Wind turbine blades, like those atop the Pocono Mountains in northeast Pennsylvania, can cost upwards of $100,000 a blade, says Raymond Pearson, director of the Center for Polymer Science and Engineering.

So it’s no surprise that manufacturers and power generation companies are interested in making blades that produce electricity for as many years as possible. To prolong the lifespan of these futuristic “windmills,” Pearson’s group is investigating rubber nanoparticles that could toughen the glass-reinforced, epoxymatrix composites out of which the massive blades are made.

“If wind turbines are guaranteed to last five years, and we can lengthen that by a factor of 2, it would go a long way toward making wind energy cheaper,” says Pearson. “We haven’t gotten to the point of testing actual blades, but we’re seeing some promising results on laboratory test specimens.”

Pearson’s experience with triblock polymers, which self-assemble on a nanoscale, has led to a partnership with Arkema Inc., a French company with research facilities in King of Prussia, Pa. The researchers are studying the use of diblock polymers in turbine blades. Diblock polymers are preferable to commercial triblock copolymers because the resulting rubber-toughened epoxies flow better during turbine blade manufacturing.

Arkema has supplied Pearson’s group with diblock polymers that self-assemble in epoxy resins, enabling the researchers to control and potentially optimize the performance of the composite material. The group is assessing the type of microstructures that provide the best properties for making blades that would last longer than the current generation of turbines.

Pearson’s group also is experimenting with diblock polymers to increase the fracture toughness of printed circuit boards, which are now subjected to higher solder reflow temperatures. Such high temperatures are necessary because the use of environmentally unfriendly lead tin solder is now banned in many countries. The challenge is to determine the optimum structure of the diblock copolymer additives that will reduce cracking.

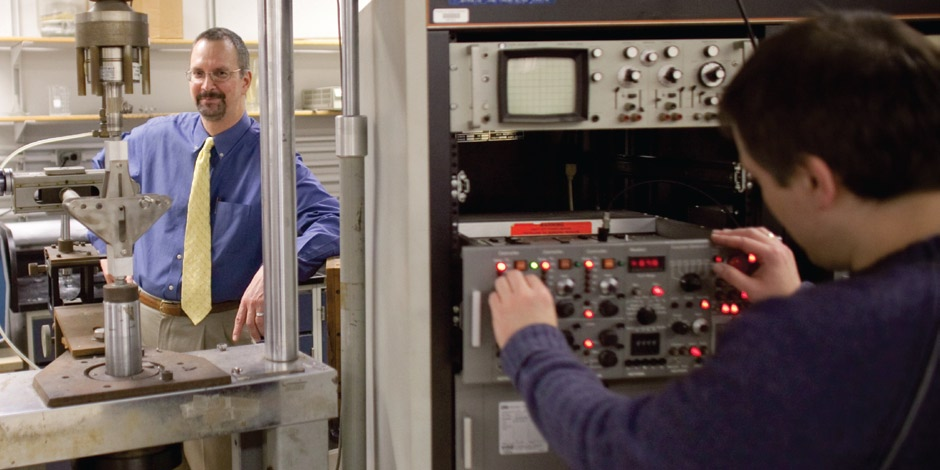

Electron microscopy and fatigue fracture testing are conducted in Lehigh’s Center for Advanced Materials and Nanotechnology. The work is funded by the Pennsylvania NanoMaterials Commercialization Center.