viable for people at NASA to do experiments in our labs,” says Chris Kiely, director of Lehigh’s Nanocharacterization Laboratory. “The only thing you cannot do remotely is to load a specimen. Everything else – setting the apertures, controlling the alignment and acquiring data – can be done remotely.”

The Lehigh-NASA partnership includes a half-dozen microscopy-related projects. In one, CAMN research scientist Lolita Rotkina is enhancing the capabilities of the JEOL 2200FS TEM with a novel combined characterization tool – a low-current measurement circuit and scanning probe fabricated by a smaller company called Nanofactory, for Gatan Inc., a leading manufacturer of electron microscopy ancillary equipment. The tool can locate and image an object as small as a single carbon nanotube, and measure its electronic conductivity and simultaneously manipulate it using a piezodriven probe. This tool has potential applications both to the analysis of materials like reinforced nanocomposites and also to molecular electronic devices, which are a focus of current NASA research.

In another collaboration with Gatan, researchers have attached an X-ray ultra microscopy (XuM) system to Lehigh’s XL-30 SEM to study volcanic ash, fly ash, biocompatible glass, precipitates in aluminum alloys, clay-reinforced polymer nanocomposites and other materials. The XuM work is being led by CAMN research scientist Carol Kiely.

XuM obtains an image by using a CCD camera to measure the intensity of the X-rays transmitted through a specimen after it has been bombarded by X-rays emitted from a target located within the microscope. Lehigh and the Lawrence Livermore Laboratories are the only two places in the U.S. currently with such an XuM.

The XuM-SEM combination, says Chris Kiely, enables engineers to obtain images from the interior of a relatively thick sample without damaging or destroying it.

“With XuM, you can see through half a millimeter of polymer, and about 100 microns of metal foil, to obtain an image of a material’s internal structure,” says Kiely. “Using XuM, we have created 3-D reconstructions of precipitates containing heavy atoms sitting within an aluminum matrix.

“XuM is also very effective at visualizing how a crack propagates through a material. In studying polymers reinforced with silica or clay particles, XuM has given us the clearest images yet of crack tip morphology.”

Lehigh geologists have used the new XuM to study the shapes of pores within volcanic ash particles, says Kiely. NASA may want to use XuM to study lunar dust morphology to assess its abrasive effect on the mechanical parts of space vehicles.

Toward higher-performing space vehicles

XuM is proving particularly useful in two other Lehigh-NASA projects.

In a collaboration with GSFC’s Powell, Wojciech Misiolek, director of Lehigh’s Institute for Metal Forming, is seeking to disperse boron nanoribbons in aluminum matrix composites to improve the strength and stiffness of the composites and thus reduce the weight of the composite structures. The materials are used in aerospace applications, and NASA hopes Misiolek’s work leads to lighter, stronger space vehicles with improved thermal stability and fuel efficiency.

“We believe that nanoribbons, because of their size and ability to disperse, will function as a strengthening agent for aluminum matrix systems,” says Misiolek, who collaborates with experts in Europe, Australia, New Zealand and Brazil.

“At present, aluminum matrix composites dispersed with microscale powders of silicon carbide or alumina are used in the automotive and aerospace industries. We’re hoping to improve the mechanical properties of these composites by 30 percent with nanoribbons of boron.”

In a second project, nanoparticles of silica and rubber are demonstrating the potential to increase the interlaminar fracture toughness of carbon-fiber composites, which are also used in aerospace applications.

Ray Pearson, director of Lehigh’s Center for Polymer Science and Engineering, studies toughening mechanisms in thermosetting resins used in composites. Low interlaminar fracture toughness has been the “Achilles’ heel” in fiber composites, says Pearson, because resin-rich regions between plies enable flaws and cracks to travel unimpeded by fibers

Engineers have long used microscale particles of rubber to toughen the matrix of composite materials and to improve the interlaminar fracture toughness, says Pearson. A consensus was formed in the 1990s that 200 nm was the optimal particle size and that decreasing that size would decrease the particles’ effectiveness as toughening agents. Pearson, working with the international chemicals giant Arkema Inc., has recorded a five-fold increase of interlaminar fracture toughness in an epoxy resin containing a tri-block copolymer that self assembles into 40-nm rubber nanoparticles. Additional improvements are obtained when a few percent of 20-nm particles of nanosilica are added to the nano-rubber.

