For the U.S. Army, figuring out where to locate ammunition storage facilities in an area of operations is currently a manual, time-consuming, and labor-intensive process—with little guarantee of the ultimate quality and effectiveness of the design, according to industrial and systems engineering professor Robert Storer.

For the U.S. Army, figuring out where to locate ammunition storage facilities in an area of operations is currently a manual, time-consuming, and labor-intensive process—with little guarantee of the ultimate quality and effectiveness of the design, according to industrial and systems engineering professor Robert Storer.

In short, he says, “it presents an ideal opportunity for automated optimization algorithms.”

Storer and a team of Rossin College researchers (fellow industrial and systems engineering professor professors Larry Snyder and Luis Zuluaga, computer science and engineering professor Michael Spear, and ISE PhD student Ruby Zhuo) have seized the opportunity: With support from a three-year, $264,000 Army grant, they are building algorithms for automating the design of layouts for ammunition support activities.

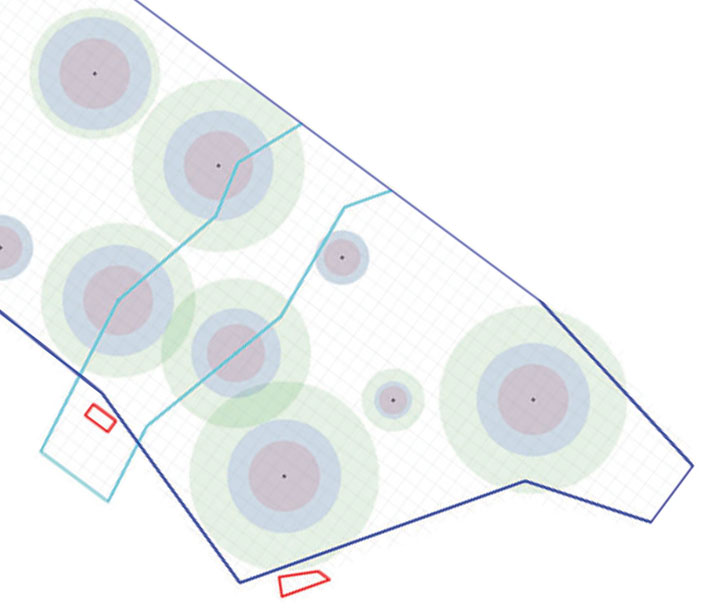

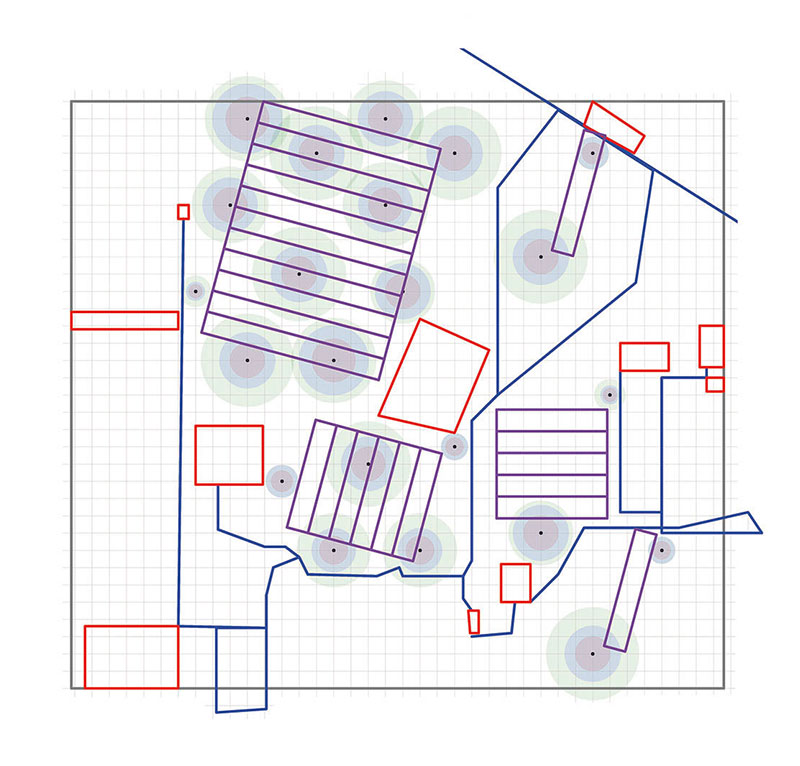

The main focus is the positioning of field-based ammunition supply points (ASPs) and ammunition transfer points, facilities that need to be designed and built expediently during field operations. Because of their explosive contents, the facilities must be located at safe distances from each other, as well as from roads, buildings, and other vulnerable sites.

The main focus is the positioning of field-based ammunition supply points (ASPs) and ammunition transfer points, facilities that need to be designed and built expediently during field operations. Because of their explosive contents, the facilities must be located at safe distances from each other, as well as from roads, buildings, and other vulnerable sites.

The Army’s existing process, Storer says, relies extensively on the experience of ammunition chief warrant officers. Aided by mapping and graphical software, the designer plans the ASP layout by locating the various facilities on a map, observing the flaws in the design, and then reconfiguring it in a manual, trial and error procedure.

The team will automate the process by creating algorithms that will position ASP facilities in a design that optimizes the area used, he explains, while adhering to minimum distance requirements, set by the Department of Defense, within an appropriate measure of risk.

CREDIT: Illustrations by Yihe (Ruby) Zhuo