A nanoporous ceramic filter developed by materials scientists at Lehigh could offer relief to kidney dialysis patients.

William Van Geertruyden, adjunct professor of materials science and engineering at Lehigh, says the new filter has the potential to make dialysis sessions shorter and more efficient.

An estimated 370,000 Americans undergo kidney dialysis treatment every year and the numbers are rising. The exhausting process takes up to four hours and must be done three or four times a week.

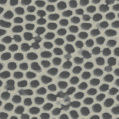

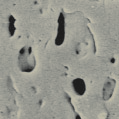

Van Geertruyden, also general manager of EMV Technologies, LLC, in Bethlehem, Pa., says the size and orderly arrangement of pores give his filter a key advantage over traditional polymeric filters.

Measuring nanometers in diameter, the pores in the ceramic filter (above) correspond more closely to the nano-sized toxins in the blood than do the larger pores of standard polymer dialysis filters. These polymeric pores vary in size and, when viewed with a microscope (below), appear in random arrangements of ovals, circles, slits and other shapes.

For these reasons, Van Geertruyden is confident the new filter will increase the amount and rate at which toxins are removed from the blood during dialysis, while decreasing the amount of nutrients removed.

Van Geertruyden, who earned his Ph.D. in materials science and engineering from Lehigh in 2004, developed the new filter with help from Zhongping Huang, assistant professor of mechanical engineering at Widener University, and Wojciech Misiolek, professor of materials science and engineering at Lehigh.

EMV Technologies has received a Small Business Technology Transfer grant from the National Institutes of Health and separate grants from the Pennsylvania Keystone Innovation Zone program and the Ben Franklin Technology Partners.

Van Geertruyden has filed a patent application on the filter.