Tim Marks ’04 and Pat Clasen ’04 have come full circle with Lehigh University’s Integrated Product Development (IPD) program.

A few blocks from Lehigh’s campus, in the house they rented as undergrads, Marks and Clasen run EcoTech Marine LLC, an aquarium equipment company that was their IPD project in 2003.

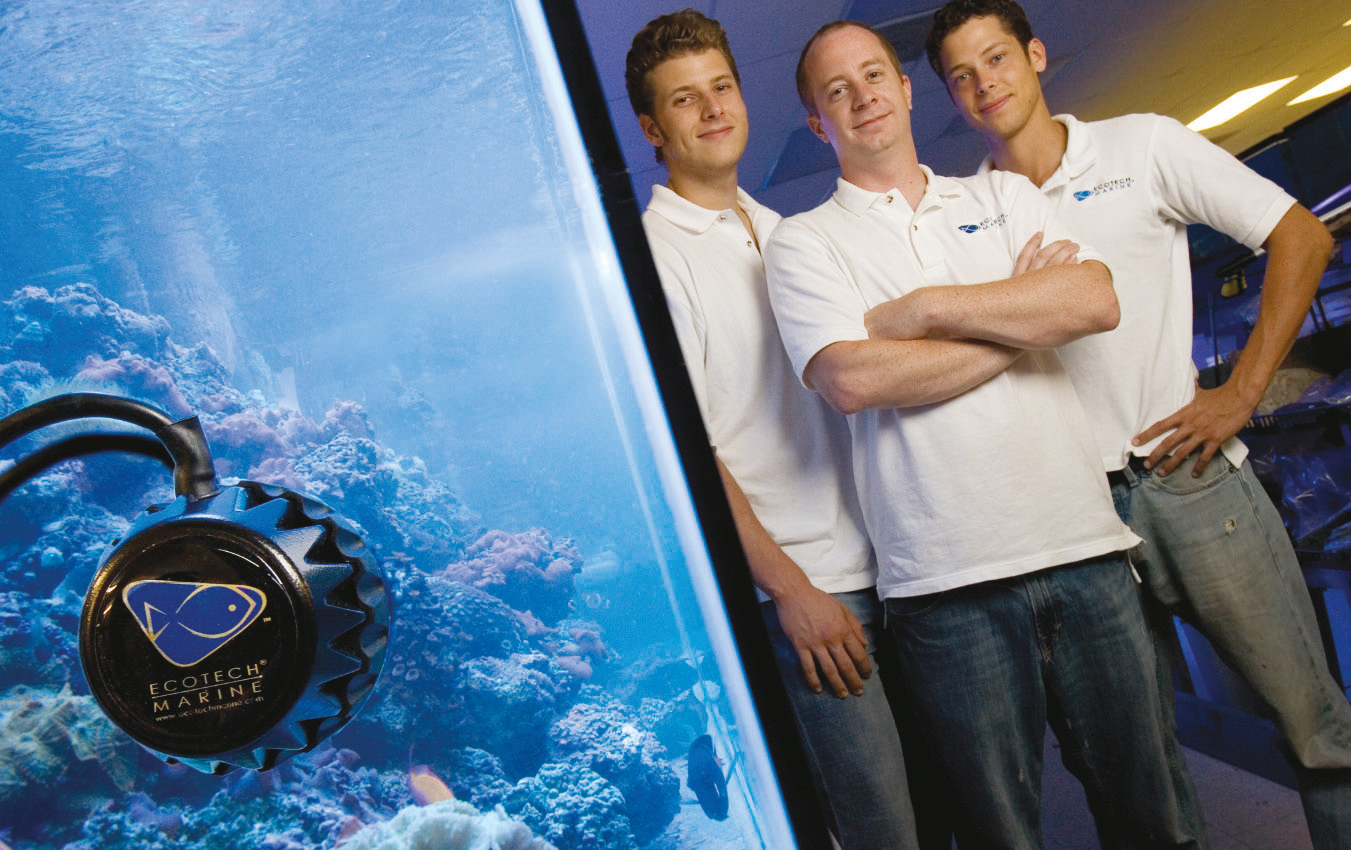

Now, as they look to double their 2006 sales of $500,000, Marks, Clasen and their business partner, Justin Lawyer, have taken six current Lehigh IPD students under their wing.

