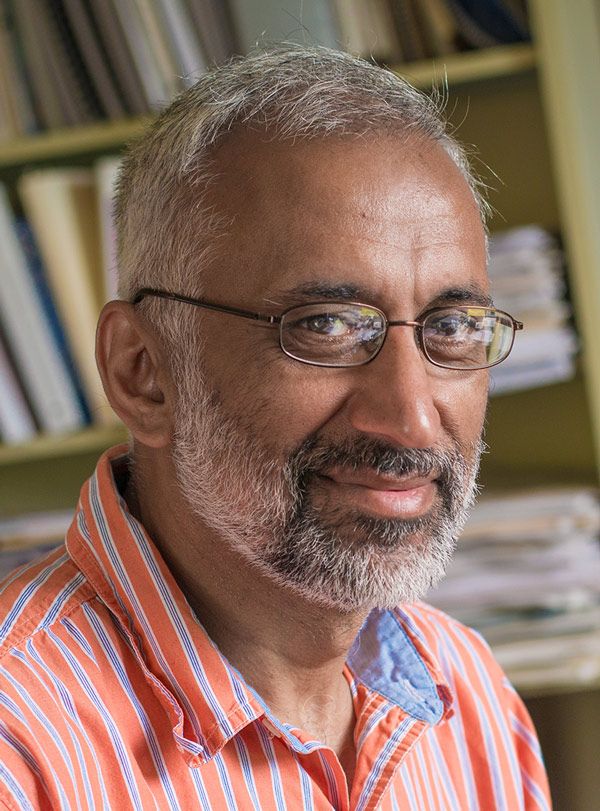

Bioengineering chair Anand Jagota has arrived at a milestone in his 15 years of researching friction and adhesion—one that could lead to innovations in tires, robotics, and biomaterials down the road.

Bioengineering chair Anand Jagota has arrived at a milestone in his 15 years of researching friction and adhesion—one that could lead to innovations in tires, robotics, and biomaterials down the road.

With nearly $2 million in new support from the National Science Foundation over five years, Jagota and collaborators from Cornell University and Michelin North America seek to develop two novel mechanisms to improve friction of soft materials based on bio-inspired design of near-surface structures.

“These are two difficult and new approaches to controlling friction of soft material surfaces and interfaces that have come to light through our previous work,” says Jagota. “This is our fifth and largest grant in this line of research—we continue to find fresh and exciting ideas to investigate.”

Increasing our understanding of friction, Jagota explains, could have wide-ranging implications for society: creating tires that make our cars safer and prevent crashes, improving robots’ ability to grasp and perform intricate tasks, or even just building a better-performing table tennis racket.

Lehigh’s first LEAP HI

The NSF funding comes as a Leading Engineering for America’s Prosperity, Health, and Infrastructure (LEAP HI) Grant Opportunity for Academic Liaison (GOALI). The LEAP HI program supports interdisciplinary, multi-investigator proposals and encourages the engineering research community “to take a leadership role in addressing demanding, urgent, and consequential challenges.” This is the first LEAP HI grant awarded to a Lehigh researcher since the program’s inception in 2017.

Jagota has previously partnered with Michelin North America through the NSF’s GOALI program, which encourages academic-industry collaborations. Michelin manufactures and sells tires for airplanes, automobiles, earthmovers, farm equipment, heavy-duty trucks, motorcycles, and bicycles. The company operates 19 plants and employs 20,000 people in North America, with more than 1,000 in R & D roles.

Nationally, tire manufacturing is a $148 billion industry that is responsible for more than 737,000 jobs, according to the U.S. Tire Manufacturers Association.

“The ability to use surface features to control the friction between surfaces opens many design possibilities; but in order to take advantage of the idea, we need to understand the mechanisms involved and that is what this research will allow us to do,” says Mike Andrews, director of external research for Michelin North America.

The project is also aligned with Lehigh’s Pasteur PhD Partners (P3) Fellowship, a new student-centric graduate training model that provides doctoral candidates in the Rossin College with long-term, hands-on industry experience and mentorship (see “Blazing New Trails”).

Scaling up on multiple levels

Scaling up on multiple levels

Jagota, who is also a professor of chemical and biomolecular engineering and is affiliated with Lehigh’s Institute for Functional Materials and Devices (I-FMD), will continue his long-standing collaboration with Cornell engineering professor Chung-Yuen Hui. The team also includes Constantine Khripin ’08 PhD, a materials performance researcher at Michelin who did his dissertation work in Jagota’s lab.

The new project has origins in Jagota’s earlier work in biomimicry—investigating biological adhesion mechanisms in geckos, lizards, and frogs—but has evolved to a collaboration with industry focused primarily on friction.

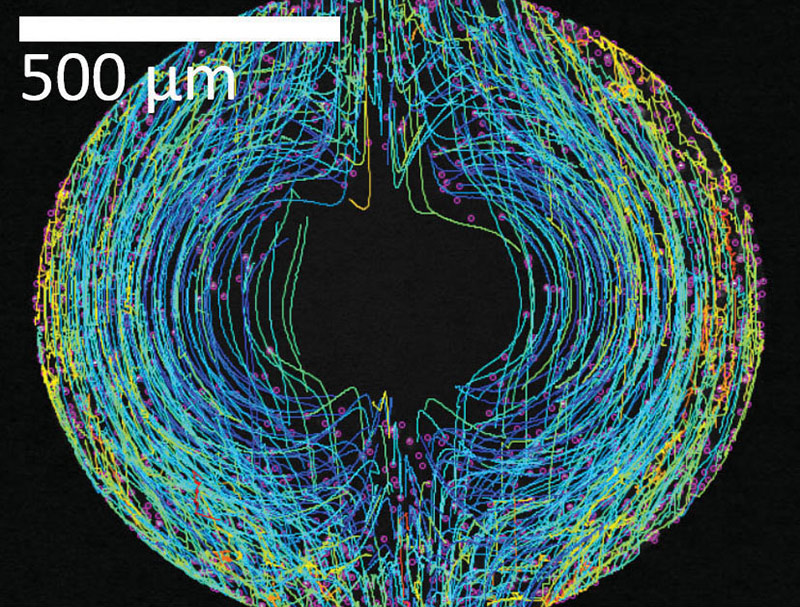

“In making these biomimetic surface structures, employing fibrils or complementary shapes, we’ve been able to create very high sliding friction, which could be used to improve the braking performance of tires,” he says. “We’ve discovered several techniques that can turn friction up or down. Now we’re taking a deeper dive into these mechanisms, some of which are meso-scale versions of molecular level phenomena that underlie the fundamental question of how friction arises between surfaces in the first place.”

The team will investigate two mechanisms based on previous discoveries.

Meso-scale dislocation arrays are interfaces with a periodic array of features that accommodate misorientation by generating meso-scale interfacial dislocations, which can be used to control friction. Employing these arrays in the manufacture of tires and other products comprised of layers of soft materials like rubber could improve product quality, cut down on waste, and open up experimentation with new materials.

The second avenue of research explores a new form of elastic hysteresis based on periodic near-surface patterning of elastic modulus that can be used to set up additional hysteresis to yield significant friction enhancement. The mechanism could enhance friction of tires, especially in wet conditions, and contribute to a reduction in the risk of vehicle collisions and related fatalities.

“Tire manufacturing is a very mature field, so there’s a very different dynamic when it comes to implementing innovation,” says Jagota. “You have to be very, very careful before making changes because of the safety aspect, so there is a deliberate process for applying new ideas. It’s a challenge, but we take that as a positive.”