Copper’s exceptional thermal and electrical conductivity has made it a cornerstone of modern technology. Yet its weakness at high temperatures has kept it out of applications where both strength and conductivity are essential. Superalloys based on nickel and other metals have long filled that role, but they lack copper’s ability to conduct heat and electricity efficiently.

Copper’s exceptional thermal and electrical conductivity has made it a cornerstone of modern technology. Yet its weakness at high temperatures has kept it out of applications where both strength and conductivity are essential. Superalloys based on nickel and other metals have long filled that role, but they lack copper’s ability to conduct heat and electricity efficiently.

Now, researchers from Lehigh and the U.S. Army Research Laboratory (ARL), working with collaborators at Arizona State and Louisiana State universities, have developed a copper-based alloy that defies those limits. Their findings, published in Science, introduce a Cu-Ta-Li (copper-tantalum-lithium) alloy that combines copper’s conductivity with the high-temperature resilience of superalloys. The material could lead to next-generation defense, aerospace, and industrial technologies.

“This is cutting-edge science, developing a new material that uniquely combines copper’s excellent conductivity with strength and durability on the scale of nickel-based superalloys,” says Martin Harmer (pictured, below), Alcoa Foundation Professor Emeritus of Materials Science and Engineering and co-author of the study. “It provides industry and the military with the foundation to create new materials for hypersonics and high performance turbine engines.”

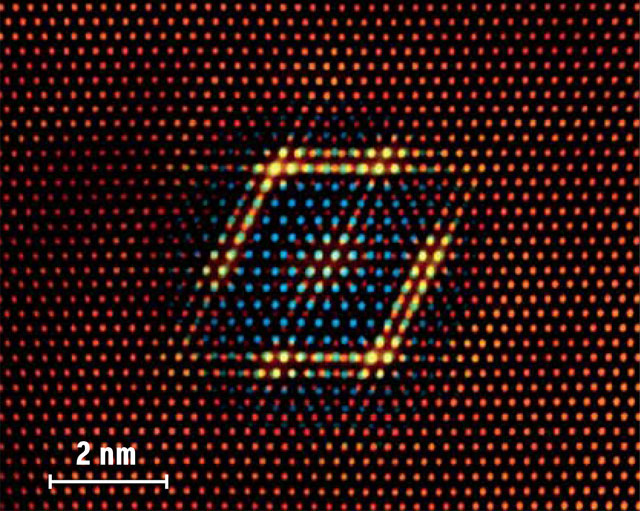

The breakthrough centers on a new strategy for stabilizing copper at extreme temperatures. The team created nanoscale Cu3Li precipitates, which are stabilized by tantalum-rich bilayer “complexions,” or atomic-scale structures that form along grain boundaries. Grain boundaries normally migrate and weaken materials exposed to high heat. Here, the complexions lock the structure in place, maintaining strength even close to copper’s melting point.

The alloy holds its shape under extreme, long-term thermal exposure and mechanical stress, resisting deformation even near its melting point, notes Patrick Cantwell, a research scientist at Lehigh and co-author of the study.

“These tantalum bilayer complexions make the alloy so stable, it can be held near its melting point for over a year without losing its nanostructure,” Harmer says. “It’s unprecedented for copper.”

The Cu-Ta-Li alloy offers a new balance of properties not found in existing materials. By merging copper’s conductivity with superalloy-like stability, the material could impact technologies including turbine engines, thermal management systems, hypersonic vehicles, power generation, and advanced electronics. It also establishes a broader design principle: that atomic-scale features at grain boundaries can be engineered to overcome long-assumed limits in materials performance.

“This discovery opens up an entirely new strategy for alloy design,” says Harmer. “By manipulating what happens at the boundaries, we can stabilize structures in ways that were not previously possible.”

The research builds on more than a decade of collaboration between Lehigh and ARL, supported by a $25 million cooperative agreement to develop advanced metallic alloys. Additional support came from NSF and Lehigh’s Presidential Nano | Human Interfaces Initiative.

The research builds on more than a decade of collaboration between Lehigh and ARL, supported by a $25 million cooperative agreement to develop advanced metallic alloys. Additional support came from NSF and Lehigh’s Presidential Nano | Human Interfaces Initiative.

ARL has been awarded a U.S. patent for the Cu-Ta-Li alloy, underscoring its potential in strategic defense applications. And earlier this year, the Falling Walls Foundation, based in Berlin, named Harmer’s involvement in the team’s discovery as one of the Top 10 Global Science Breakthroughs of 2025 in the physical sciences category. Falling Walls highlights advances that “break walls” in science and society.

“This is a profoundly humbling honor,” says Harmer. “Falling Walls highlights not only the science but the human aspiration to push boundaries. To be recognized alongside such extraordinary work from around the world is a privilege. This research was a true team effort of world-class collaborators.”

The team is now working to measure the alloy’s thermal conductivity against nickel-based alternatives and explore ways to adapt the design approach to other metals.

“This is a new design strategy for materials at the atomic level,” he says. “It’s about turning what was once seen as a weakness into the material’s greatest strength.”

For Lehigh, the breakthrough reflects institutional strength and a history of collaboration in microscopy and materials research. “This is a great example of how federal investment in fundamental science drives U.S. leadership in materials technology,” Harmer says. “Scientific discoveries such as this are key to strengthening national security and fueling industrial innovation.”