In Lehigh’s IPD program, teams of engineering, business and design students work for a year to design, make and market new products for sponsoring companies like GM, B. Braun and even NASA.

A handful of IPD teams have received funding from Lehigh to form their own companies, or, in the case of Marks and Clasen, to build on existing companies.

EcoTech’s partners are the first IPD alumni to sponsor IPD students of their own.

EcoTech Marine owes its genesis to the Internet. It was in a chat room for aquarium enthusiasts that Marks met Lawyer, who holds a B.S. in professional physics from the University of Oklahoma. The two founded EcoTech Marine in 2001. Clasen joined the company in 2002.

EcoTech’s first product was the ETM Kalkwasser Reactor, which automatically replenishes and maintains levels of calcium and alkalinity in coral reef aquariums. The company’s second product, and the source of most of its sales, is the patented VorTech propeller pump.

Magnetic attraction is the key to the VorTech. A magnet made of neodymium, a rare earth metal of exceptionally strong magnetism, enables a BLDC (brushless DC) motor outside the aquarium to adhere, through glass as thick as three-quarters of an inch, to a propeller inside the tank. The magnet transmits torque from the motor to the interior propeller, which circulates the water inside the aquarium. A knob on the tank’s exterior adjusts the motor’s speed.

The magnet gives the VorTech several advantages. It removes the need to drill holes through the side of the aquarium to connect the motor to the interior propeller. Electricity is kept outside the tank, and the shaft seal and housing gasket, which can cause leaking, become unnecessary. The VorTech also greatly reduces the amount of heat transferred from motor to tank water.

The BLDC, although expensive, offers additional advantages. It is 50 percent more efficient than most other motors but much lighter and smaller. Because it is brushless, it is longer-lasting.

Future plans for the VorTech include a wireless driver that will enable pumps at opposite ends of a large saltwater reef aquarium to pulse in unison and thus communicate with each other.

EcoTech is expanding beyond the aquarium business. Last year, the company received a call from a man who thought the VorTech could improve the spa industry. The man said water was leaking into his spa motor, which, as in a typical aquarium, is connected to an interior propeller through a hole in the spa tub wall. The man sent EcoTech a sample spa basin, which Marks, Clasen and Lawyer are studying in their prototype room.

EcoTech recently formed a spinoff company, EcoTech NanoSystems, and teamed with an outside researcher to seek applications for an environmentally friendly surface coating that inhibits the growth of algae and other organisms. The patented coating has potential aesthetic and energy-saving benefits.

“I found the patents on the Internet,” says Clasen, “and called the researcher to see if his patents were being commercially used. I was a bit nervous, but I thought, ‘What’s the harm?’ He answered in a scholarly voice and told me to contact his tech-transfer office. He’s willing to give us a license, either full or segmented by market. We’re getting outside opinions to examine the viability and profitability of the coating.”

EcoTech is working on this project with Manoj Chaudhury, professor of chemical engineering at Lehigh and a world-renowned expert in adhesion and coatings (See page 5).

“We’re hoping to develop a commercial coating for the sides of houses, for pools, for patio tiles, for aquariums – wherever there is a need to inhibit the growth of algae,” says Clasen.

EcoTech has received grants from Pennsylvania’s Keystone Innovation Zone (KIZ) program, the Ben Franklin Technology Partners, the Agile Manufacturing Program of Lehigh’s Enterprise Systems Center and the Pennsylvania Infrastructure Technology Alliance (PITA). It has won three awards from the National Collegiate Inventors and Innovators Alliance (NCIIA), which promotes the teaching of innovation in higher education.

EcoTech is seeking further funding from Ben Franklin and from the Small Business Development Center, the Pennsylvania Export Finance Program and the Pennsylvania Nanomaterials Commercialization Center.

“We are a good case study for how to use government funding to start a company, out of college, that is targeted to a niche market,” says Clasen.

The funding and financial advice help, as do the varied areas of expertise of EcoTech’s partners – Marks has a B.S. in environmental engineering and an M.S. in mechanical engineering, while Clasen, who holds a B.S. in materials science and engineering, recently completed an M.S. in that field. The company also employs a part-time electrical engineer.

But the IPD program was critical to EcoTech’s growth, the partners say.

“IPD gives students a chance at real success, either by working for a company that sponsors your product or by developing your own company into a career,” says Marks. “It’s not just an academic exercise; it’s an entry to the real world.”