“We are continuing to investigate why these nanoparticles are more effective toughening agents than their microscale counterparts,” says Pearson. “We’re particularly interested in finding out what kind of mechanisms the nanoparticles are triggering. What we’ve seen so far is a lot of ductility occurring, because of the presence of rubber nanoparticles, in a material that would otherwise be brittle.”

In other projects, materials scientists led by Prof. Richard Vinci are seeking to control the mechanical properties of thin film materials exposed to the extreme cold of space. Electrical engineers are developing sensor arrays to monitor space environments, and are also studying methods of protecting sensitive equipment on spacecraft from the ultraviolet rays of the sun and the lethal radiation emitted by some planets. Engineers and physicists are studying new ways of dispersing and sorting carbon nanotubes.

Minding the future

The relationship between Lehigh and NASA dates to the early 1970s, when the space agency asked Joseph Goldstein, former vice president for research at Lehigh, to study meteorites and moon rocks.

In 1983, Mohamed El-Aasser, Lehigh provost and professor of chemical engineering, helped design a reactor that, in zero gravity aboard the Challenger STS-6, synthesized the first products ever made in space – polystyrene latex microspheres for calibrating microscopic objects.

In 2005, seniors in Lehigh’s failure-analysis class became the first college students in the U.S. to be asked by NASA to evaluate debris from the Columbia space shuttle.

As part of the current Lehigh-NASA partnership, five Lehigh undergraduates are doing summer internships at GSFC. NASA is also sponsoring two teams of students in Lehigh’s Integrated Product Development (IPD) program. One team is designing a boom that will stabilize a spacecraft against the earth’s gravity. The second is helping to design a special vacuum chamber that will simulate the environments on the moon and on Mars as they pertain to dust migration and charging. Both teams are supervised by former NASA astronaut Terry Hart, a member of Lehigh’s Class of 1968 and an adjunct professor of mechanical engineering and mechanics at the university.

Mindful of the need to inspire future engineers and scientists, Lehigh faculty and students lead projects at two nearby NASA Explorer Schools – Harrison-Morton Middle School in Allentown, Pa., and Broughal Middle School in Bethlehem, Pa. The outreach efforts at these and other schools are led by Henry Odi, executive director for academic outreach at Lehigh, and Andrea Harmer, CAMN director of Web-based education.

Lehigh is furnishing Broughal Middle School with GIS (Geographic Information Systems) technology, satellite images and remote sensing. Broughal students have toured Lehigh’s microscopy labs, and will learn to use Lehigh’s microscopes remotely.

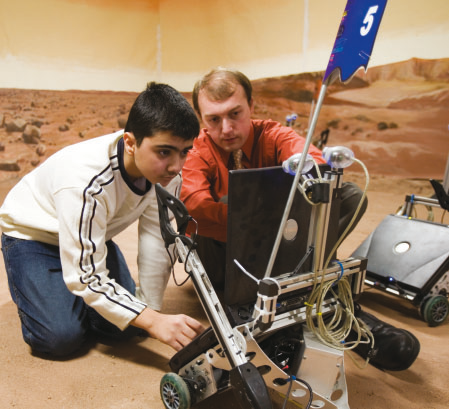

Students at Harrison-Morton are not waiting for official approval to commence their own exploration of space. With help from Lehigh, which has leveraged a grant from NSF’s STEM (Science, Technology, Educational and Mathematics) program, the middle school has built a lifelike Martian landscape in its basement. In their technology classroom on the second floor, eighth-graders learn the basics of computer programming from Lehigh students and professors. Then, like real engineers at mission control, the students guide the robots across the rocky “Mars Yard” terrain two floors below and direct them to fetch rocks to analyze.